Refrigerator drawer sliding rail system

A slide rail and drawer technology, which is applied in the field of refrigerator drawer slide rail system, can solve the problems of unsmooth drawing, large space occupation, and high manufacturing cost of refrigerators, and achieve the effects of reducing production costs, improving installation efficiency, and saving installation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0038] This embodiment provides a refrigerator drawer slide rail system, which is suitable for the cooperation between the drawer and the slide rail, so that the installation structure between the two is simpler, the cost is low, and the drawer is pulled more smoothly and stably. Longer service life.

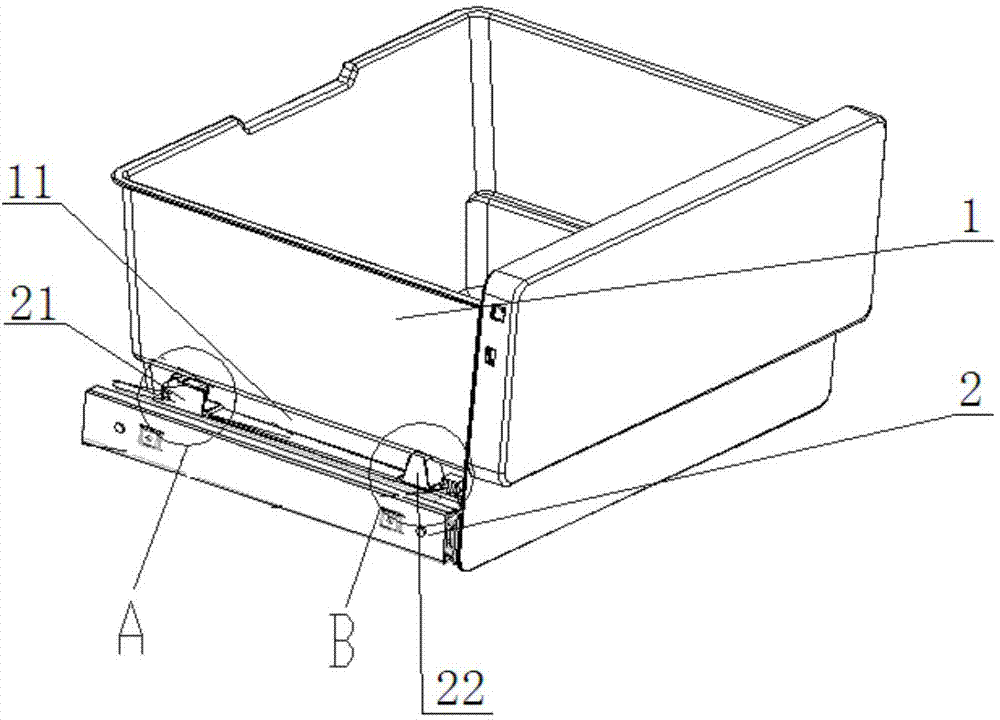

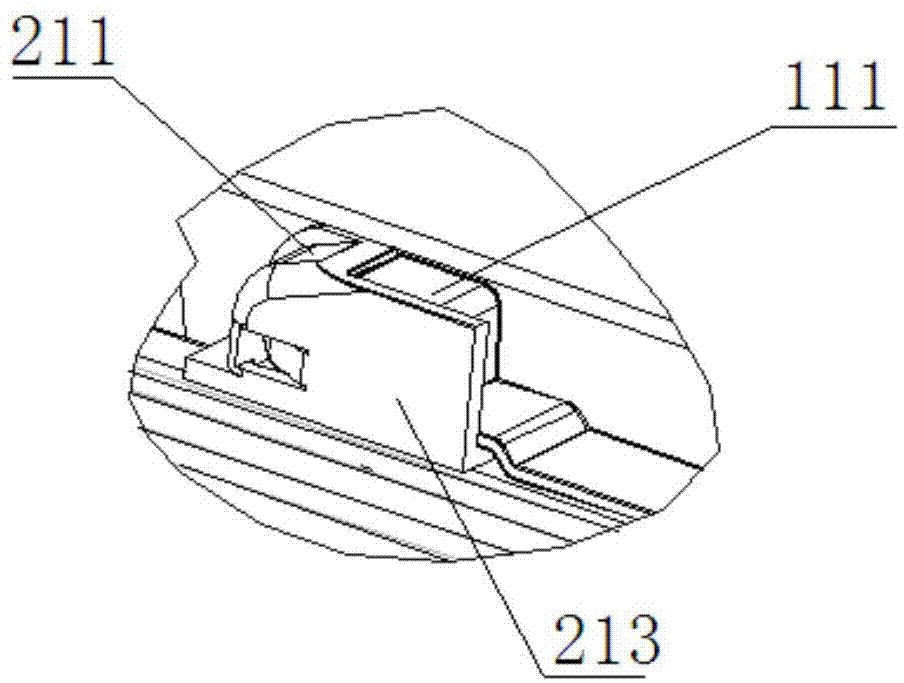

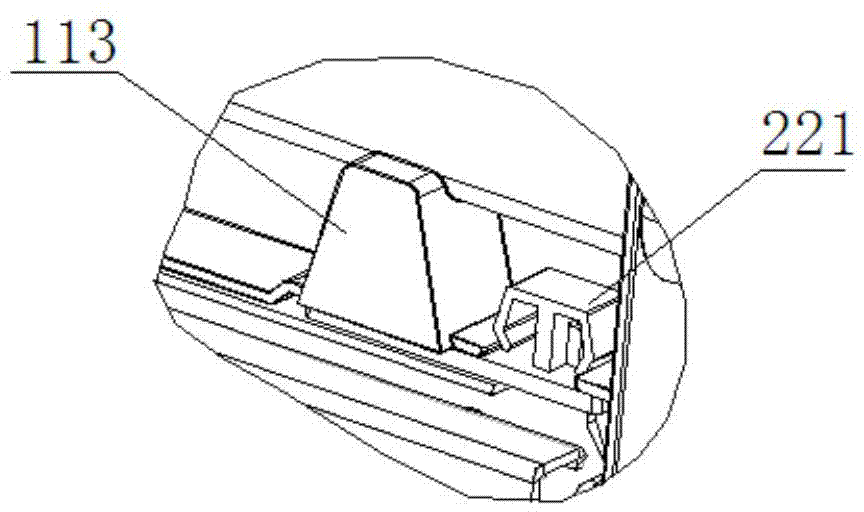

[0039] Specifically, the above-mentioned refrigerator drawer slide rail system includes a drawer 1 and a slide rail 2, wherein a positioning plate 11 is provided on both sides of the drawer, and a positioning boss 111 is provided at the front end of the positioning plate 11, and a positioning groove is provided at the rear end. 112; the front end of the moving slide rail of the slide rail 2 is provided with a front slide rail support block 21, and its rear end is provided with a rear slide rail suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com