Engine air distribution mechanism abrasion testing device

A gas distribution mechanism and wear test technology, applied in the direction of internal combustion engine testing, etc., can solve the problems of multi-material force, long test cycle of engine bench, long time, etc., and achieve the effect of less material force, short test cycle and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

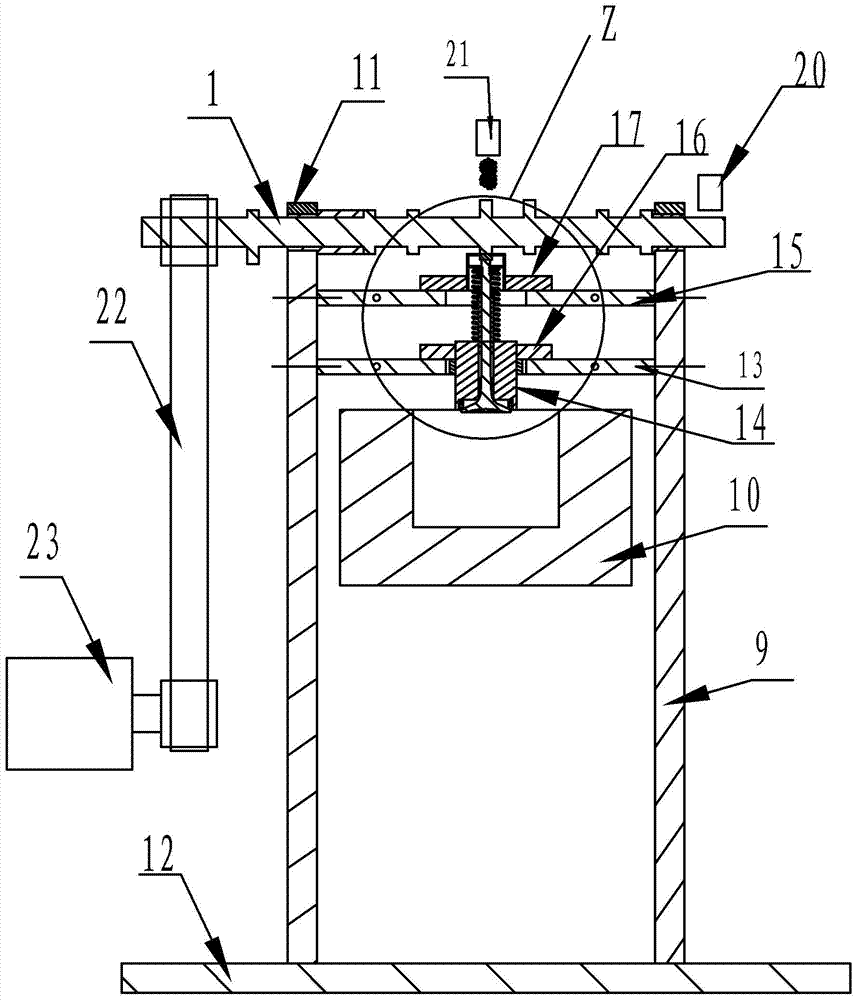

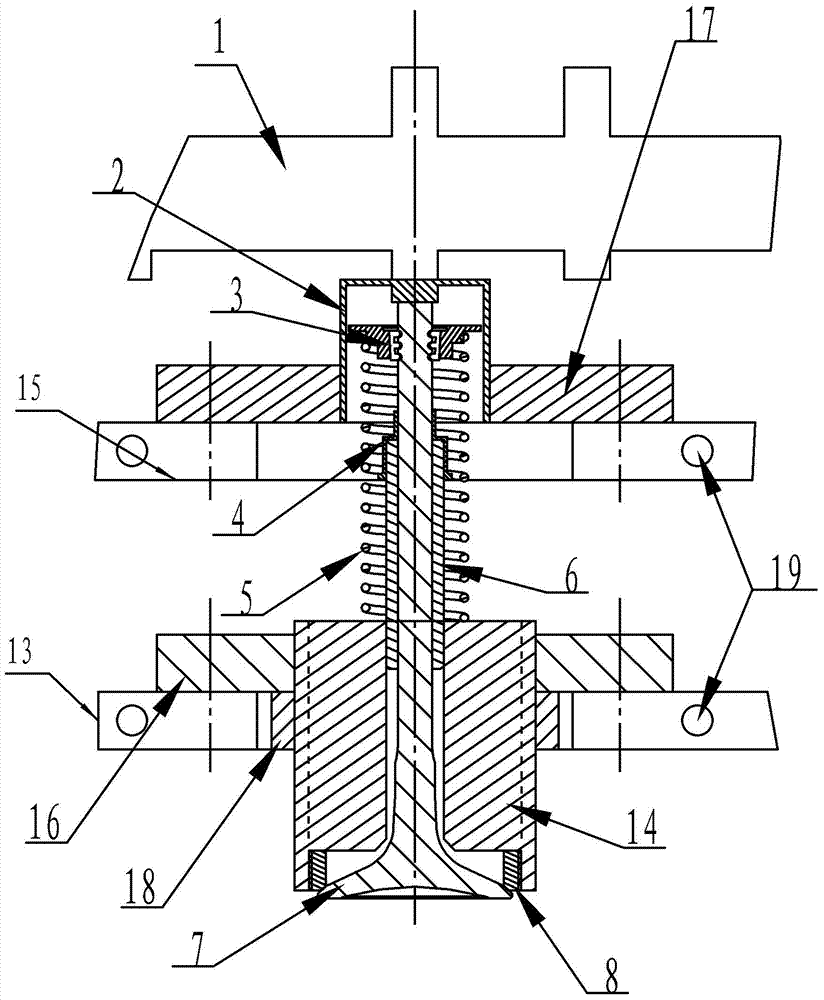

[0019] Embodiment 1, a kind of engine gas distribution mechanism wear test device is characterized in that: the horizontal base 12 is provided with two mutually parallel uprights 9, and the camshaft 1 with driving device is installed on the top of the uprights, between the two uprights An upper horizontal bracket 15 and a lower horizontal bracket 13 for fixing the valve train are installed,

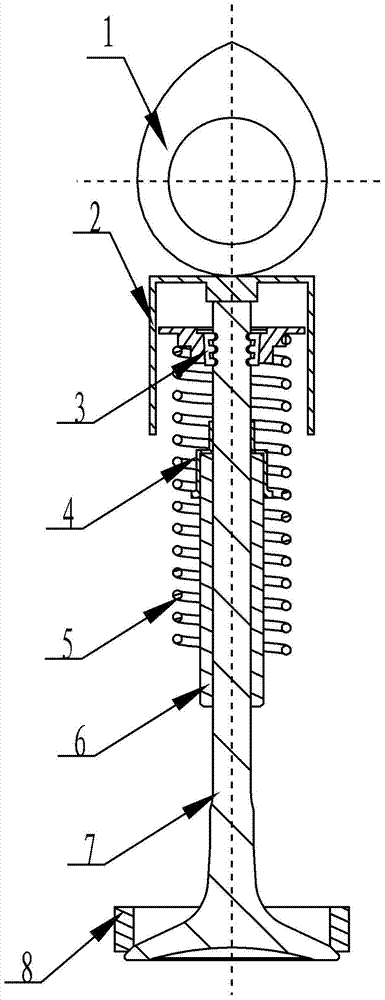

[0020] The valve lifter 2 is installed at the end of the vertically upward valve 7 of the valve distribution mechanism, the valve guide 6 is installed in the inner hole of the seat ring seat 14, and the valve spring 4 is set on the valve lock clip 3 together with the spring seat. The valve seat ring 8 is installed in the seat ring seat 14,

[0021] The upper horizontal bracket is equipped with a guide plate 17, the lower horizontal bracket is equipped with a positioning plate 16, the seat ring seat 14 passes through the center hole of the positioning plate, and is fixed on the lower side ...

Embodiment 2

[0022] Embodiment 2, a kind of engine gas distribution mechanism wear test device is characterized in that: two mutually parallel uprights 9 are arranged on the horizontal base 12, the camshaft 1 with driving device is installed on the top of the uprights, between the two uprights An upper horizontal bracket 15 and a lower horizontal bracket 13 for fixing the valve train are installed,

[0023] The valve lifter 2 is installed at the end of the vertically upward valve 7 of the valve distribution mechanism, the valve guide 6 is installed in the inner hole of the seat ring seat 14, and the valve spring 4 is set on the valve lock clip 3 together with the spring seat. The valve seat ring 8 is installed in the seat ring seat 14,

[0024] The upper horizontal bracket is equipped with a guide plate 17, and the lower horizontal bracket is equipped with a positioning plate 16. The seat ring seat 14 passes through the center hole of the positioning plate, and is fixed on the lower side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com