Passive containment spraying-submerged cooling system

A passive containment and cooling system technology, applied in the field of special safety systems for nuclear reactors, can solve the problems of unfavorable earthquake resistance of shielded workshops, high construction cost and maintenance cost, improve safety and economy, low construction cost and maintenance cost, system simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

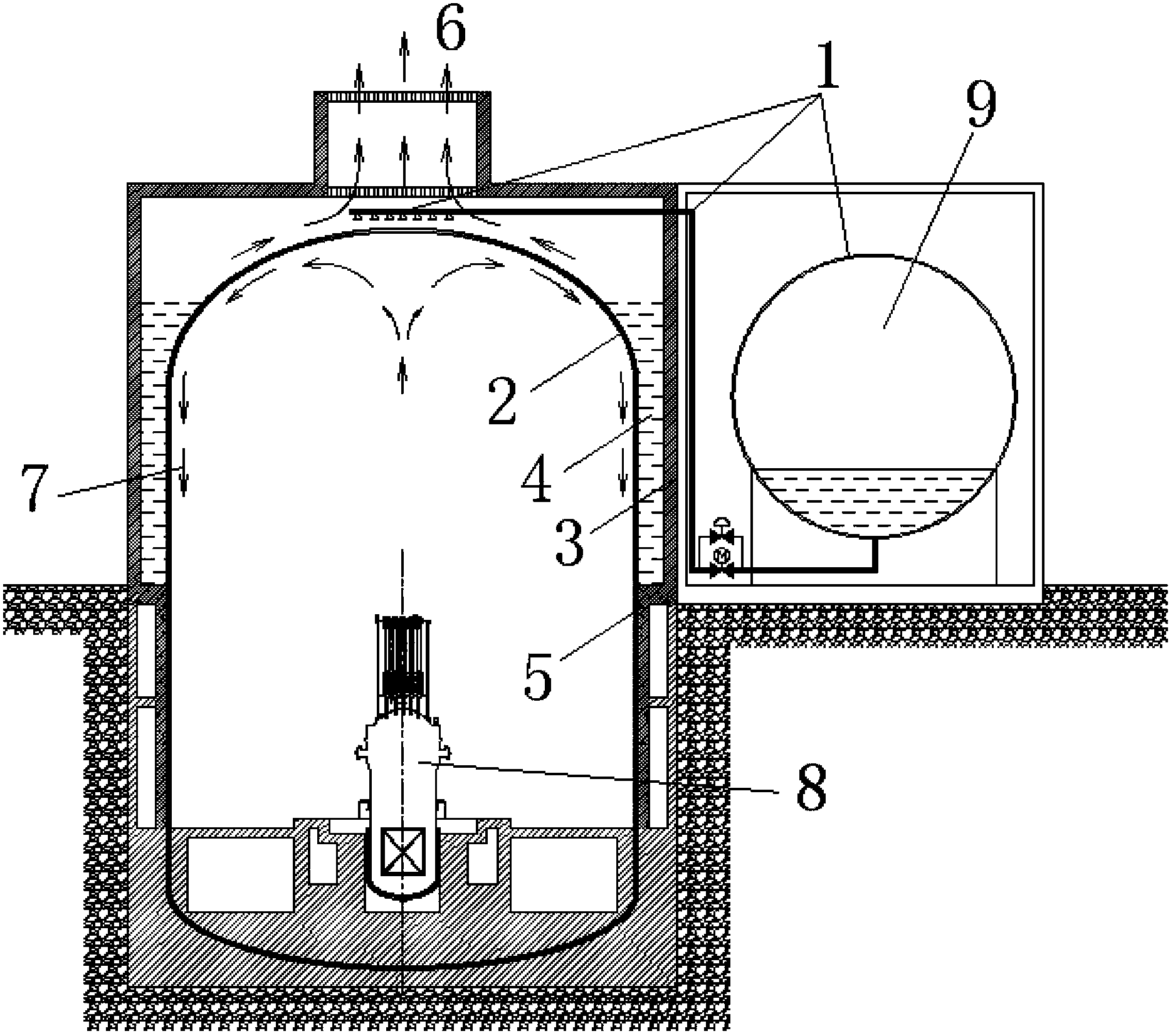

[0010] like figure 1 As shown, a passive containment spray-submersion cooling system includes a reinforced concrete shielded factory building 3, a containment vessel 2 is arranged in the reinforced concrete shielded factory building 3, and the containment vessel 2 and the reinforced concrete shielded factory building 3 are attached below the ground level together form a steel-concrete composite structure 5, a passive containment sprinkler 1 is installed above the containment 2, a reactor 8 is installed inside the containment 2, and a steam outlet 6 is opened on the top of the reinforced concrete shielding plant 3 for safety The shell 2, the reinforced concrete shielding factory building 3 and the steel-concrete composite structure 5 form a water-tight annular space 4 above the ground level. When the spray submerged water in the water-tight an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com