A kind of step grinder for pen making

A technology for steps and pens, which is applied in the field of pen-making equipment and utensils. It can solve the problems of troublesome grinding operations, the inability to apply fiber pens, and the inability to adjust the positions of grinding wheels and guide wheels, etc., to achieve flexible and changeable grinding effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

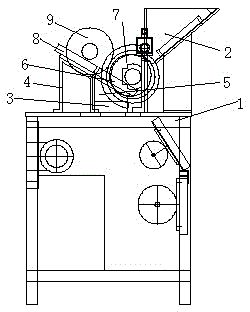

[0010] Combine below figure 1 Specific examples:

[0011] A step mill for pen-making, comprising a frame 1 on which a feeding device 2 is provided, and is characterized in that the frame 1 is provided with a guide wheel horizontal carriage 3 and a high vertical slope 4. The guide wheel horizontal carriage 3 can move laterally on the frame 1, the guide wheel horizontal carriage 3 is provided with a low vertical slope 5, and the low vertical slope 5 is movably provided with a guide wheel The straight carriage 6, the guide wheel straight carriage 6 is connected with a guide wheel 7, and the guide wheel 7 can be adjusted in height under the movement of the guide wheel straight carriage 6, and the high-rise slope 4 A grinding wheel straight carriage 8 is movably provided, and the grinding wheel 9 is connected to the grinding wheel 9. The height of the grinding wheel 9 can be adjusted under the movement of the grinding wheel straight carriage 8.

[0012] Preferably, the inclination dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com