Pressure test sealing tool for lng gas cylinders for vehicles

A pressure test and gas cylinder technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of easy aging of rubber pads, poor sealing performance, and potential safety hazards, and achieve tooling The effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

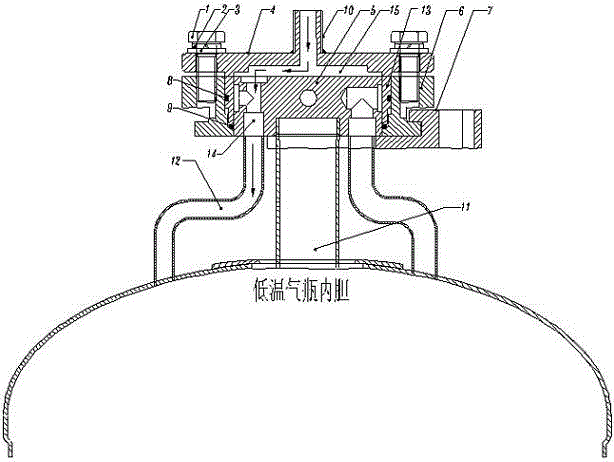

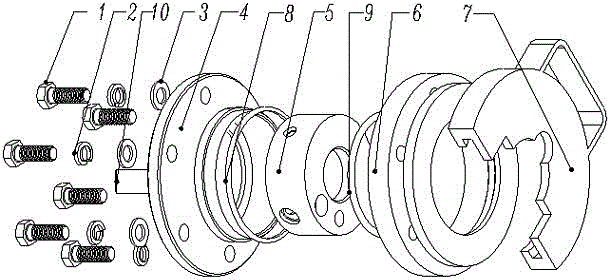

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 with figure 2 A pressure test sealing tool for LNG gas cylinders for vehicles is shown, which includes a support tube 11 arranged at the end of the LNG gas cylinder, and a gas cylinder dispensing head 5 installed at the head of the support tube 11 . The gas cylinder distribution head 5 is provided with an upper sealing cover 4, the bottom surface of the upper sealing cover 4 extends downwards to form an annular baffle 13, the inner wall of the annular baffle 13 is close to the gas cylinder distribution head 5 and Its end is no more than the bottom surface of gas cylinder distribution head 5. The outer side of the annular baffle 13 and the gas cylinder distribution head 5 is provided with a lower sealing cover 6 , and the bottom of the lower sealing cover 6 is provided with a connecting plate 7 for clipping the lower sealing cover 6 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com