A kind of production method of long-acting antibacterial polypropylene special material

A technology of antibacterial polypropylene and a production method, which is applied in the field of producing long-acting antibacterial polypropylene special materials, can solve the problems of poor color stability of silver-based antibacterial agents, inability to uniformly disperse antibacterial components, and inability to lasting antibacterial effects, and achieve physical and mechanical properties. and long-term antibacterial performance improvement, quick and easy switching, less transition products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

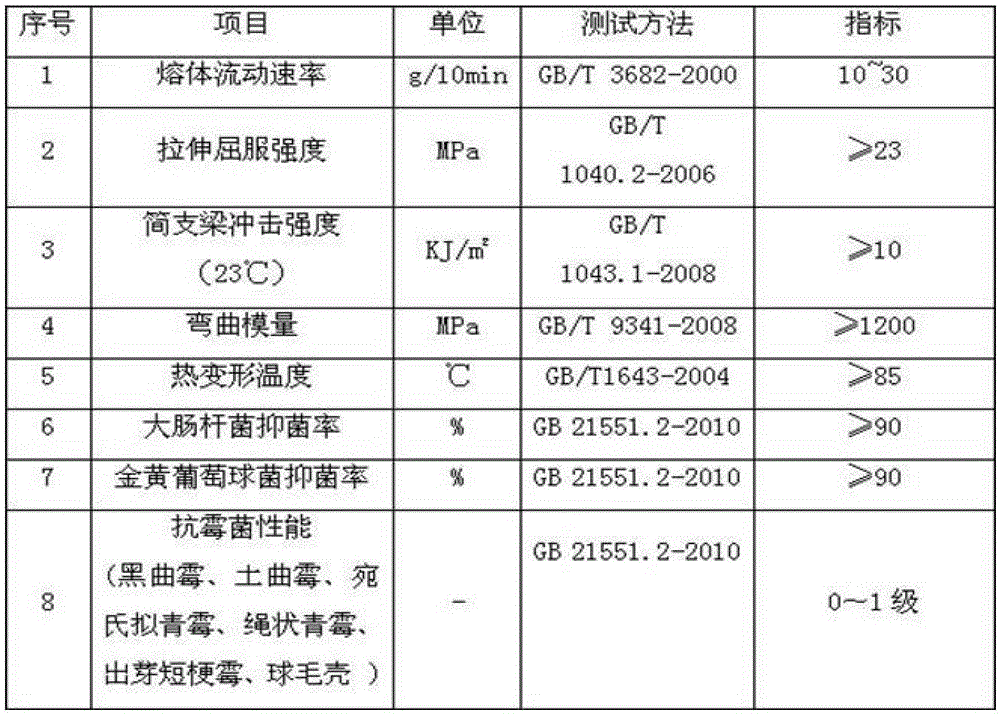

Examples

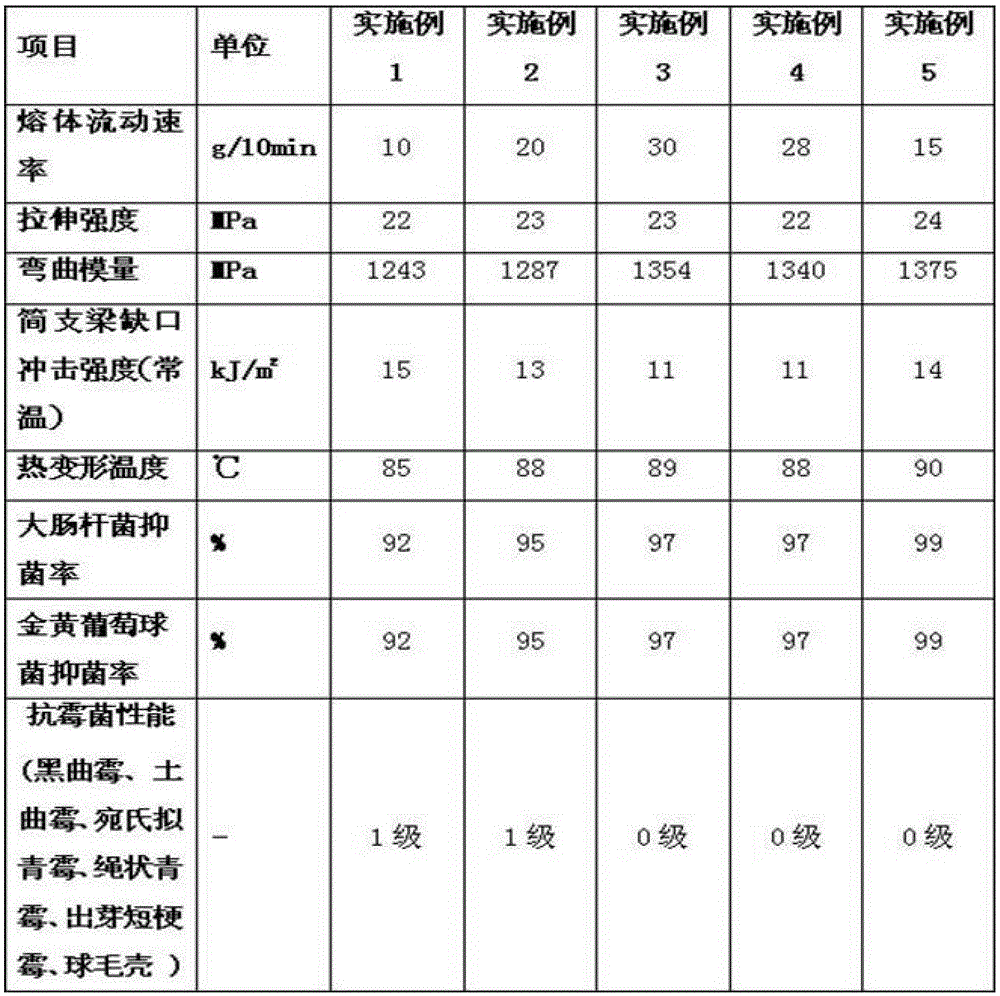

Embodiment 1

[0018] After prepolymerizing the catalyst TK and some polypropylene monomers, add the cocatalyst triethylaluminum, external electron donor dimethyldimethoxysilane, propylene monomer and hydrogen into the first reactor, and the reaction temperature is 65°C , reaction pressure 2~3MPa, H 2 / C 3 The mass ratio is controlled at 0.15‰, and the gas phase polymerization is carried out. The reaction product enters the second reactor, and the comonomer ethylene is added, the amount of which is controlled at 1.8Kg / hr, the reaction temperature is 75°C, the reaction pressure is 2-3MPa, and the ethylene content in the polymer is controlled at 7.5%. In the granulation process, the reaction product is added with 0.3% of the nano-rubber compounding auxiliary system loaded with antibacterial agent, and the long-acting antibacterial polypropylene special material is obtained from the discharge.

Embodiment 2

[0020] After the catalyst ND is pre-complexed with the cocatalyst triethylaluminum, the external electron donor (combined with dimethyldimethoxysilane and tetraethoxysilane), propylene monomer, and hydrogen are added to the first reactor , reaction temperature 70°C, reaction pressure 2-3MPa, H 2 / C 3 The mass ratio is controlled at 0.1‰, and the gas phase polymerization is carried out. The reaction product enters the second reactor, and the comonomer ethylene is added, the amount of which is controlled at 1.5Kg / hr, the reaction temperature is 80°C, the reaction pressure is 2-3MPa, and the ethylene content in the polymer is controlled at 7.0%. In the granulation process, the reaction product is added with 0.4% of the nano-rubber compounding auxiliary system loaded with antibacterial agent, and the long-acting antibacterial polypropylene special material is obtained from the discharge.

Embodiment 3

[0022] The catalysts CDI and NG are compounded first, and then pre-polymerized with some polypropylene monomers, and then compounded with cocatalyst triethylaluminum and external electron donors (dimethyldimethoxysilane and tetraethoxysilane ), propylene monomer and hydrogen are added to the first reactor, the reaction temperature is 60°C, the reaction pressure is 2-3MPa, H 2 / C 3 The mass ratio is controlled at 0.2‰, and the gas phase polymerization is carried out. The reaction product then enters the second reactor, and the comonomer ethylene is added, the amount of which is controlled at 2.0Kg / hr, the reaction temperature is 75°C, the reaction pressure is 2-3MPa, and the ethylene content in the polymer is controlled at 7.5%. In the granulation process, the reaction product is added with 0.5% of the nano-rubber compounding auxiliary system loaded with antibacterial agent, and the long-acting antibacterial polypropylene special material is obtained from the discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com