Wood pallet assembling and nailing device

A technology for binding equipment and wooden pallets, which is applied to wood processing appliances, staple U-shaped nail tools, nailing tools, etc., can solve the problems of reducing the binding efficiency of wooden pallets, unable to fix the positioning at the same time, etc., and achieve the effect of improving binding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

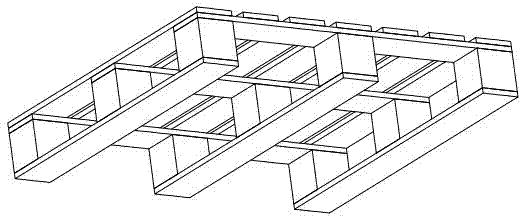

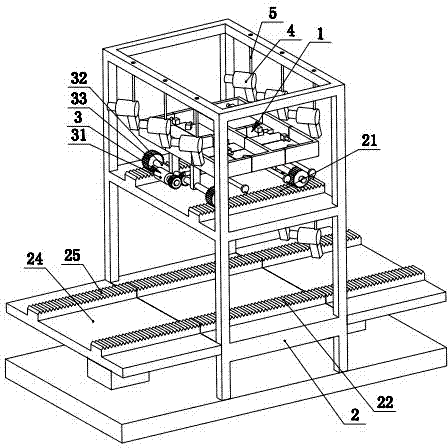

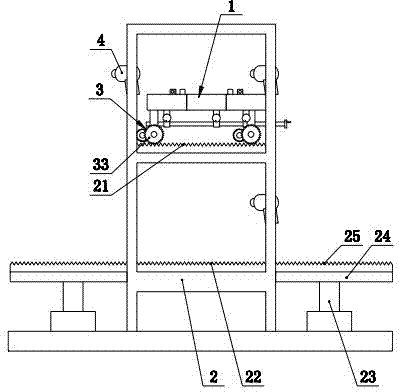

[0017] Such as figure 2 , 3 , 4, 5, and 6 show a kind of wooden pallet binding equipment, including a wooden pallet binding assembly line. The wooden pallet binding assembly line carries many pairs of wooden pallet stacking brackets 1. The assembly line includes a frame 2, and the frame 2 is provided with an upper row of racks 21 and a lower row of racks 22, and the upper row of racks 21 is parallel to the lower row of racks 22, and is located on the lower row of racks. 22, each wooden pallet stacking bracket 1 is connected with a drive device 3 that can drive it to move on the upper row of racks 21 or the lower row of racks 22, and the drive device 3 includes a motor 31 And the rotating shaft 32, the motor 31 and the rotating shaft 32 are all installed on the wooden pallet stacking bracket 1, the described rotating shaft 32 is linked with the output shaft of the motor 31, and the rotating shaft 32 is provided with a 21 or the rotating gear 33 that meshes and moves on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com