Method for testing liquid absorption rate of battery diaphragm

A test method and battery diaphragm technology, applied in the direction of using material absorption and weighing, etc., can solve the problems of poor reproducibility and accuracy of test results, large diaphragm quality errors, and large impact on test results. The process is easy to standardize and quantify, Precise measurement, testing equipment and conditions require less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

[0027] A method for testing the liquid absorption rate of a battery diaphragm, comprising the following steps:

[0028] (1) Cut a rectangular sample at a place where the battery separator to be tested is flat and uniform;

[0029] (2) The thickness of the sample is measured by the thickness gauge, and the calculated volume is V 1 ; The thickness of the intercepted diaphragm sample should be uniform, the surface should be flat, and the area should be 1-100cm 2 ;

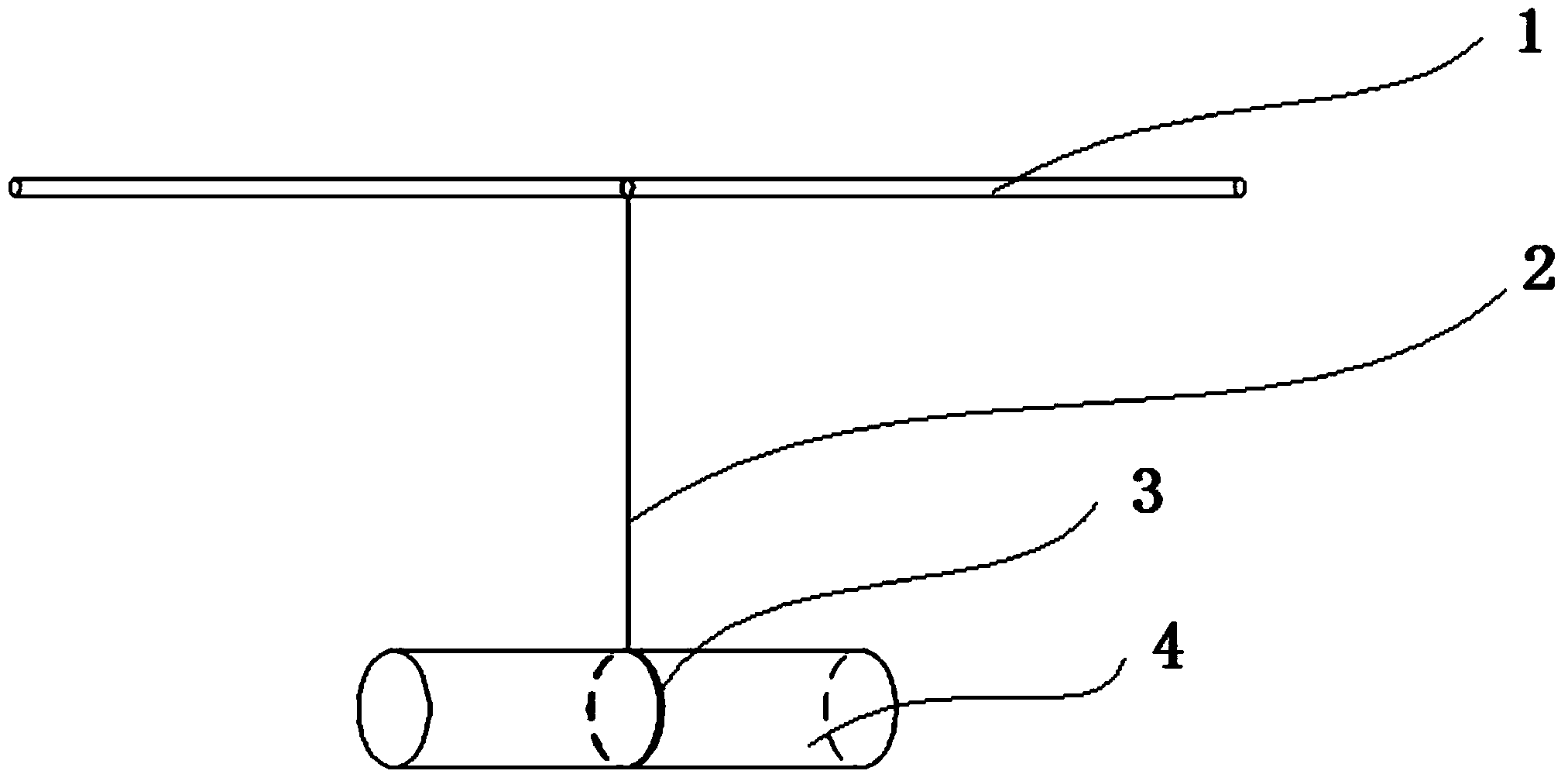

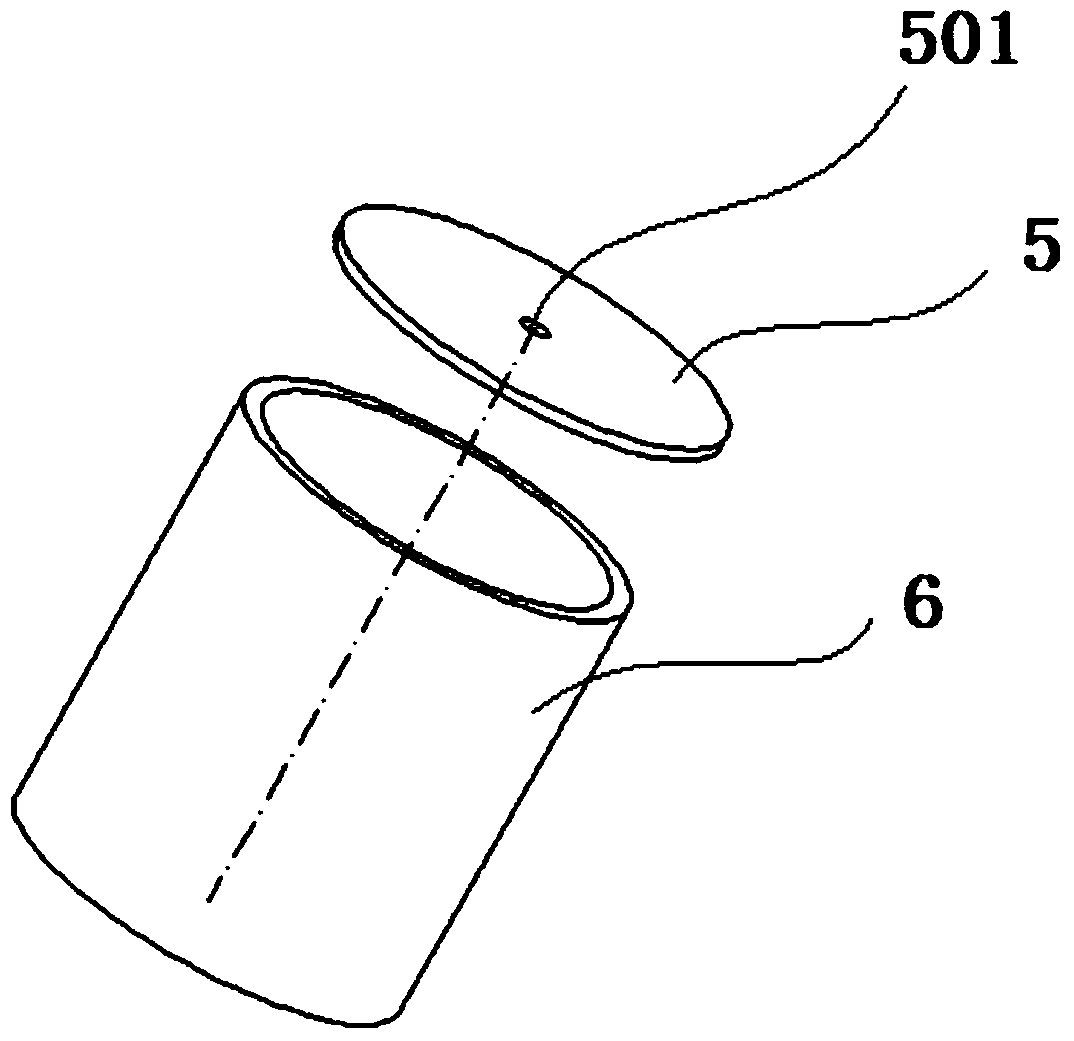

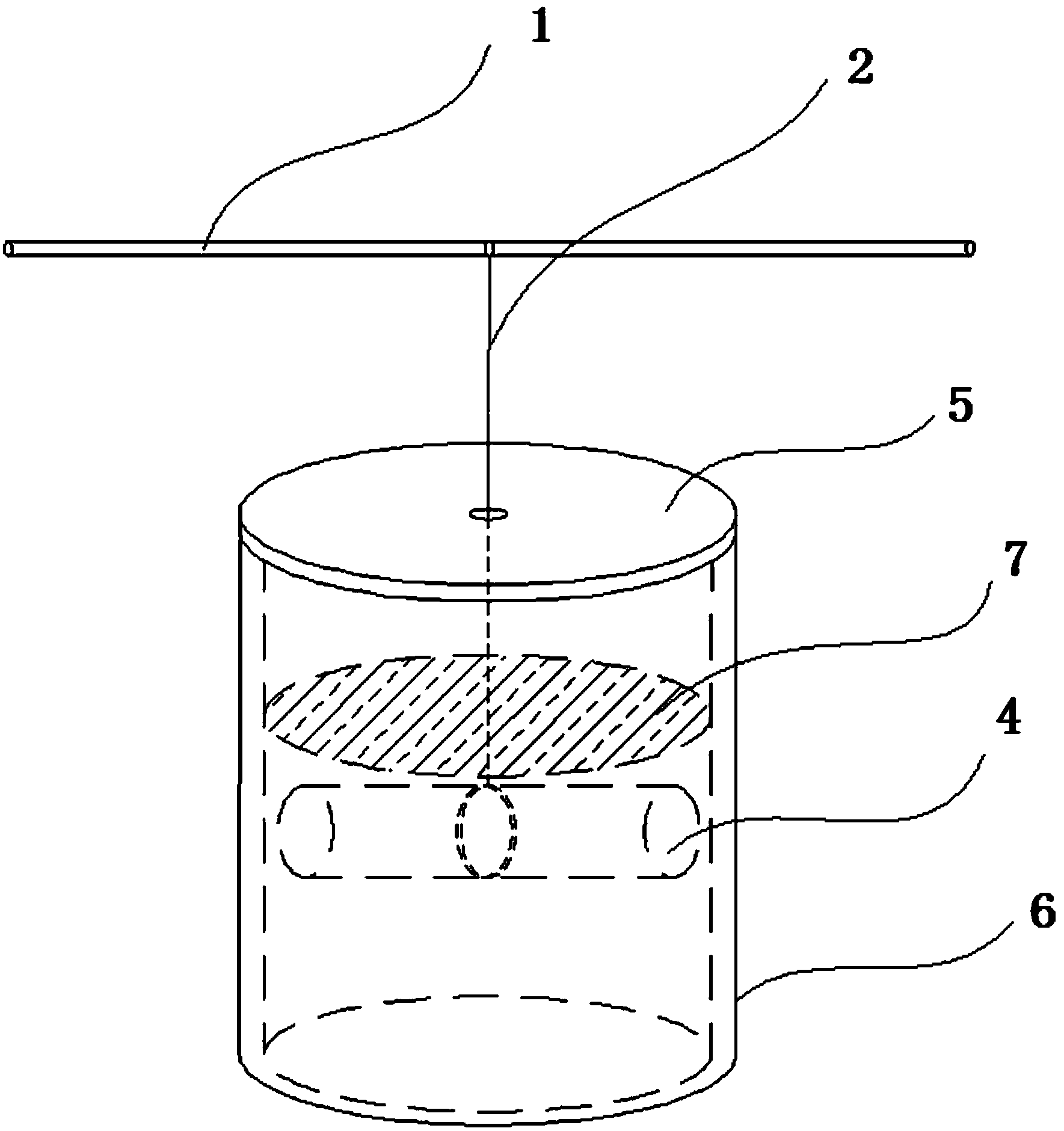

[0030] (3), Put the glass container 6 and the cover 5 containing the electrolyte solution inside (refer to figure 1 , figure 2 with image 3 ) on an electronic balance with an accuracy of 0.0001g. After the value is stable, the reading is cleared; the thin plastic wire 2 passes through the small hole 501 of the glass cover 5, one end is tied to the glass rod 1, and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com