Fire alarm and fire extinguishing system for oil tank

A fire alarm and fire extinguishing system technology, which is applied in fire rescue and other directions, can solve the problems of unsatisfactory flow and pressure, high technical implementation cost, etc., and achieve the effects of high alarm position accuracy, low technical implementation cost, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

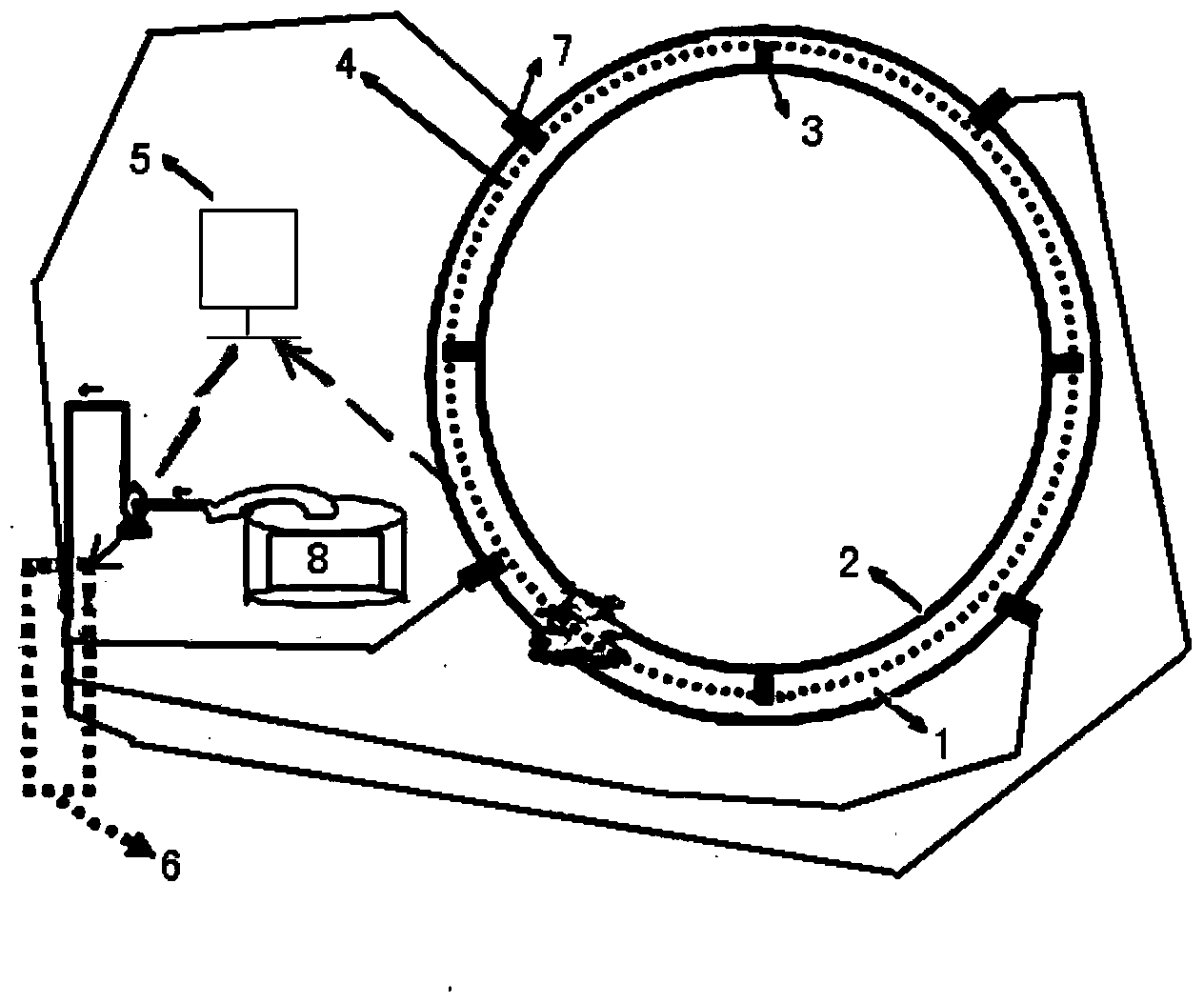

[0019] Such as figure 1 As shown, there is a foam baffle in the annular space between the foam weir plate and the tank wall of the oil tank. The foam baffle extends below the oil surface in the oil tank and leaves a gap with the tank wall. The foam baffle separates the foam weir The annular space between the plate and the tank wall is divided into several areas. The fiber grating alarm system alarms independently in each area, and transmits the alarm signal to the linkage console. The linkage console transmits the alarm signal to the solenoid valve in the corresponding area, and the solenoid valve controls The signal indicates that the foam injection device in the corresponding area is automatically activated, and the foam fire extinguishing agent is sprayed at fixed points to extinguish the fire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com