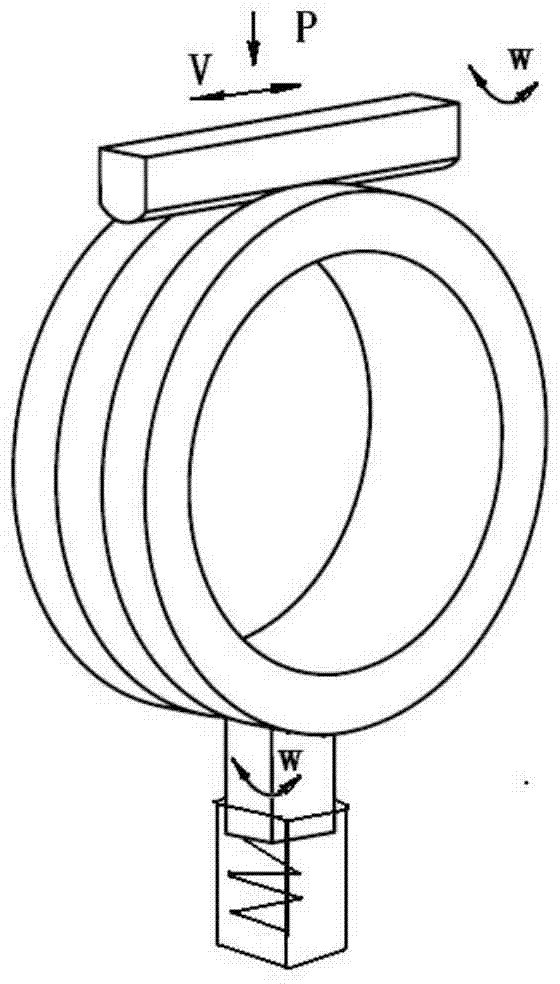

Device for spiral superfinishing of raceway of bearing inner race

A technology for processing device and bearing inner ring, which is applied in super-finishing machines, metal processing equipment, manufacturing tools, etc., can solve the problem of not being suitable for super-finishing of bearing inner ring raceway, and reduce waviness and improve roughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

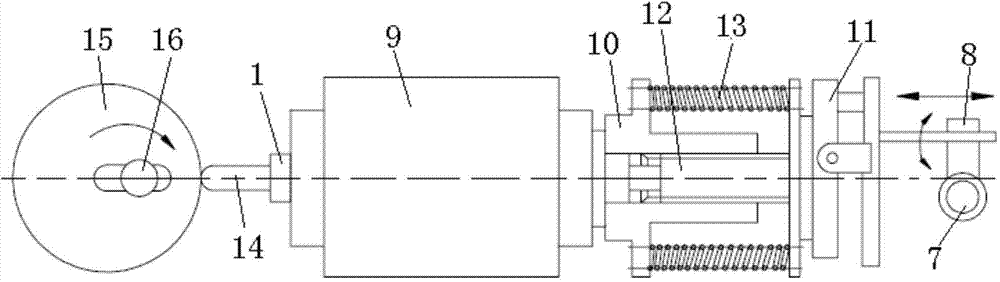

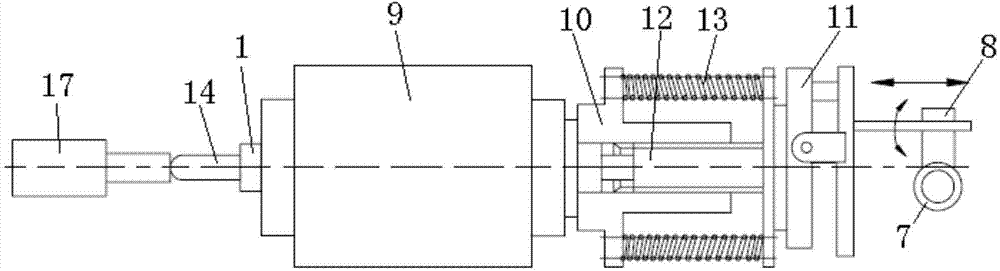

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] like figure 2 , shown in 3, the bearing inner ring raceway spiral superfinishing processing device of the present invention includes a space connecting rod oscillating oscillator 9, a spline sleeve 10, an oil stone swing head 11, a spline shaft 12, a tension spring 13, a push rod 14. Push device with adjustable stroke and speed.

[0017] The output end of the swing shaft 1 of the space connecting rod oscillating oscillator 9 is fixedly connected to the spline sleeve 10, the inside of the spline sleeve 10 is slidably connected to the spline shaft 12 matched with the spline sleeve 10, and the front end of the spline shaft 12 is fixedly connected to the oilstone swing head 11 , the oilstone swing head 11 and the spline sleeve 19 are connected by a tension spring 13, a push rod 14 is worn inside the swing shaft 1, and the front end of the push rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com