A full-load plant steam system for thermal power units

A technology for thermal power units and load plants, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as frequent load changes, large throttling losses, unfavorable operations, etc., achieve broad application prospects and improve thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

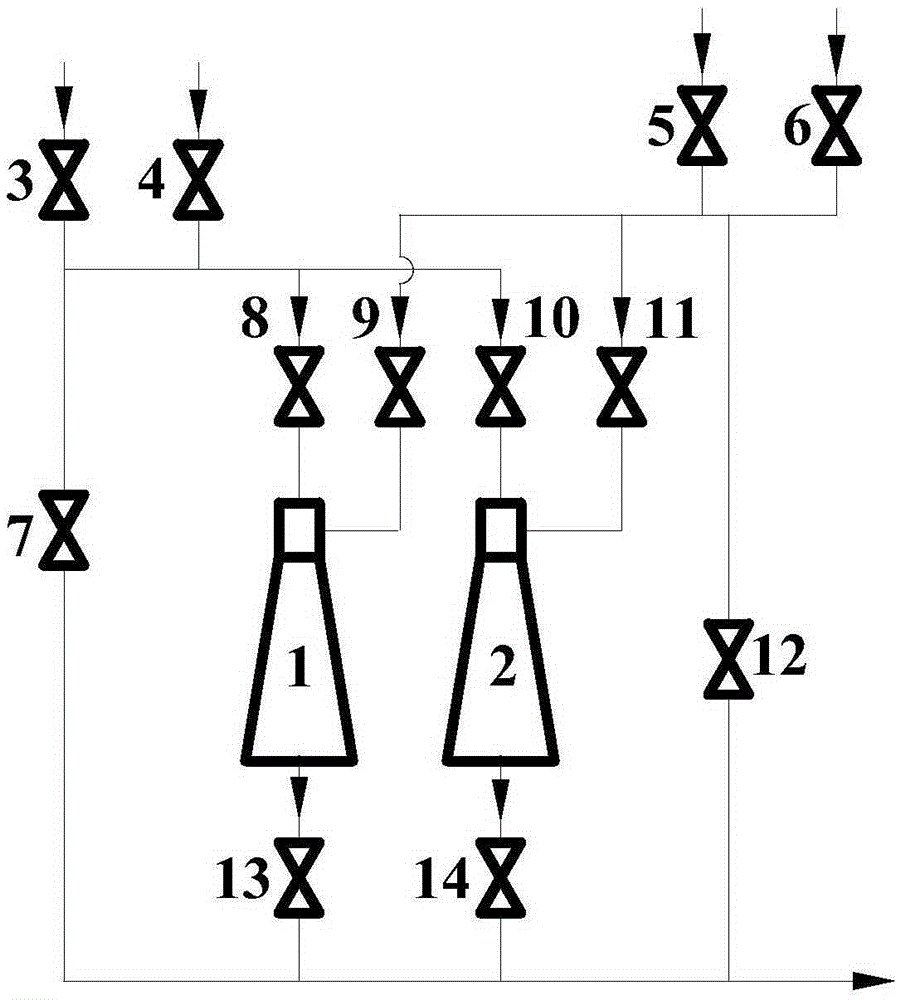

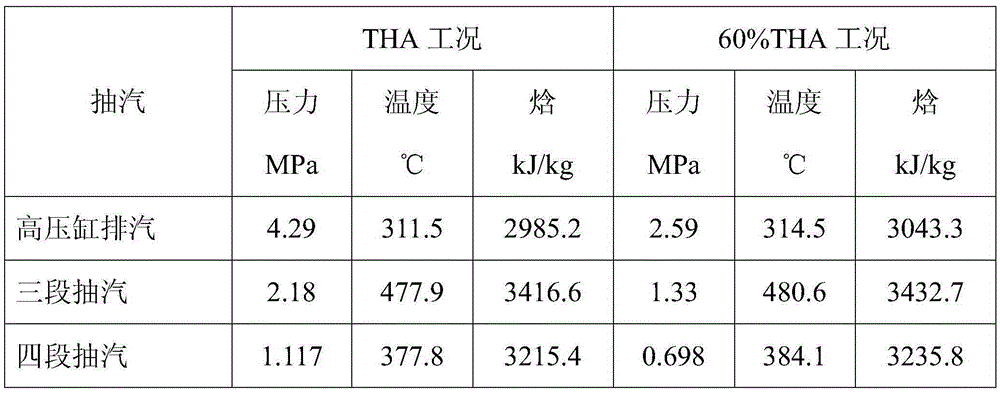

[0020] see figure 1 , the present invention comprises a high-pressure steam pipe and a low-pressure steam pipe; the entrance of the high-pressure steam pipe is provided with a high-pressure steam pipe inlet valve 3 or a four-stage extraction to control the high-pressure cylinder exhaust or four-stage steam extraction to enter the high-pressure steam pipe respectively. High-pressure steam pipe inlet valve 4; the entrance of low-pressure steam pipe is provided with four-stage steam extraction or five-stage steam extraction to enter low-pressure steam pipe respectively. Inlet valve 6;

[0021] The outlets of the high-pressure steam pipe and the low-pressure steam pipe are respectively connected to the high-pressure inlet and the low-pressure inlet of the small-flow ejector 1 and the large-flow ejector 2 with a parallel compression ratio of 1.2 to 1.8 and an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com