Packaging structure for high-efficiency and energy-saving reflective focused type solar power generation device

A power generation device, high-efficiency and energy-saving technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of reducing the use of monocrystalline silicon, small energy distribution density, and occupying a huge area, so as to achieve low power generation costs and long service life , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

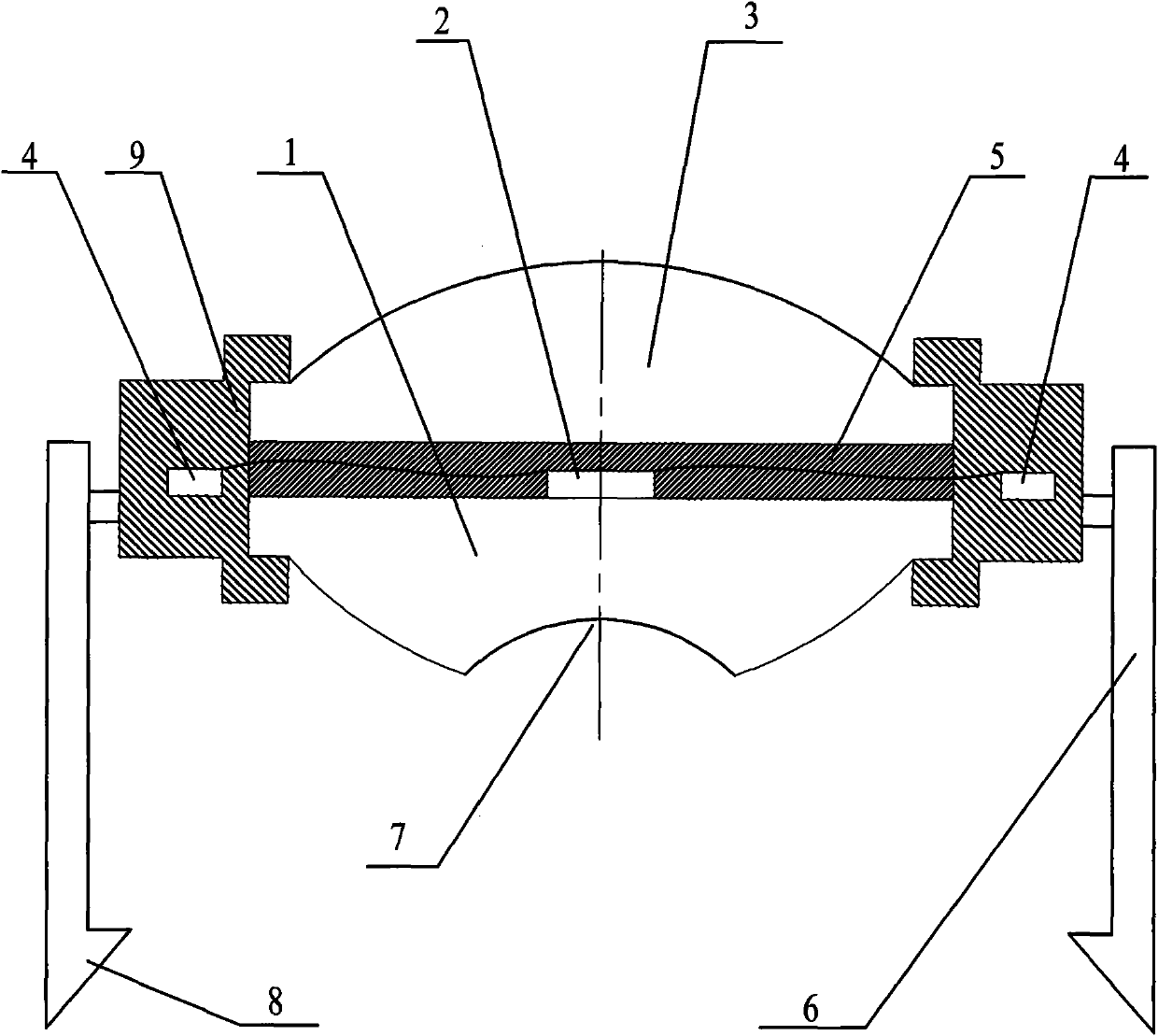

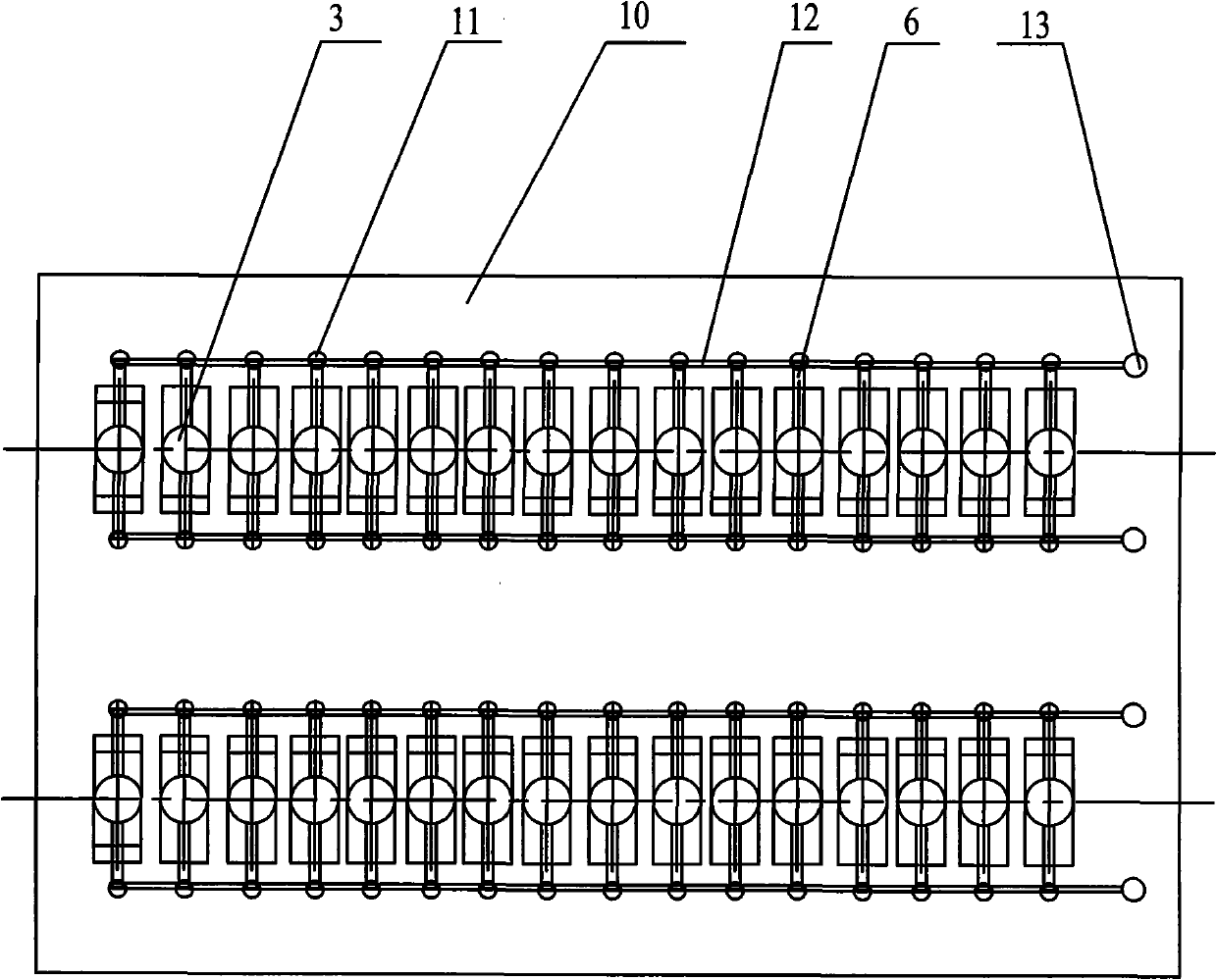

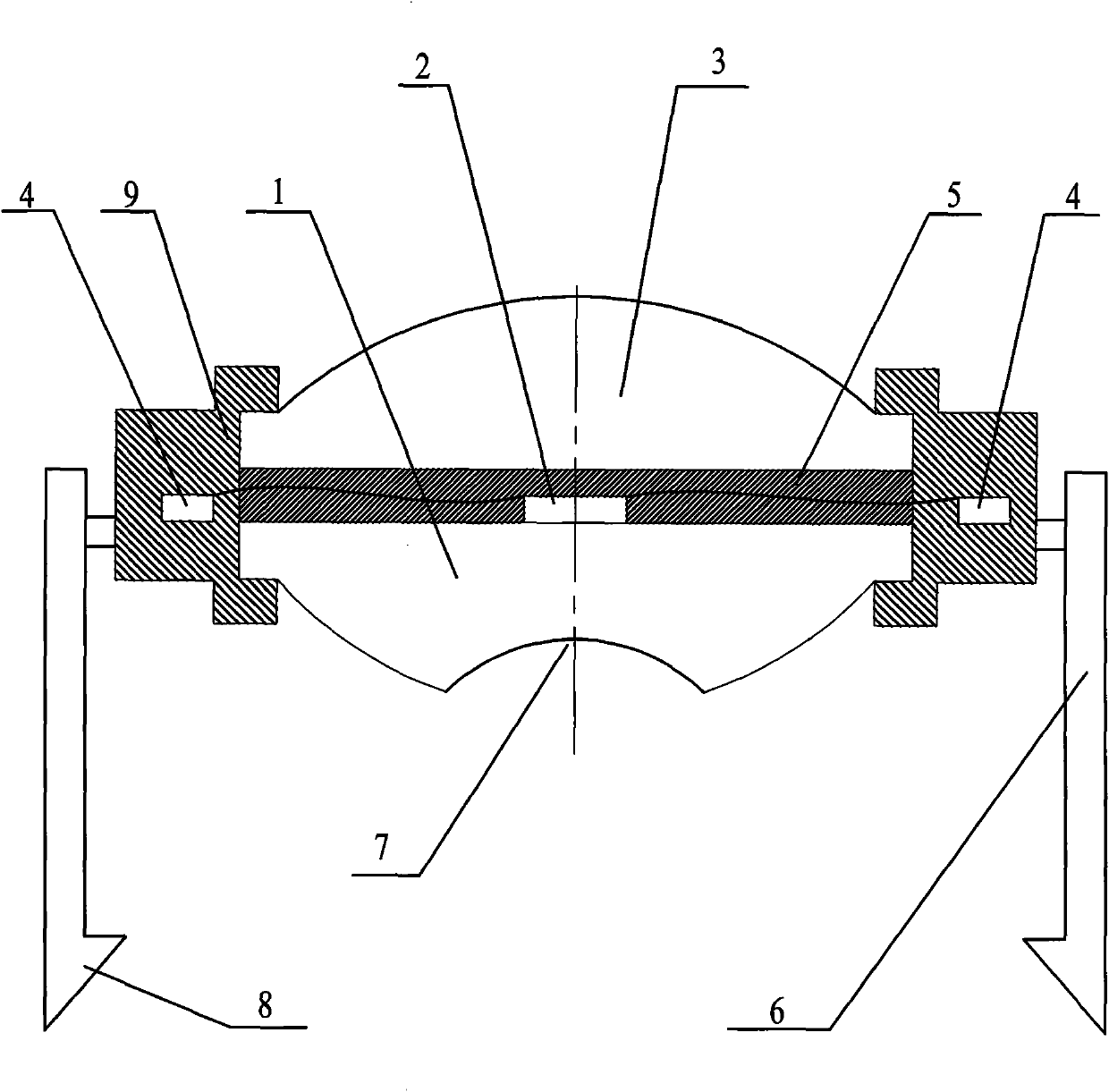

[0037] The focusing lens 3 is a single-convex solid lens with an outer diameter of 12 mm. The height of the focusing lens 3 body is 6 mm. The focusing lens 3 is made of highly transparent glass material.

[0038] The body of the reflective substrate 1 is made of crystal. There is an inner groove 7 in the direction where the body of the reflective substrate 1 connects with the bottom plate 10. The inner groove 7 and the side wall of the hemispherical reflective substrate 1 form a total reflection surface.

[0039] The conductive electrode 4 is fixed in the fixed bracket 9, the fixed bracket 9 is provided with a conductive pin 6, the conductive electrode 4, the fixed bracket 9, the conductive pin 6 and the lower hook body 8 positioned at the lower end of the conductive pin 6 can be integrally formed .

[0040] In the packaging process, the power generation chip 2 is electrically connected to the conductive electrode 4 through a conductive wire, and then the main body of the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com