Hopper of elevator

A hoist and hopper technology, applied in the field of hoppers, can solve the problems of reduced production efficiency, damage to transmission parts, wear and tear of moving parts such as chains and gears, and achieve the effect of improving production efficiency and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

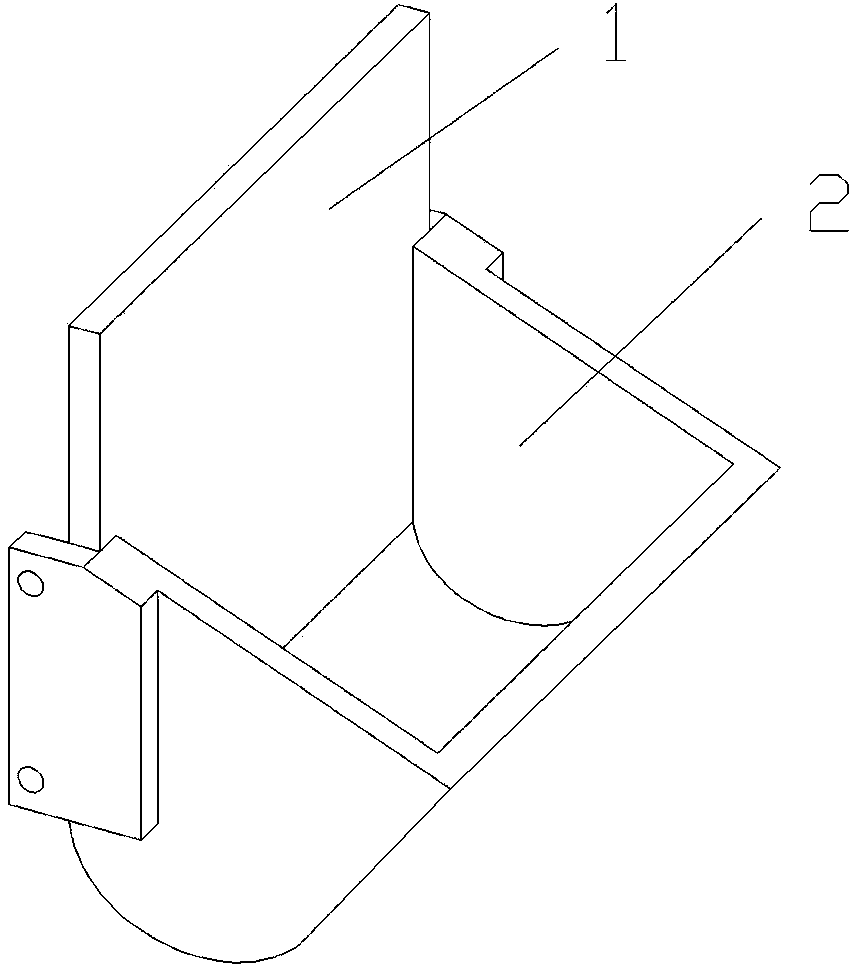

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but does not constitute any limitation to the present invention. figure 1 As shown, the present invention includes a hopper body, and the hopper body is composed of a back plate 1 and a side plate 2, and the back plate 1 is higher than the side plate 2 of the hopper body. Since the hopper body of the present invention adopts the structure that the backboard 1 is higher than the sideboard 2, the backboard 1 can more effectively block more materials flowing in the direction of the backboard 1, making it difficult to splash out of the hopper. Through mass production experiments, it was found that the chains, gears and the outer surface of the hopper body of the hoist had no wear phenomenon, and a large number of parts appeared rust spots, which fully demonstrated that the present invention greatly reduces wear and greatly improves production efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com