Artificial lung

An artificial lung, hollow technology, applied in the field of artificial lung, can solve the problems of reducing gas exchange performance, reducing blood filling volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

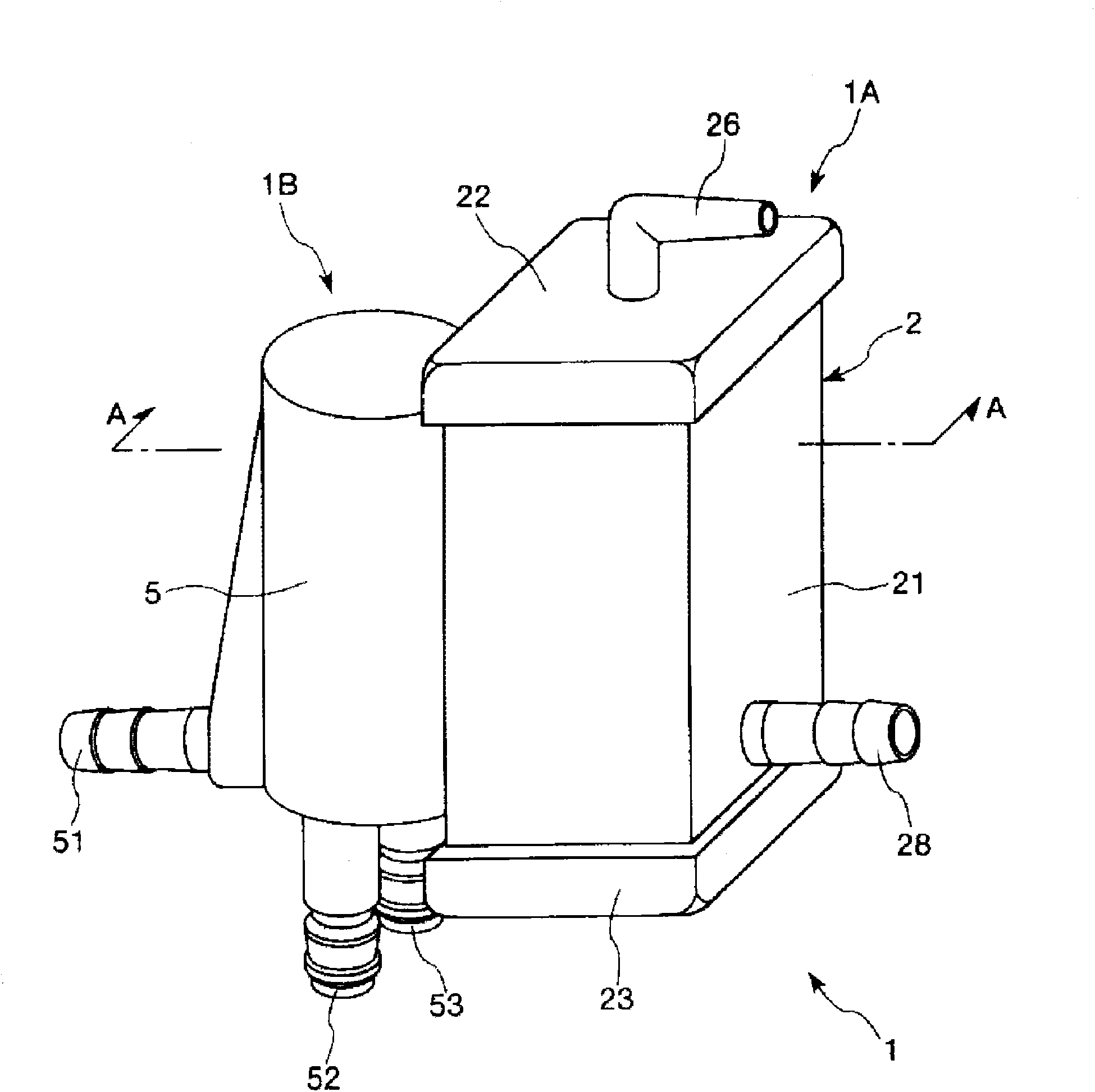

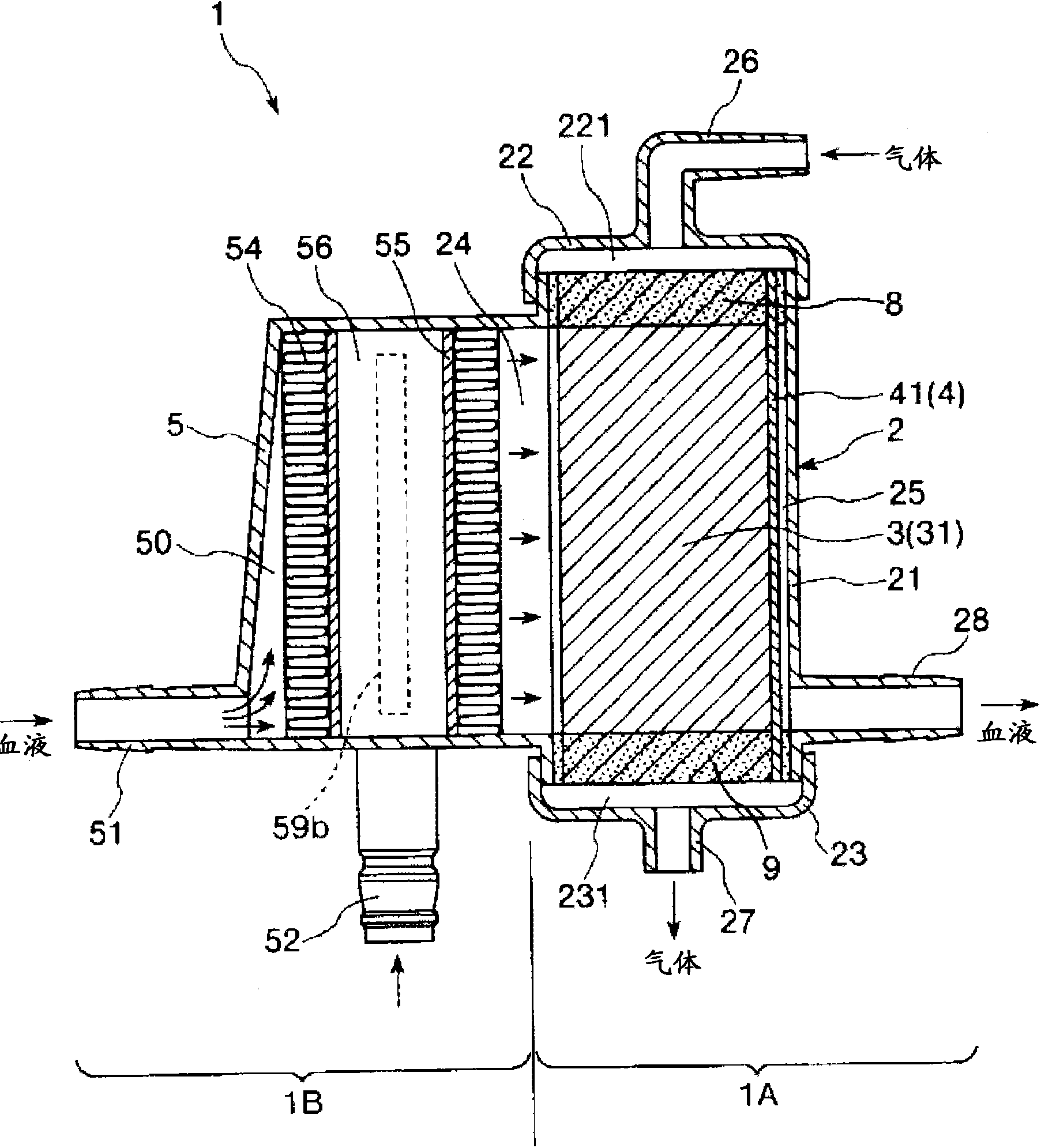

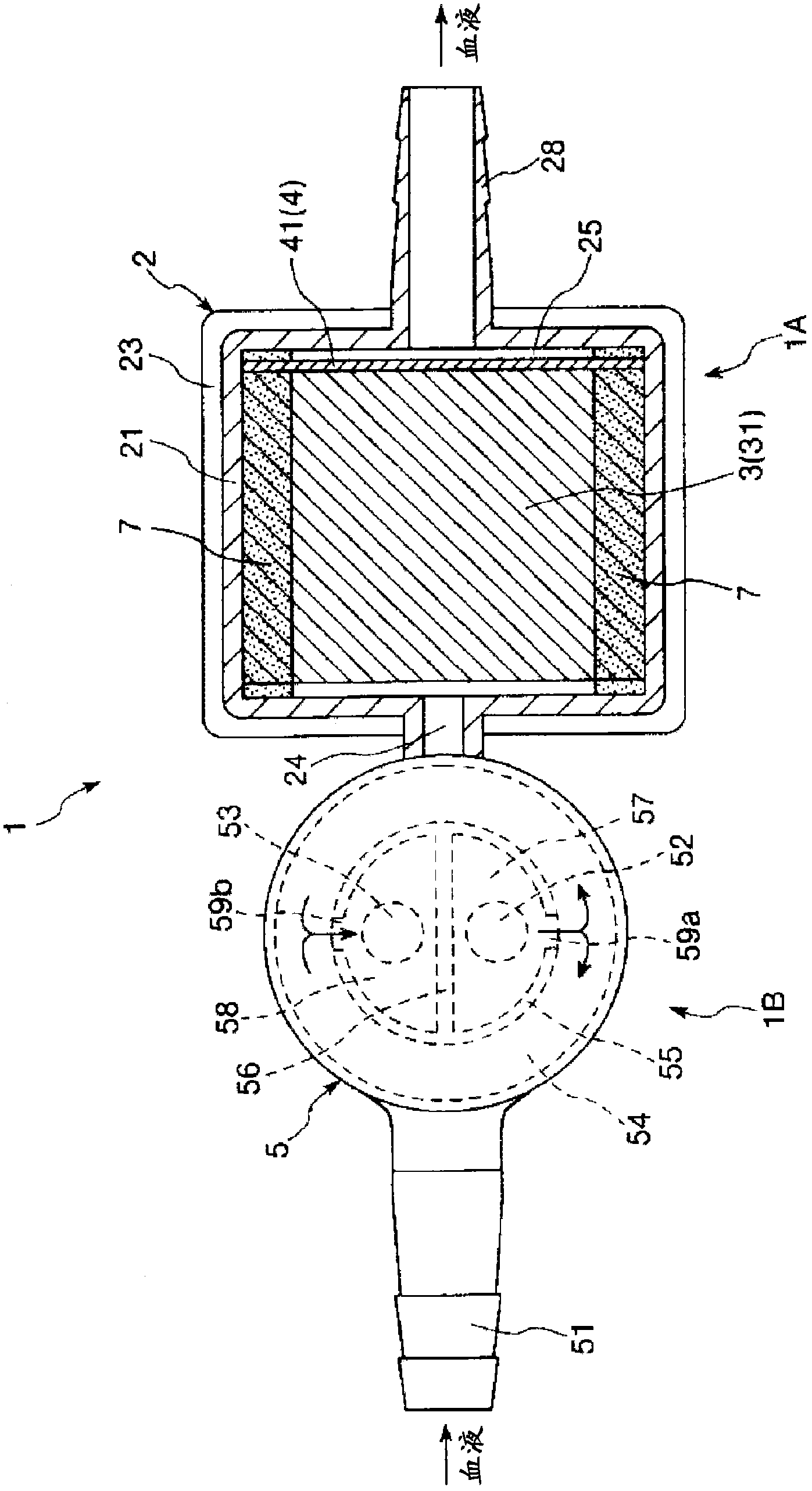

[0038] figure 1 It is a perspective view showing the first embodiment of the artificial lung of the present invention, figure 2 for figure 1 A-A line sectional view in, image 3 for figure 1 A cross-sectional view of the artificial lung in the shown artificial lung, Figure 4 for figure 2 The enlarged cross-sectional view of the lower right part (hollow fiber membrane layer and filter element) in . Figure 5 for schematic representation figure 1 Perspective view of the hollow fiber membrane layer and septum of the artificial lung shown. Figure 6 to represent figure 1 Perspective view of the hollow fiber membrane shown. It should be noted that the figure 1 and figure 2 The upper side is referred to as "upper" or "upper", the lower side is referred to as "lower" or "below", the left side is referred to as "blood inflow side" or "upstream side", and the right side is referred to as "blood outflow side" or "downstream side". "Be explained.

[0039] Figure 1 to Fi...

no. 2 Embodiment approach

[0120] Figure 7 It is a plan view showing a second embodiment of the artificial lung of the present invention, Figure 8 For viewing from the arrow B side Figure 7 The diagram of the artificial lung shown, Figure 9 for Figure 6 The C-C line sectional view in, Figure 10 for from Figure 8 In the diagram observed on the arrow D side, Figure 11 for Figure 7 E-E line sectional view in, Figure 11 for Figure 7 The F-F line sectional view in . It should be noted that the Figure 7 , Figure 9 and Figure 10 The left side in is called "left" or "left", and the right side is called "right" or "right". in addition, Figure 7 ~ Figure 12 In the description, the inner side of the artificial lung is referred to as the "blood inflow side" or "upstream side", and the outer side is referred to as the "blood outflow side" or "downstream side".

[0121] Hereinafter, a second embodiment of the artificial lung of the present invention will be described with reference to the...

Embodiment 1

[0169] manufacture Figure 7 ~ Figure 12 The artificial lung shown. As a constituent material of each hollow fiber membrane of the hollow fiber membrane layer, polypropylene is used. In addition, the dimensions of the hollow fiber membranes are as follows.

[0170] Average spacing distance ε: 60μm

[0171] Outer diameter OD: 200μm

[0172] OD / ε: 3.3

[0173] Inner diameter ID: 140μm

[0174] Effective length L: 170mm

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com