Continuous separation device for p-benzoquinone crystals

A separation device and a technology for p-benzoquinone, which are applied in the field of continuous separation equipment for p-benzoquinone crystallization, can solve the problems that a stripper cannot work continuously, have an unreasonable structure, and discharge a lot of pollutants, so as to improve the continuous work and efficiency. Low, good economic and social benefits, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

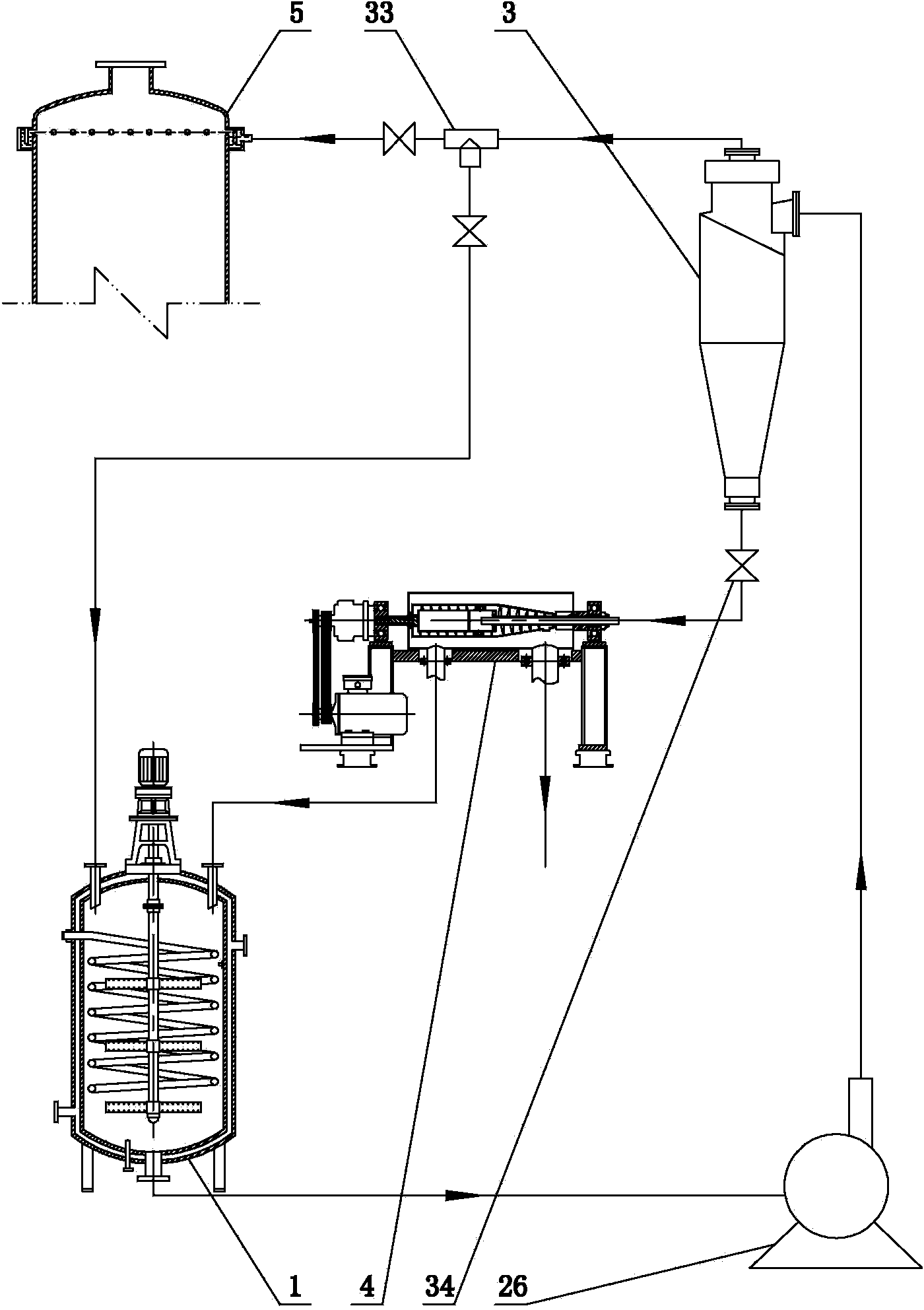

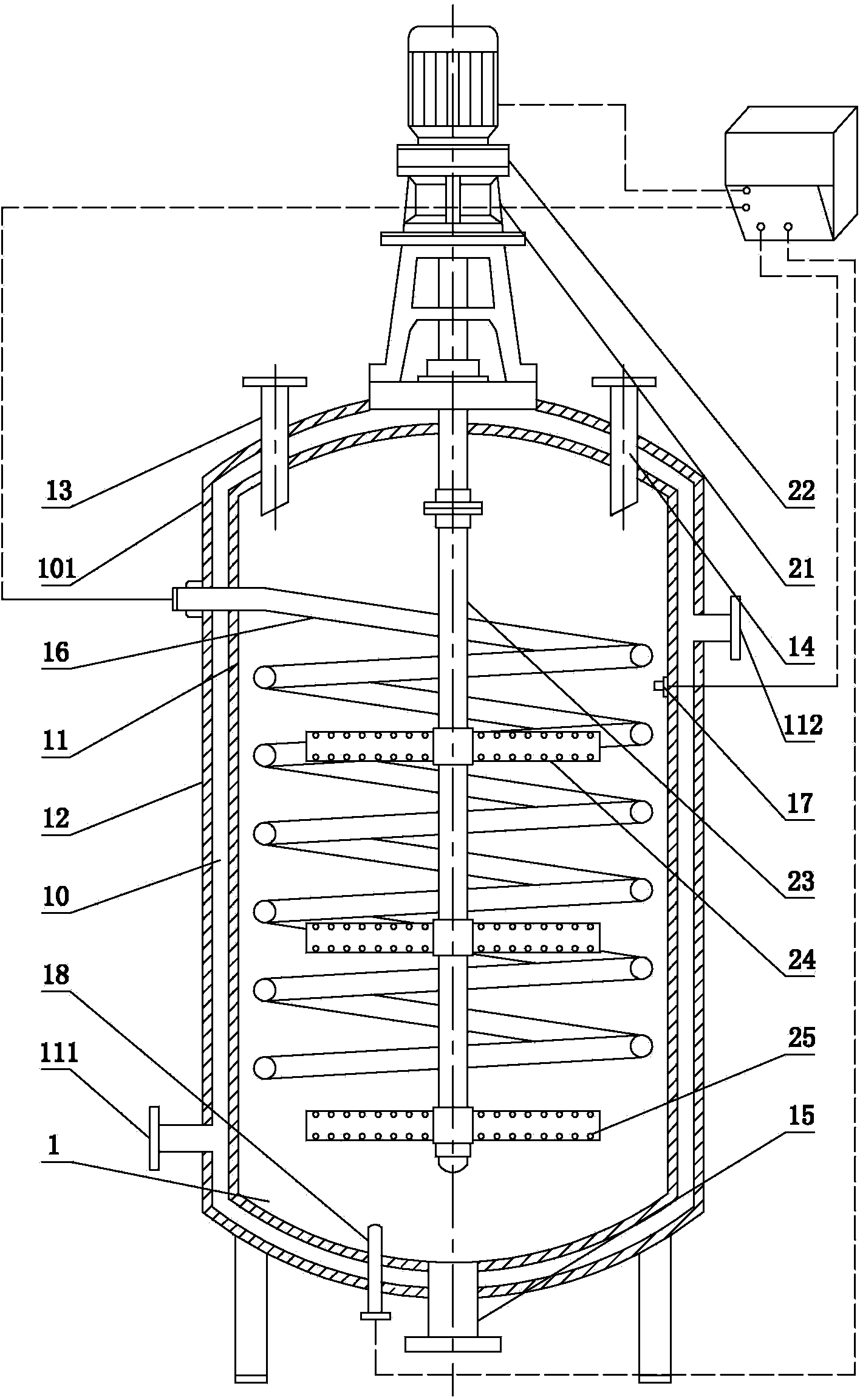

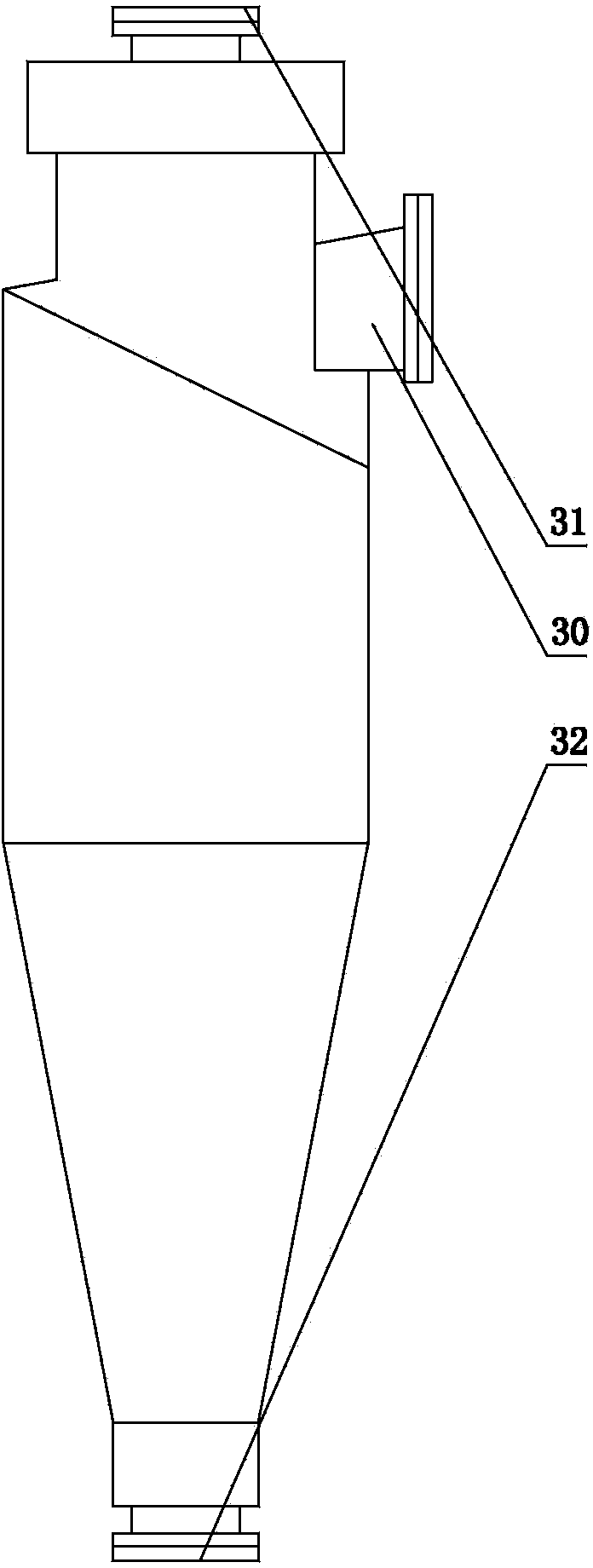

[0019] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. figure 1 It is a structural schematic diagram of the present invention, figure 2 is the schematic diagram of the structure of the crystallization kettle, image 3 is the schematic diagram of the cyclone separator, Figure 4 is a schematic diagram of a horizontal centrifuge, Figure 5 It is a schematic diagram of the structure of a horizontal centrifuge drum. Image 6 It is a structural schematic diagram of the water film generating device on the upper part of the p-benzoquinone stripping tower, Figure 7 Is the schematic diagram of the PLC control circuit.

[0020] It can be seen from the figure that the p-benzoquinone crystallization continuous separation equipment includes a crystallization kettle 1, a cyclone separator 3, a horizontal centrifuge 4, a PLC control circuit and the like. The crystallizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com