Intelligent sensor for train wheels

A technology of intelligent sensors and train wheels, which is applied in the direction of transmitting sensing components, instruments, scientific instruments, etc. by using electric/magnetic devices, can solve problems such as short trouble-free working time, low reliability of sensors, and inconvenient installation and maintenance. Avoid damage to the sensor caused by lightning and high-voltage induction, easy installation and maintenance, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

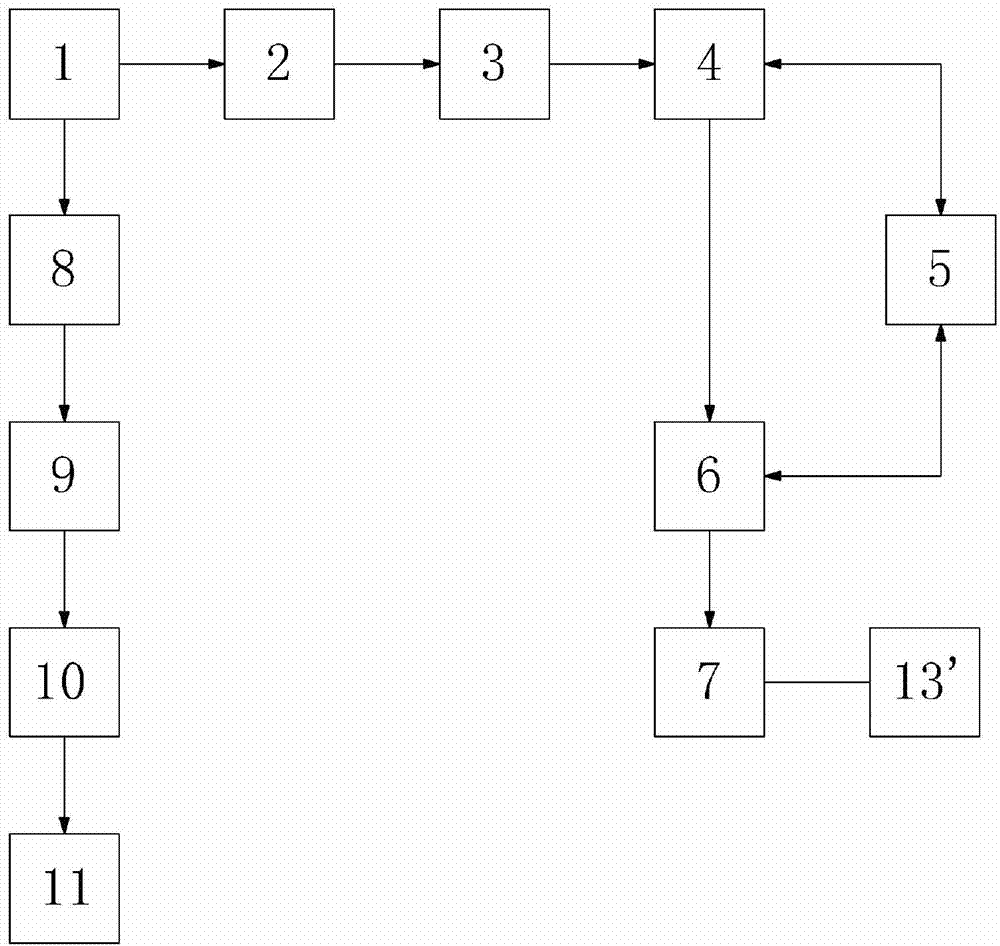

[0026] figure 1 Shown, a kind of specific embodiment of the present invention is, a kind of train wheel intelligent sensor, and its composition is:

[0027] The permanent magnet coil 1 is sequentially connected with the low-pass filter circuit 2, the amplification and shaping circuit 3, the analog / digital conversion circuit 4, the output interface and the interface conversion circuit 6; the analog / digital conversion circuit 4, the output interface and the interface conversion circuit 6 are all the same as the micro The processing control unit 5 is connected;

[0028] The permanent magnet coil 1 is also connected to the rectification filter circuit 8, the energy storage circuit 9, the charging control circuit 10, and the rechargeable battery 11 in sequence; The processing control unit 5, the output interface and the interface conversion circuit 6 supply power.

[0029] The output interface and the interface conversion circuit 6 of this example are also connected to the wirele...

Embodiment 2

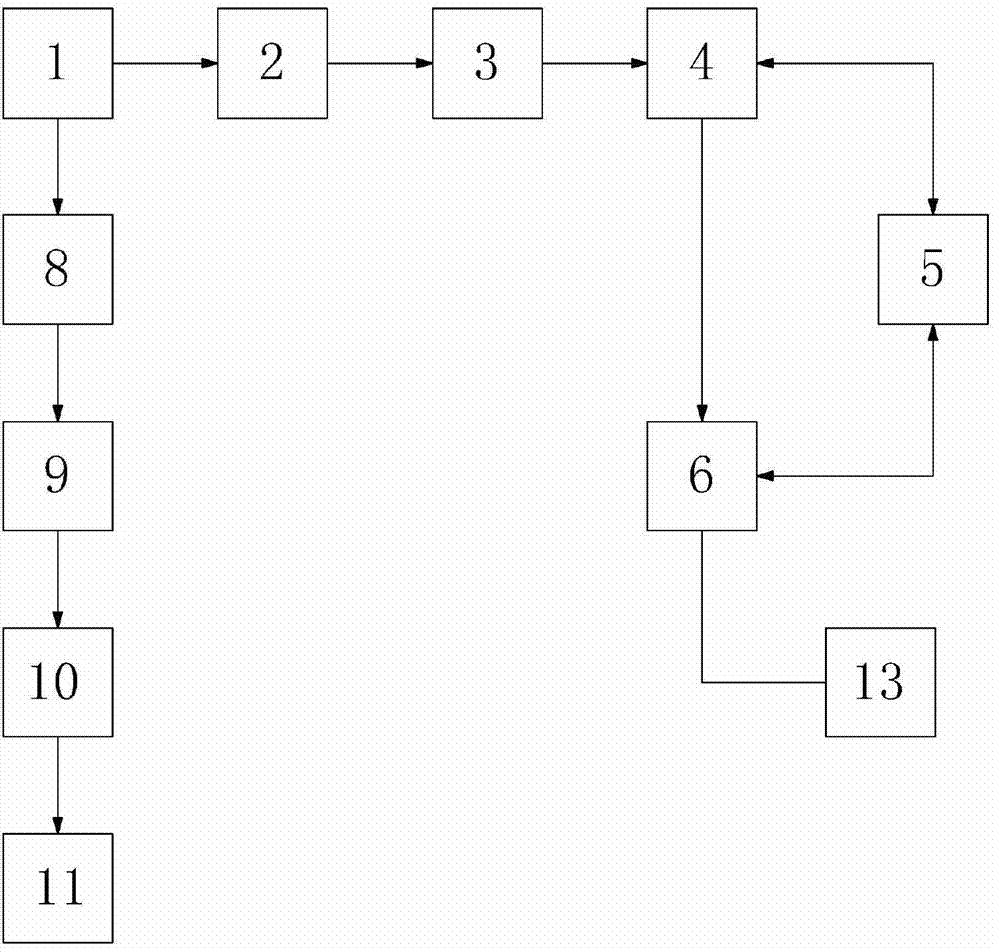

[0034] figure 2 Shown, another kind of embodiment of the present invention is, a kind of train wheel intelligent sensor, and its composition is:

[0035] The permanent magnet coil 1 is sequentially connected with the low-pass filter circuit 2, the amplification and shaping circuit 3, the analog / digital conversion circuit 4, the output interface and the interface conversion circuit 6; the analog / digital conversion circuit 4, the output interface and the interface conversion circuit 6 are all the same as the micro The processing control unit 5 is connected;

[0036] The permanent magnet coil 1 is also connected to the rectification filter circuit 8, the energy storage circuit 9, the charging control circuit 10, and the rechargeable battery 11 in sequence; The processing control unit 5, the output interface and the interface conversion circuit 6 supply power.

[0037] The output interface and the interface conversion circuit 6 of this example are also connected to the lightnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com