Commercial oven hearth

A technology for commercial stoves and hearths, applied in household stoves, household stoves/stoves, applications, etc., can solve the problems of not meeting aesthetic requirements, poor surface finish, low heat utilization rate, etc., to achieve improved appearance, aesthetics, The effect of improving the utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] Example one

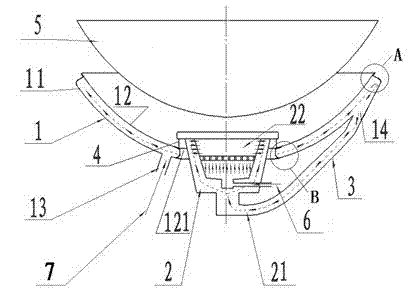

[0023] Contrast figure 1 , The furnace of the commercial stove of the present invention includes a furnace wall 1, a burner 2 and a hot air pipe 3. The burner 3 is placed in the center of the bottom of the furnace wall 1. The furnace wall 1 is a hollow wall formed by an outer wall 12 and an inner wall 11 made of glass-ceramics; the outer wall 11 is provided with an air inlet 13 and an air outlet 14, hot air The pipe 3 connects the air outlet 14 and the air inlet 21 at the lower end of the burner, and guides the hot air gas discharged from the air outlet 12 to the burner 2.

[0024] The inner wall 12 made of crystallized glass is in the shape of a pot, and the bottom is provided with a burner hole 121 through which the burner passes. The outer wall 11 is a ferrule adapted to the shape of the inner wall, and is sleeved on the outside of the inner wall 12. The outer wall 11 can be made of metal or ceramic material, and the metal material is generally a thin...

Example Embodiment

[0028] Example two

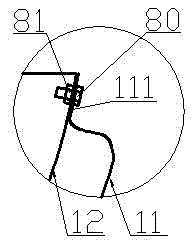

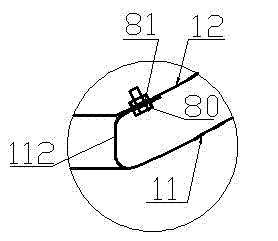

[0029] The furnace of the commercial stove of the present invention can also be designed as Figure 4 The structure includes the furnace wall 1 and the burner 2, the hot air pipe 3 and the heat-absorbing air pipe 9 placed in the center of the furnace bottom. The furnace wall 1 is made of glass-ceramic, and the heat-absorbing air pipe is tightly wound along the outside of the furnace. On the furnace wall 1, the air outlet 82 of the heat absorption air pipe 4 is connected to the air inlet at the lower end of the burner through the hot air pipe 3, and the heated air in the heat absorption air pipe is introduced to the burner.

[0030] Further, the heat absorption air duct 9 is made of a material with good thermal conductivity, such as stainless steel. The heat-absorbing air pipe 9 is tightly spirally wound on the furnace wall 1, and its air inlet end 91 and air outlet end 92 are respectively arranged at the bottom and upper part of the opposite furnace wall. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com