A continuous dipping machine

A paint dipping machine and paint dipping technology, applied in coatings, devices for coating liquid on the surface, etc., can solve the problems affecting cost, quality and service life, the number of one-time dipping paint parts is small, and the separation of paint dipping machines is not clear, etc. problems, to achieve the effect of improving processing efficiency and yield, reducing energy consumption, and spacious operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

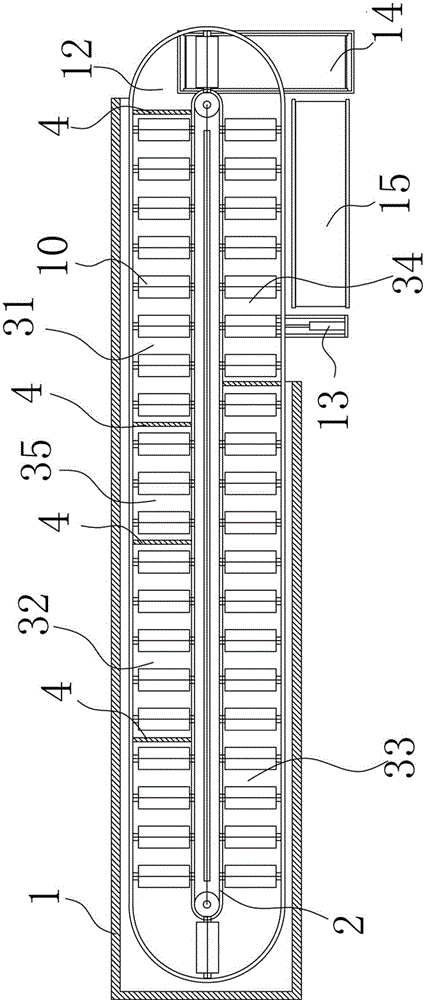

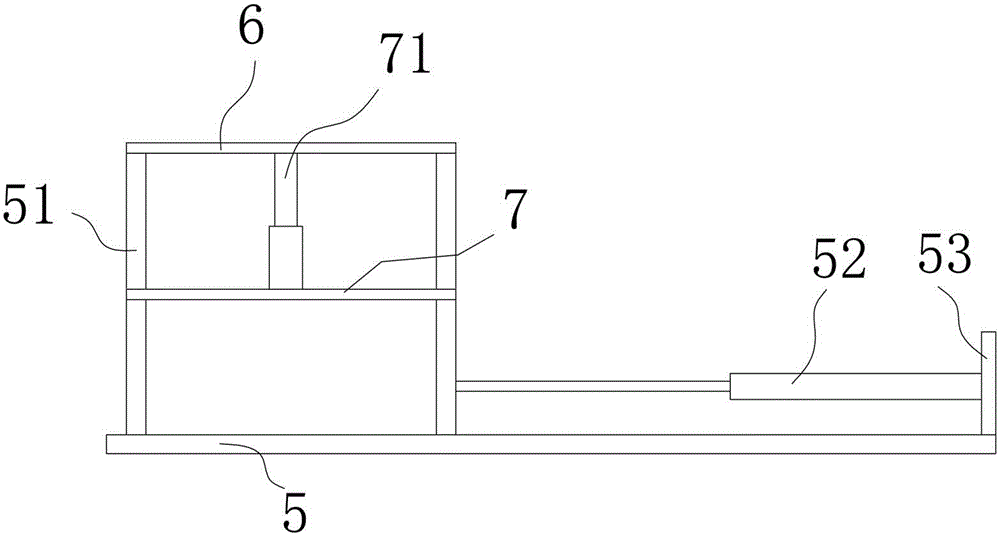

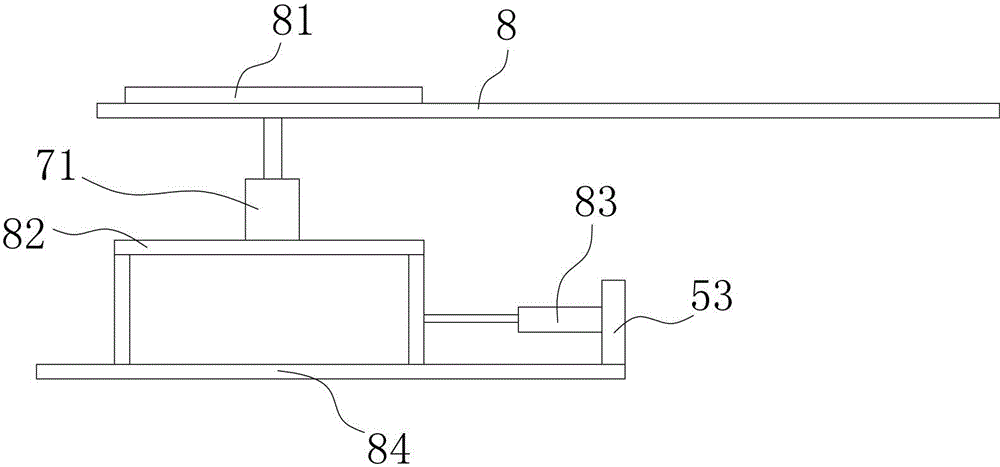

[0043] A continuous paint dipping machine, comprising a chassis 1 and a frame with a horizontal circulation track 12 arranged in the chassis 1. The horizontal circulation track 12 is provided with a rack for loading workpieces to be dipped in a circular transmission on a horizontal plane through a transmission device. Hanging basket 10, the hanging basket 10 is provided with a hanging basket hanging part 11, the hanging basket hanging part 11 is a hook, the transmission device includes a chain 2 for pulling the hanging basket 10, and the chain 2 is provided with a hanging basket hanging part 11 adapted The hanging basket bearing part 21, the hanging basket bearing part 21 is a cross bar erected on the horizontal circulating track 12, and the hook opening faces the moving direction of the hanging basket 10 on the horizontal circulating track 12 and is buckled into the cross bar; the frame can be opened and closed through The partition door 4 is divided into a pre-baking area 31, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com