Lithium-ion battery, multi-element positive electrode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of multi-element lithium-ion battery positive electrode materials and its preparation, can solve the problem of insufficient bonding of coating elements and material surfaces, affecting high-voltage and high-temperature performance of materials, and crystallization damage on the surface of ternary materials and other problems, to achieve the effects of reducing Li/Ni mixing, improving electrical conductivity, and superior high-voltage and high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

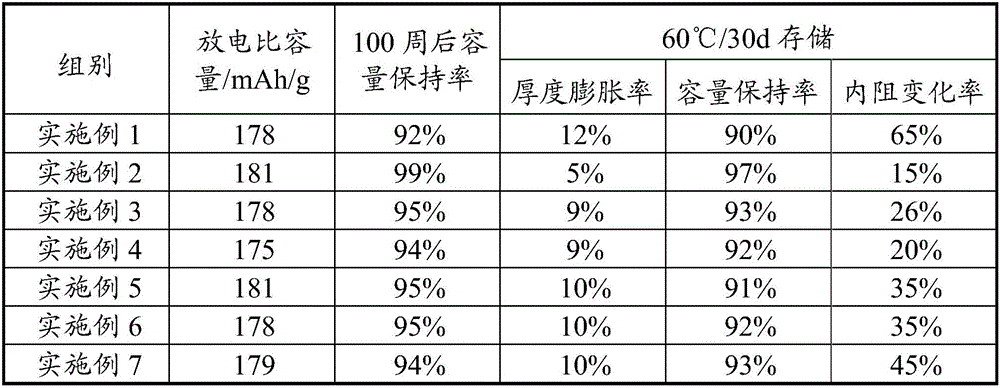

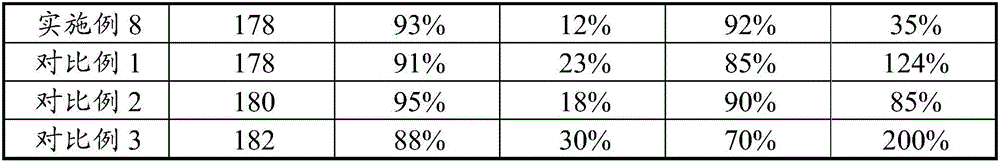

Examples

Embodiment 1

[0033] (1) Preparation of nickel-cobalt-manganese hydroxide precursor: use pure water as the bottom liquid, raise the temperature to 60°C-75°C, control the stirring speed at 160r / min-180r / min, add ammonia water to adjust the pH value of the bottom liquid to 10.3 About; the nickel-cobalt-manganese mixed salt solution with a total ion concentration of 60g / L, the sodium hydroxide solution with a concentration of 30wt.%, and the ammonia water with a concentration of 18vol.% are continuously pumped into the bottom liquid in parallel, and the nickel salt is nickel sulfate , the cobalt salt is cobalt sulfate, the manganese salt is manganese sulfate, and the obtained reaction solution is configured; precipitation reaction occurs at 60°C to 75°C, and the solid content of the slurry in the reaction system is controlled to be 260g / L to 300g / L, and kept The above alkalinity and pH value, the reaction feed liquid continuously flows out from the upper overflow port of the reaction kettle and...

Embodiment 2

[0039] Different from Example 1, in step (2) nickel-cobalt-manganese hydroxide is carried out Ti surface doping treatment, Ti surface doping amount is 0.5mol%, modification temperature / time is 500 DEG C / 5h, step (4 ) The treatment temperature / time in the surface Mg treatment of nickel-cobalt-manganese ternary material B is 850°C / 5h, step (5) nickel-cobalt-manganese ternary material Al 2 o 3 The treatment temperature / time in the coating treatment is 500°C / 5h; other raw materials, steps and parameters are the same as in Example 1. The molecular formula of the modified ternary material D is Li 1.05 Ni 0.495 co 0.195 mn 0.295 Ti 0.005 Mg 0.005 al 0.005 o 2 (I CP measurement), the thickness of the magnesium-containing transition layer is 0.8-1.5 μm.

Embodiment 3

[0041] The difference from Example 1 is that in step (2) nickel-cobalt-manganese hydroxide is subjected to Ti surface doping treatment, the Ti surface doping amount is 2mol%, the modification temperature / time is 500°C / 5h, step (4) In the surface Mg treatment of nickel-cobalt-manganese ternary material B, the Mg modification treatment temperature / time is 800°C / 5h, step (5) nickel-cobalt-manganese ternary material Al 2 o 3 The treatment temperature / time in the coating treatment is 500°C / 5h; other raw materials, steps and parameters are the same as in Example 1. The theoretical chemical formula of material D is Li 1.05 Ni 0.485 co 0.19 mn 0.295 Ti 0.02 Mg 0.005 al 0.005 o 2 (ICP test analysis), the thickness of the magnesium-containing transition layer is 0.6-1.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com