mechanical energy engine

An engine and mechanical energy technology, applied in the direction of machine/engine, variable displacement engine, reciprocating piston engine, etc., can solve the problem of engine energy consumption and workmanship, and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

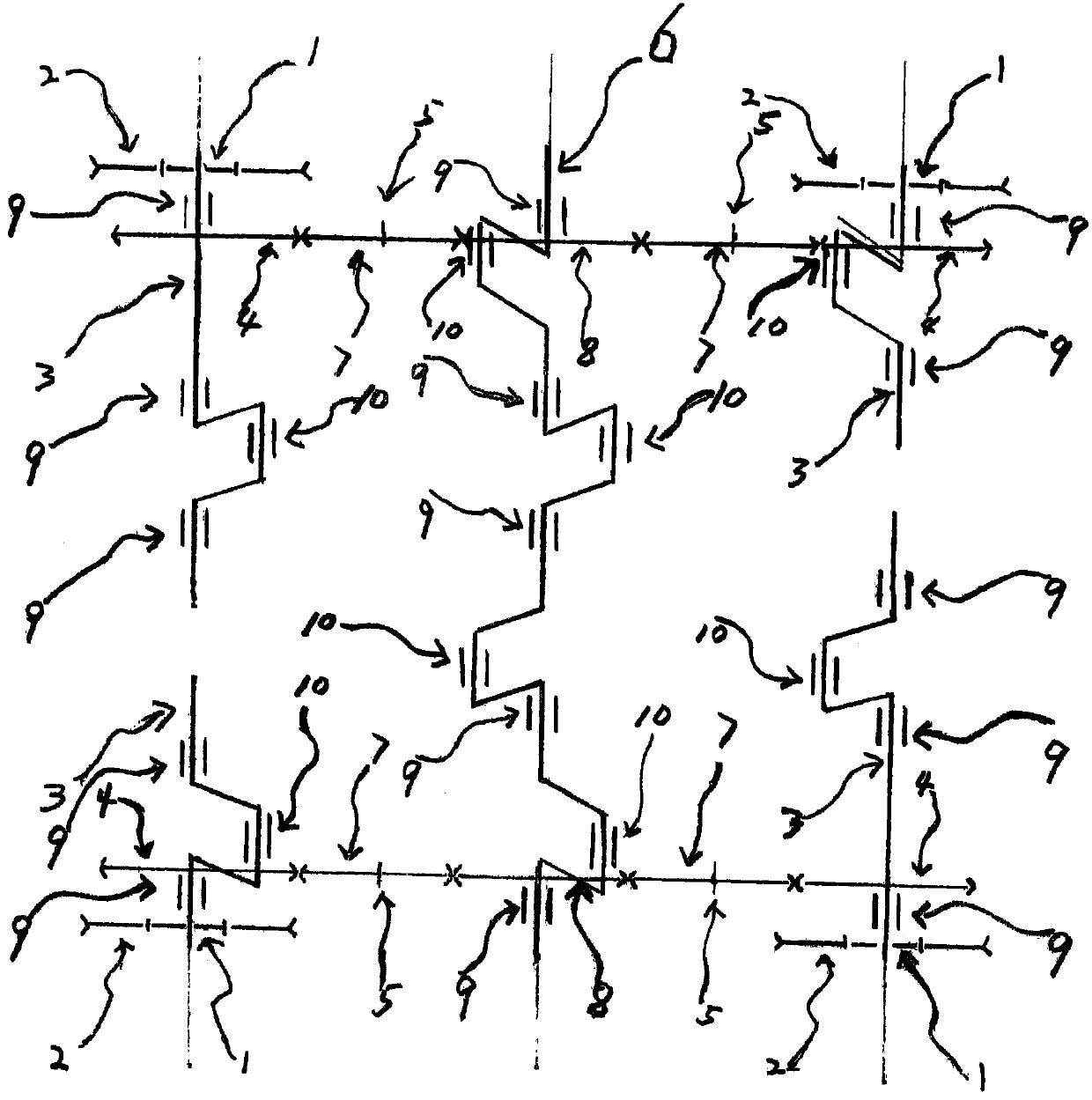

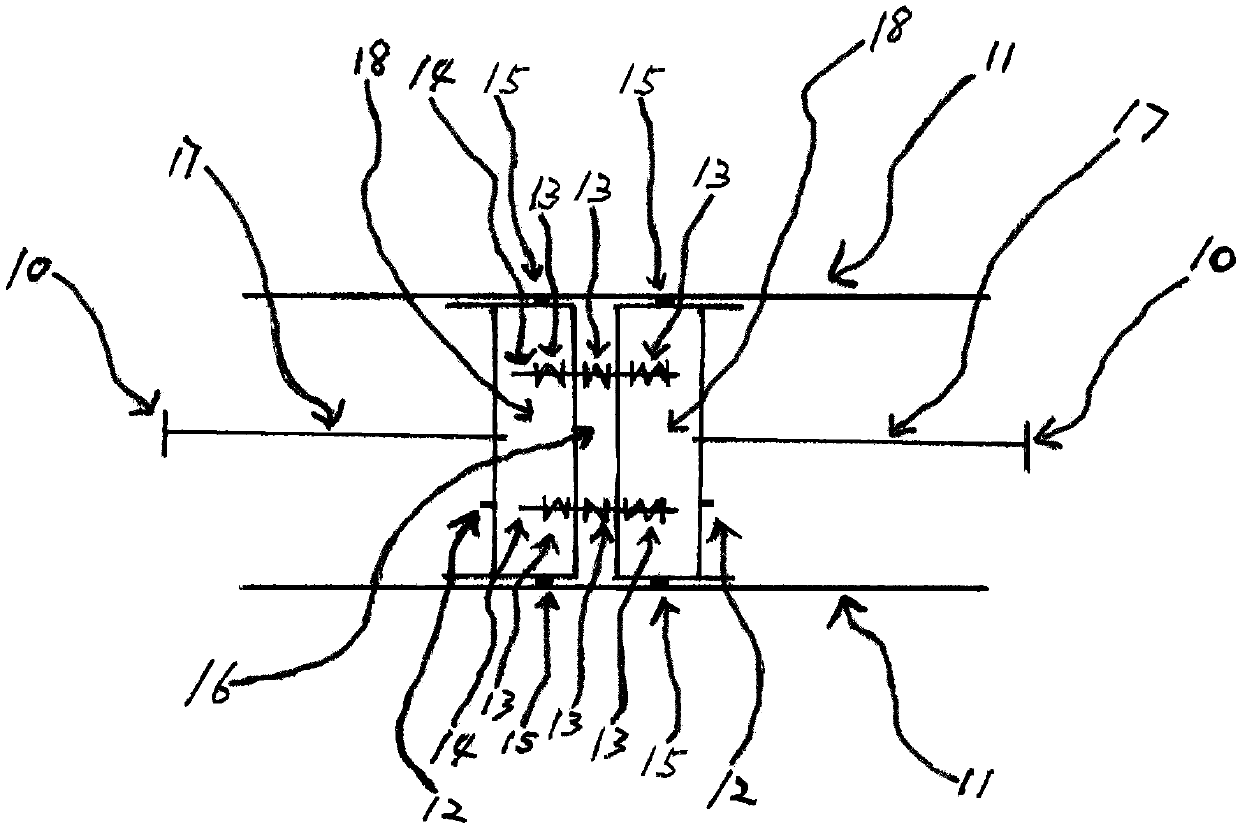

[0009] A mechanical energy engine such as figure 1 As shown, it includes oval cylinder 11, piston 18, piston shaft 12 and piston slip ring 15; also includes flywheel 1, pulley 2, journal seat 9, four secondary crankshafts 3, first synchronous gear 4, gear shaft 5 , second synchronous gear 8, main crankshaft 6, third synchronous gear 7, spring 13, connecting rod 14 and transmission rod 17; each auxiliary crankshaft 3 has a connecting pin 10, and four auxiliary crankshafts 3 are arranged in two matrixes row and two rows, the four auxiliary crankshafts 3 and the main crankshaft 6 are respectively limited by the fixed journal seats 9 and the respective main journals of the four auxiliary crankshafts 3 and the main crankshaft 6 are respectively connected to the corresponding journals in a manner of autorotation. The seats 9 are in motion fit, and the flywheel 1, the pulley 2 and the first synchronous gear 4 are fixed on the respective main journals of the four auxiliary crankshaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com