Two-pass automatic-spraying track optimization method of complex curved surfaces

A complex curved surface, automatic spraying technology, applied in spraying devices, special data processing applications, instruments, etc., can solve the problem of not being able to obtain coating quality and two spraying tracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

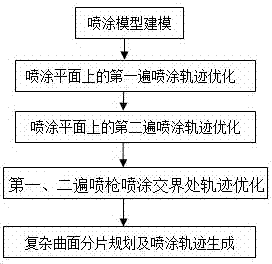

[0064] like figure 1 , figure 2 and image 3 As shown, the present invention has designed a kind of two-pass automatic spraying trajectory optimization method for complex curved surfaces, comprising the following steps:

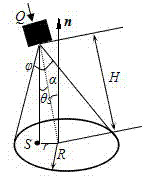

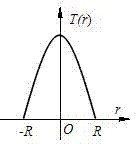

[0065] Step 001. Use the experimental method to model the spraying process of the spray gun, and obtain the coating thickness distribution model of the spray gun for the spraying plane, as follows;

[0066] During the spraying process, the coating growth rate model formed by the spray gun directly affects the quality of the entire coating production, so it is very important. The present invention is developed based on a conical paint spray gun whose spray torch has a circular cross-section and the same coverage in all directions. Assuming that the spraying distance H, spraying flow rate Q, spraying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com