Preparation method of nano cellulose composite film capable of responding to humidity and obtained product

A technology of nano-cellulose and composite film, which is applied in the field of nano-cellulose composite film and its preparation, which can solve the problems of difficult processing and poor thermal stability of CNC film, and achieve good hygroscopic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

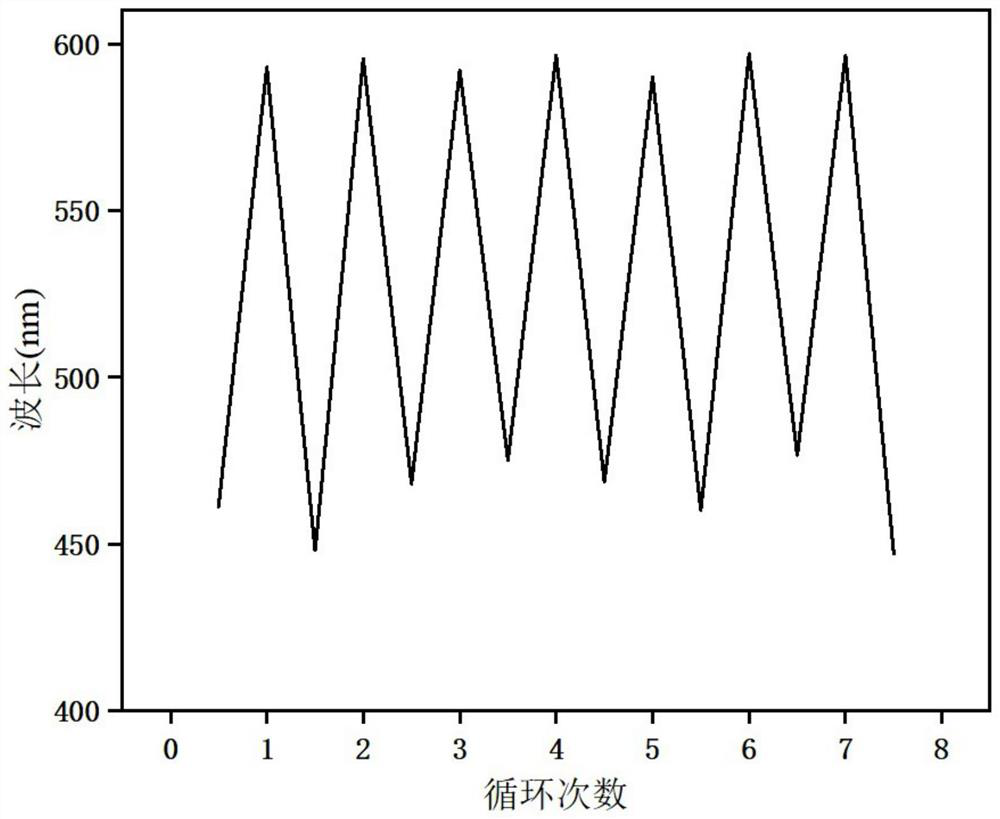

Image

Examples

Embodiment 1

[0031] (1) Configured as a CNC suspension with a concentration of 1.5wt%: add ultrapure water into the beaker, and turn on the magnetic stirrer, the stirring speed is 1000r / min; slowly add a certain mass of CNC powder in the vortex, mix for 1h, to ensure good dispersion.

[0032] Mixed with 1,3-butanediol BG in a mass ratio of 1:9 (BG: CNC suspension),

[0033] The mixed CNC suspension was treated with an ultrasonic cell disruptor in an ice-water bath, the probe was placed 1 cm below the liquid surface, the ultrasonic time was 2 s, the interval time was 2 s, and the total ultrasonic wave was 1 min. .

[0034] (2) The suspension treated in step (1) is placed in a polystyrene petri dish, and dried at 25° C. and 35% humidity. In this example, 3 mL of the suspension was placed in a polypropylene petri dish with a diameter of 35 mm, the liquid surface height was about 0.3 cm, and the thickness of the dried film was about 0.1-0.3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com