Film-forming agent for seed clothing sheet and preparation method thereof

A film-forming agent and coating technology, which is applied in the field of film-forming agent for seed coating and its preparation, can solve the problems of poor film wear resistance, easy flake off, low seed germination rate, etc., and achieve the goal of coating High uniformity, healthy growth protection, and low coating shedding rate

Inactive Publication Date: 2010-12-01

CHINA AGRI UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This kind of material generally takes a long time to form a film, and the formed film is easy to fall off in water, and the slow release control ability is poor.

Oil-soluble high molecular polymers need to use organic solvents and have disadvantages such as poor air permeability and low seed germination rate

The characteristics of the polymer itself determine that the film-forming strength of the high-adhesive variety is generally low, the product fluidity is poor, the film-forming is uneven (that is, the leveling performance is poor), the wear resistance of the film is poor, and it is easy to become powdery. Falling off; On the contrary, varieties with high film-forming strength have poor adhesion, poor affinity between the film and seeds, and are easy to fall off in flakes

This caused some early seed coating products to have defects in film-forming properties

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

experiment example 2

experiment example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Login to View More

Abstract

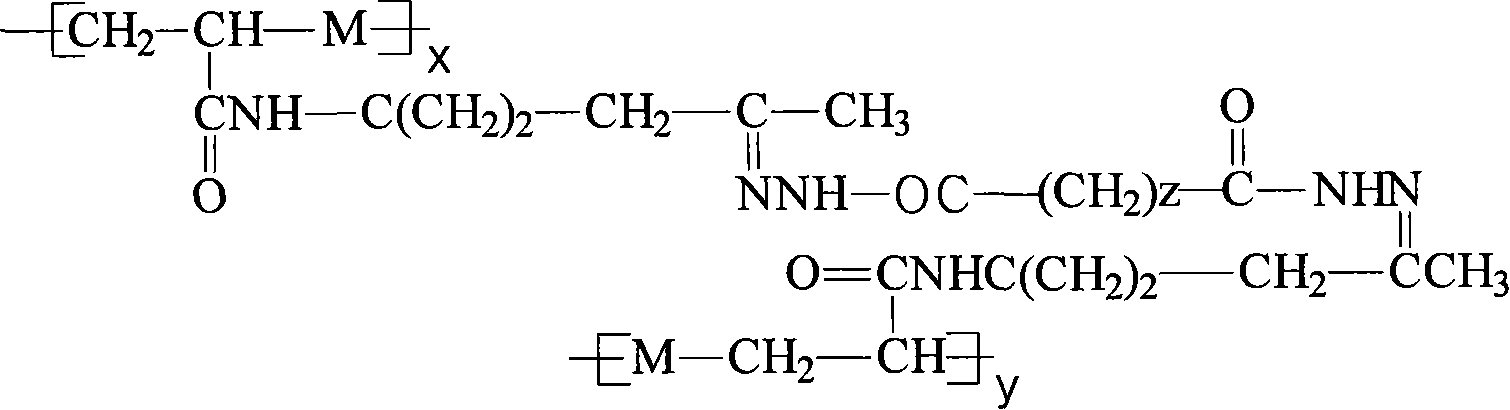

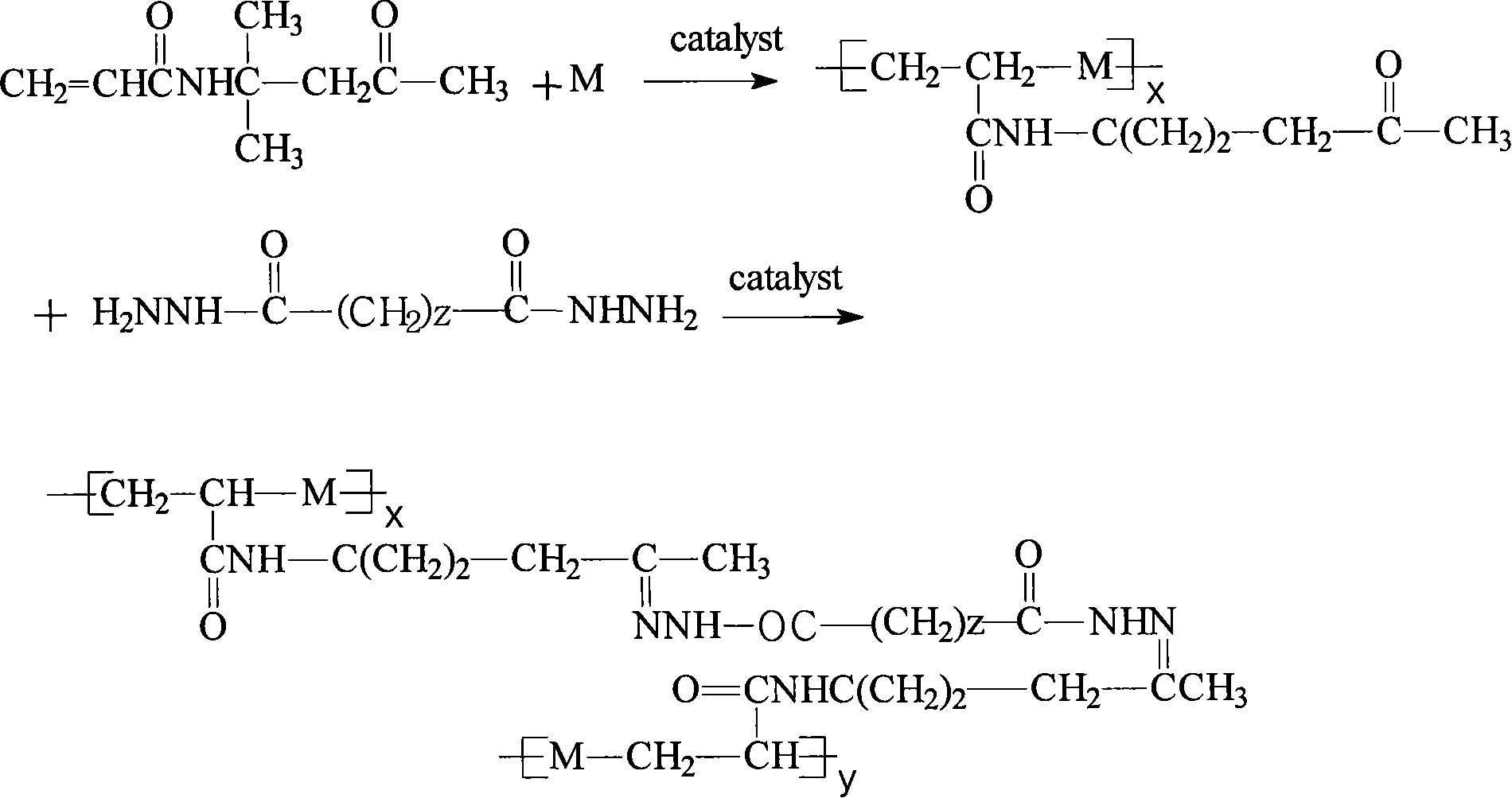

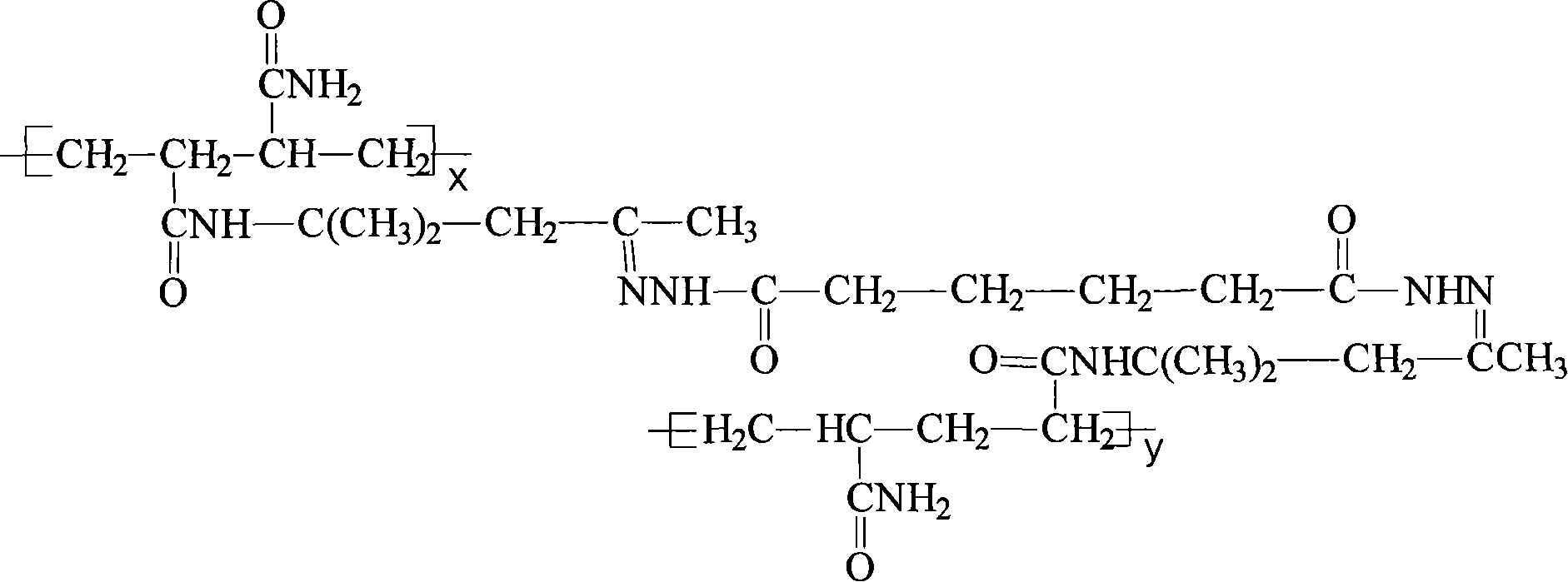

The invention discloses a film former for seed coating and the preparation method thereof. The preparation method comprises the steps as follows: subjecting diacetone acrylamide and unsaturated monomer to copolymerization reaction to obtain polymer, and reacting with dihydrazide compound to obtain film-forming material for seed-coating. The unsaturated monomer compound can be one or more selectedfrom methyl methacrylate, styrene, vinyl acetate, vinyl chloride, maleic anhydride, N-vinyl pyrrolidone, vinylidene chloride, acrylonitrile, methyl vinyl ketone, methacrylic acid, acrylamide, methyl acrylate, ethyl acrylate, butyl acrylate, dihydrazide, N-vinylcarbazole and butadiene. The film former prepared by the method has good film physical chemical properties such as forming property, waterresistance, air permeability, water permeability, etc., and drug slow release function to prolong drug effect and protect healthy growth of crops.

Description

A kind of film-forming agent for seed coating and preparation method thereof technical field The invention relates to a film-forming agent for seed coating and a preparation method thereof. Background technique Film-forming agent is one of the important auxiliaries in pesticide seed coating agents, the key functional component of seed coating and the common component of all seed coating agents. Because the introduction of the film-forming agent enables the seed coating agent to form a film on the surface of the seed, which is different from the seed treatment agent. The main function of the film-forming substance in the seed coating agent is to adhere the active ingredient to the surface of the seed and form a uniform and smooth drug film. On the one hand, the film-forming material has strong water resistance and cannot be dissolved by water in soil with high moisture, especially in paddy fields; on the other hand, it has good water permeability and air permeability, allo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F220/56C08F220/58C08F220/14C08F212/08C08F8/00A01C1/06

Inventor 曹永松李健强刘西莉伍华英石天玉钱坤汤涛

Owner CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com