Lightweight automobile steel plate

An automotive steel plate, lightweight technology, applied in vehicle parts, superstructure, transportation and packaging, etc., can solve problems such as high cost, complex manufacturing process, and no complete solution of excess weight, and achieve simple manufacturing process, low manufacturing cost, The effect of rapid and widespread application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation of the present invention is described below through specific examples, and those skilled in the art can easily understand the advantages and effects of the present invention from the content disclosed in this specification. The present invention can also be implemented in other different ways, that is, various modifications and changes can be made without departing from the disclosed scope of the present invention.

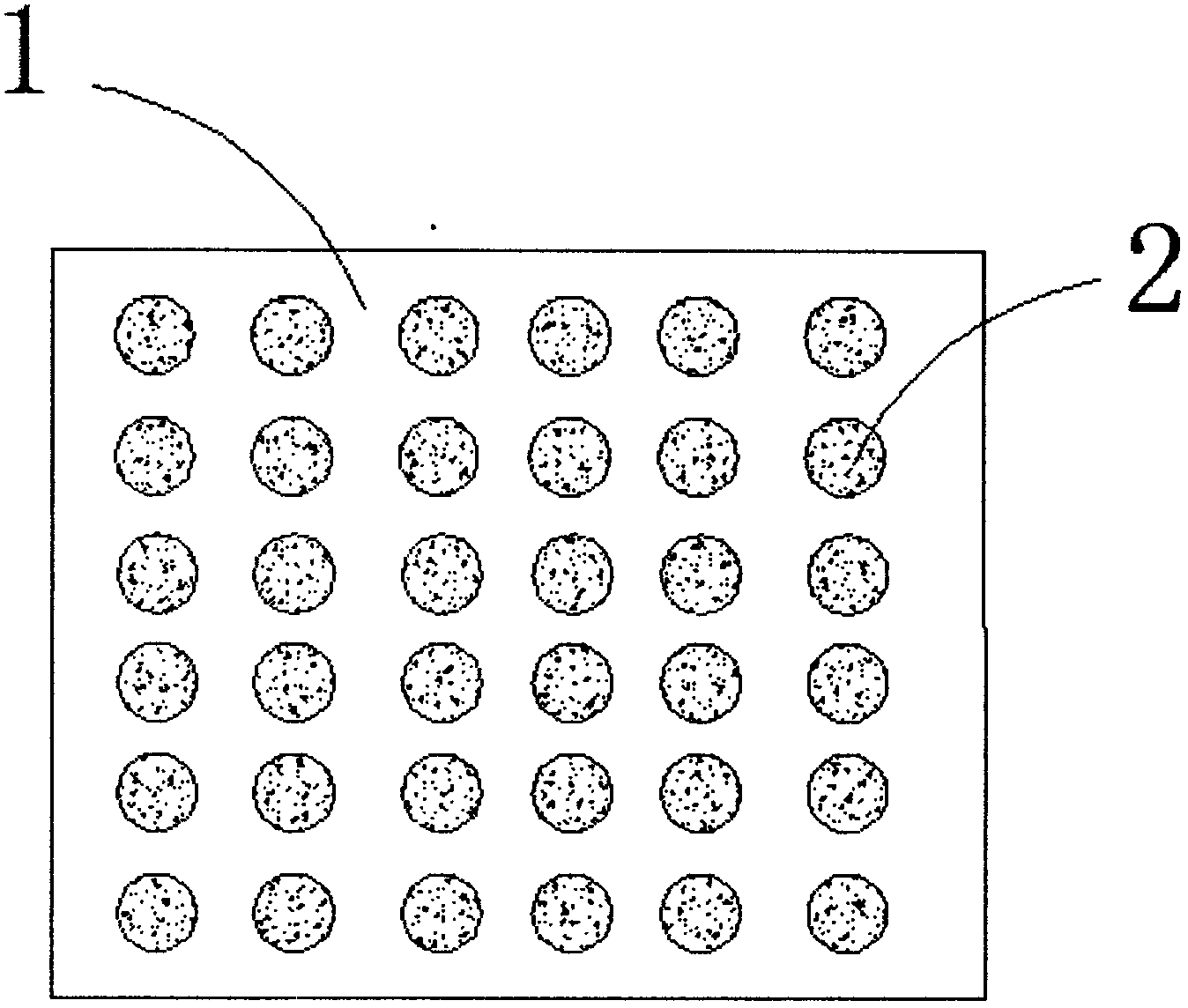

[0012] A light-weight automobile steel plate. Several holes are opened on the automobile steel plate 1. The opening of the holes is arbitrary without damaging the main structure. At the same time, the thickness of the steel plate can be increased while opening the holes to improve strength.

[0013] Plastic fillers 2 or rubber fillers can be filled in the holes as required, and the plastic fillers are molded by steel plate members before being molded with plastic or rubber, or by simultaneous molding of steel-plastic, steel-rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com