Pipe clamp stretching mold

A technology for drawing dies and pipe clamps, which is applied in the field of pipe clamp drawing dies, can solve problems such as uneven distribution of blank-holding force, uneven marks on the surface of pipe clamps, and insufficient stability of blank-holding force, so as to improve rationality and stability , good fluidity and stable blank holder force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described below in conjunction with specific embodiment:

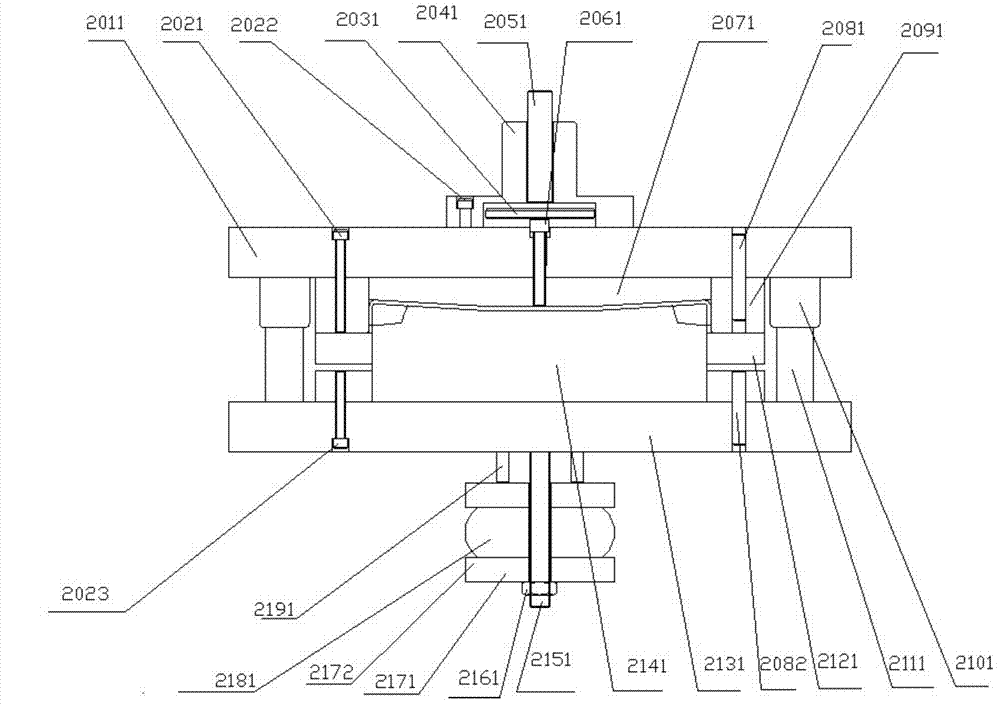

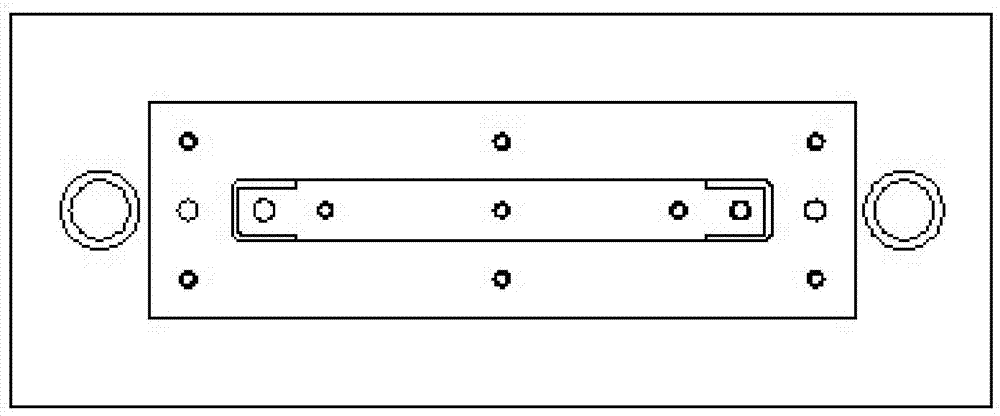

[0018] A pipe clamp stretching die, comprising an upper template 2011, screw I 2021, screw II 2022, a beating plate 2031, a mold handle 2041, a beating rod 2051, a beating nail 2061, a beating block 2071, a pin I 2081, a die 2091, Guide sleeve 2101, guide post 2111, blank holder ring 2121, pin Ⅱ 2082, lower template 2131, punch 2141, screw 2151, nut 2161, push plate Ⅰ 2171, push plate Ⅱ 2172, rubber 2181, push rod 2191, screw Ⅲ 2023 ;

[0019] The mold handle 2041 is installed above the upper template 2011 through the screw II 2022. One end of the mold handle 2041 is provided with a cylindrical groove, and the other end is provided with a square groove. One end of the punch rod 2051 is embedded in the cylindrical groove. The other end protrudes from the opening of the cylindrical groove, and the protruding part is higher than the upper end surface of the mold handle 2041, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com