Multi-stage permeation filtration and purifying device

A technology of filtration and purification, filter layer, applied in water/sewage multi-stage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Convenience and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

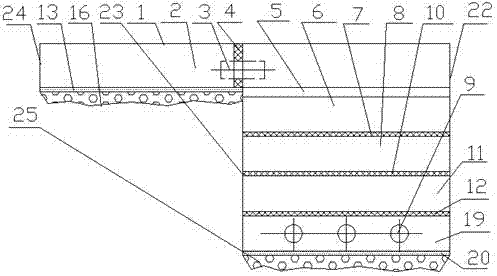

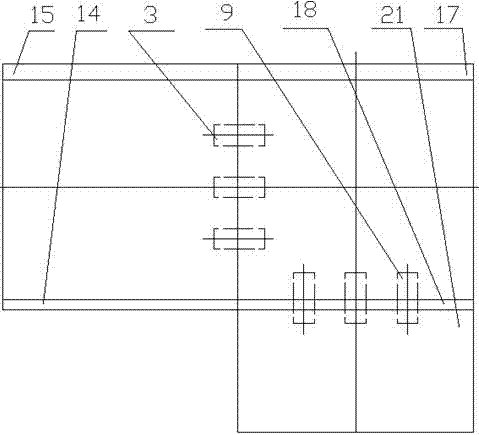

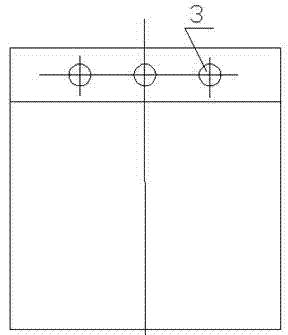

[0023] Embodiment 1, a kind of multi-stage osmotic filtration purifying device, comprises primary filter layer, the first mud layer, the first channel, coarse filter screen, multiple filter layer, the first filter layer, the first filter screen, the second filter layer, The second channel, the second filter screen, the third filter layer, the third filter screen, the first bottom plate, the first isolation plate, the second isolation plate, the third isolation plate, the fourth isolation plate, the fourth filter layer, the second The bottom plate, the settling tank, the first side wall board, the second side wall board, the third side wall board, and the third mud layer are characterized in that the first isolation plate (14), the second isolation plate (15) and the third side A first base plate (13) is sandwiched between the wall plate (24) and the coarse filter screen (4), and the first base plate (13) is above the first mud layer (2) of the primary filter layer (1). The th...

Embodiment 2

[0025] Embodiment 2, with reference to Embodiment 1, the present invention is installed at the sewage outlet, and the primary filter layer (1) and the secondary filter layer (5) are arranged at a position slightly lower than the sewage discharge port, and the primary filter layer (1) is filtered by soil , the multiple filter layer (5) is filtered by sand and gravel. The secondary filter layer (5) is provided with multiple layers, with coarse gravel on the top, medium gravel on the bottom, fine gravel on the bottom, coarse sand, medium sand, and fine sand on the bottom. There are multiple layers to allow sewage from the primary filter Layer (1) is discharged to sedimentation tank (21) by the second channel (9) after being filtered to double filter layer (5), also can directly lead into drainage channel and enter pond reservoir.

Embodiment 3

[0026] Embodiment 3, with reference to Embodiment 1, on the primary filter layer (1) there is a filtrate, which can be filter particles, filter powder, or coarse-pore foam. The installation structures of the primary filter layer (1) and the secondary filter layer (5) remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com