Piezoelectric type brake executing mechanism of electronic mechanical brake system of vehicle

An electromechanical braking and actuator technology, applied in the direction of brake actuators, mechanical equipment, gear transmission mechanisms, etc., can solve the problems of complex structure of electromechanical brake actuators and affect the working performance of EMB system, and improve dynamic performance. Response performance and braking performance, high dynamic response performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

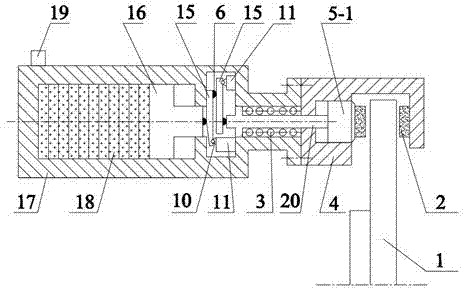

[0018] Such as figure 1 As shown, a piezoelectric brake actuator of a vehicle electromechanical brake system includes a brake caliper body 4, a housing 17, a piston 16, a brake piston assembly 5, a return spring 3, a displacement amplification mechanism, a piezoelectric The element 18 and the friction block 2 respectively located on both sides of the brake disc 1 of the vehicle and cooperating with the brake disc 1 for braking, the brake piston assembly 5 is slidably installed on the brake caliper body 4, the piston 16 and the piezoelectric element 18 is located in the housing 17, one side of the piston 16 is in contact with the piezoelectric element 18, and the displacement amplification mechanism is arranged between the other side of the piston 16 and the brake piston assembly 5 so that when the piezoelectric element 18 applies an external electric field to generate When the mechanical deformation in the axial direction of the piston 16 forms an axial displacement in this di...

Embodiment 2

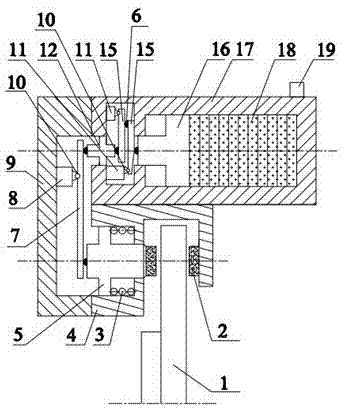

[0028] Such as figure 2 As shown, a piezoelectric brake actuator of a vehicle electromechanical brake system includes a brake caliper body 4, a housing 17, a piston 16, a brake piston assembly 5, a return spring 3, a displacement amplification mechanism, a piezoelectric The element 18 and the friction block 2 respectively located on both sides of the brake disc 1 of the vehicle and cooperating with the brake disc 1 for braking, the brake piston assembly 5 is slidably installed on the brake caliper body 4, the piston 16 and the piezoelectric element 18 is located in the housing 17, one side of the piston 16 abuts against the piezoelectric element 18, and the displacement amplifying mechanism is arranged between the other side of the piston 16 and the brake piston assembly 5 so that when the piezoelectric element 18 is applied external The electric field produces mechanical deformation in the axial direction of the piston 16 to form an axial displacement in this direction. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com