A wind turbine blade with tiplets

A wind turbine blade and blade tip technology, applied in the energy field, can solve problems such as high pressure, loss of blade tip, and no lift generated by the blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] The core idea of this application:

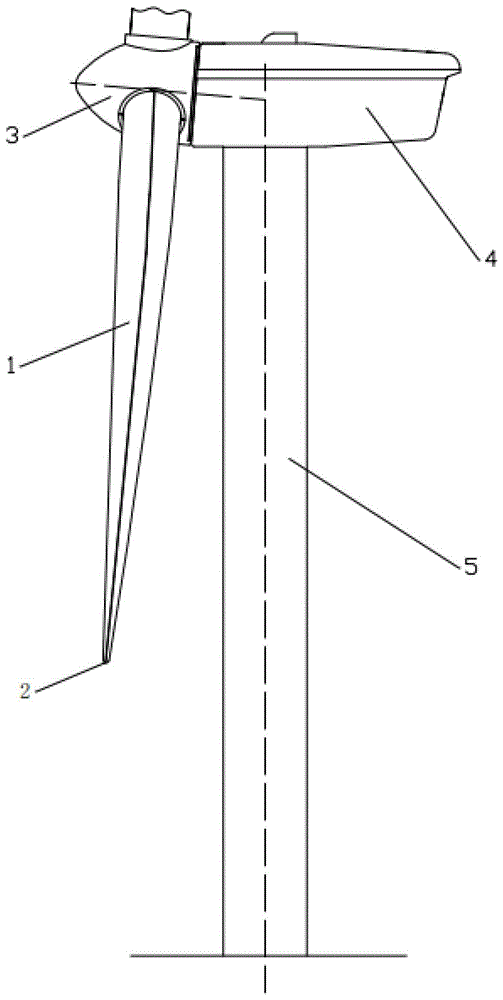

[0034] Such as figure 1 As shown, the horizontal axis wind turbine in the prior art includes: a blade 1 , a blade tip 2 , a hub 3 , a nacelle 4 and a tower 5 . When the blade 1 rotates, a wake flow field will be generated at the tip of the blade 1 along with the rotation of the blade 1 . This wake field has vortices exhibiting multiple helical structures. When the vortex flows around the blade tip, there will be a pressure difference between the upper and lower surfaces of the blade tip section, causing the vortex to flow around the blade tip, which means that the circulation at the blade tip is reduced, resulting in a decrease in torque, making The blades do not generate lift, this los...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com