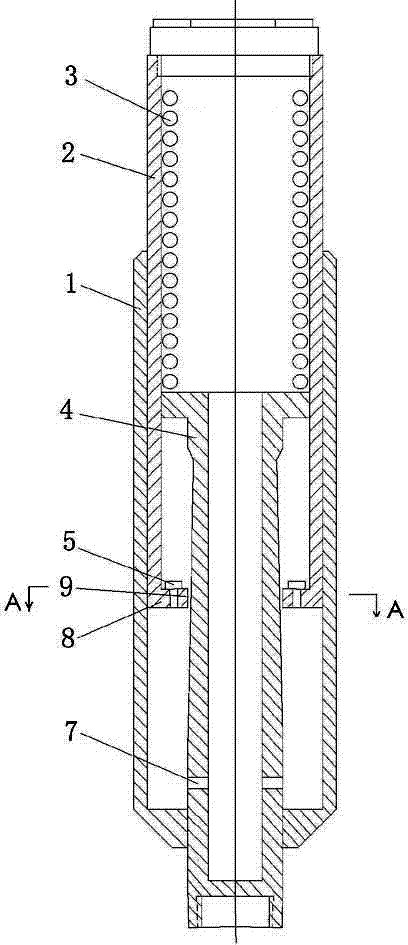

Automatic variable damping front shock absorber of motorcycle capable of vibrating along with ups and downs of road surface

A motorcycle and variable damping technology, which is applied to shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problem of not considering the influence of the change rate of the cross-sectional area of the shock absorber spring pressure and load orifice , to achieve the effect of ensuring comfort and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

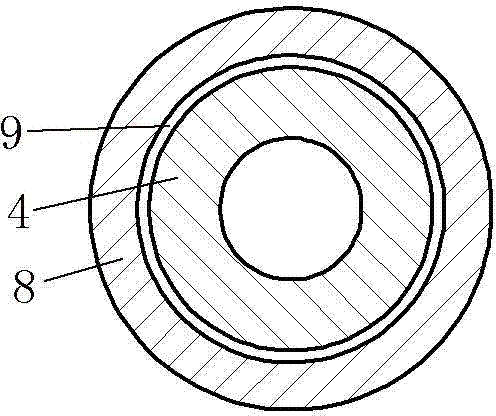

Method used

Image

Examples

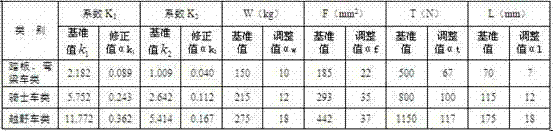

Embodiment 1

[0029] A pedal motorcycle, the design motorcycle and load weight W is 170kg, and the piston area F is 200mm 2 , The spring pressure and load T is 600N, and the piston stroke L is 60mm. Compared with the reference value of scooter motorcycles in the above table, the design values of W and F are larger than the reference value, and the design value of L is smaller than the reference value. Positive number; if the design value of T is greater than the reference value, take a negative number; then:

[0030] = + =2.182+0.089 =2.415 (N·mm / kg)

[0031] = + =5.414+0.167 =5.554 (N·mm / kg)

[0032] = = 1.915 (mm 2 )

[0033] = = 0.883 (mm 2 )

[0034] = =0.0172 (mm 2 / mm).

Embodiment 2

[0036] An off-road vehicle motorcycle, the design motorcycle and load weight W is 310kg, and the piston area F is 500mm 2 1. The spring pressure and load T is 1300, and the piston stroke L is 200mm. Compared with the reference value of off-road motorcycles in the above table, the design values of W and F are larger than the reference value, and take a positive number; the ratio of T and L design values If the base value is large, take a negative number; then:

[0037] = + =11.772+0.362 =12.076 (N·mm / kg)

[0038] = + =3.705+0.103 =3.891;

[0039] = =7.294 (mm 2 )

[0040] = =2.350 (mm 2 )

[0041] = =0.0247 (mm 2 / mm).

[0042] Obviously, the beneficial technical effect of the present invention is to accurately set the maximum cross-sectional area of the throttle hole, the minimum cross-sectional area of the throttle hole and the throttle The rate of change of the cross-sectional area of the orifice ensures the comfort and safety of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com