Ground buried type dustbin

A garbage bin and underground buried technology, applied in the field of hidden underground garbage bins, can solve the problems of garbage splashing, time-consuming and labor-intensive, and safety hazards of sanitation workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

[0018] Further explanation will be given below in conjunction with the accompanying drawings

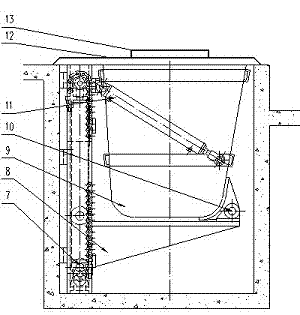

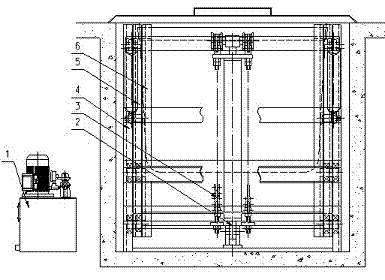

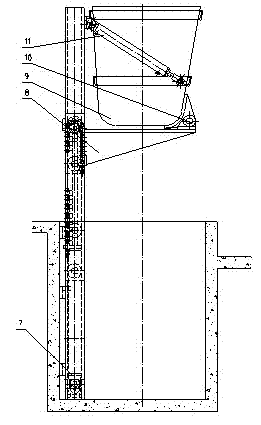

[0019] The hydraulic station 1 is placed in the pit, the lower guide rail 4 and the lifting cylinder 2 are fixed on the pit, the middle guide rail 5 is installed on the inner side of the lower guide rail 4 through the guide wheel 7, the upper guide rail 6 is installed on the inner side of the middle guide rail 5 through the guide wheel 7, and the bracket 8 is installed on the upper guide rail 6, and the rubbish bin is installed on the bracket 8 through the rotating shaft 10 to dump the oil cylinder 11, the cover 12 is installed on the pit, and the feeding port 13 is installed on the cover 12. Lifting oil cylinder 11 is a group, wherein one end is placed on the bracket 8, and the other end is placed in the middle of dustbin 9. The hydraulic station 1 can also be controlled by the hydraulic transmission of the garbage truck, and the garbage truck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com