Contiguous printed circuit board and its cutting and transplanting process

A technology for printed circuit boards and process methods, applied in the field of electronics, can solve the problems of low connection accuracy and large connection gap, and achieve the effects of ensuring the connection accuracy, reducing the connection gap, and ensuring the splicing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

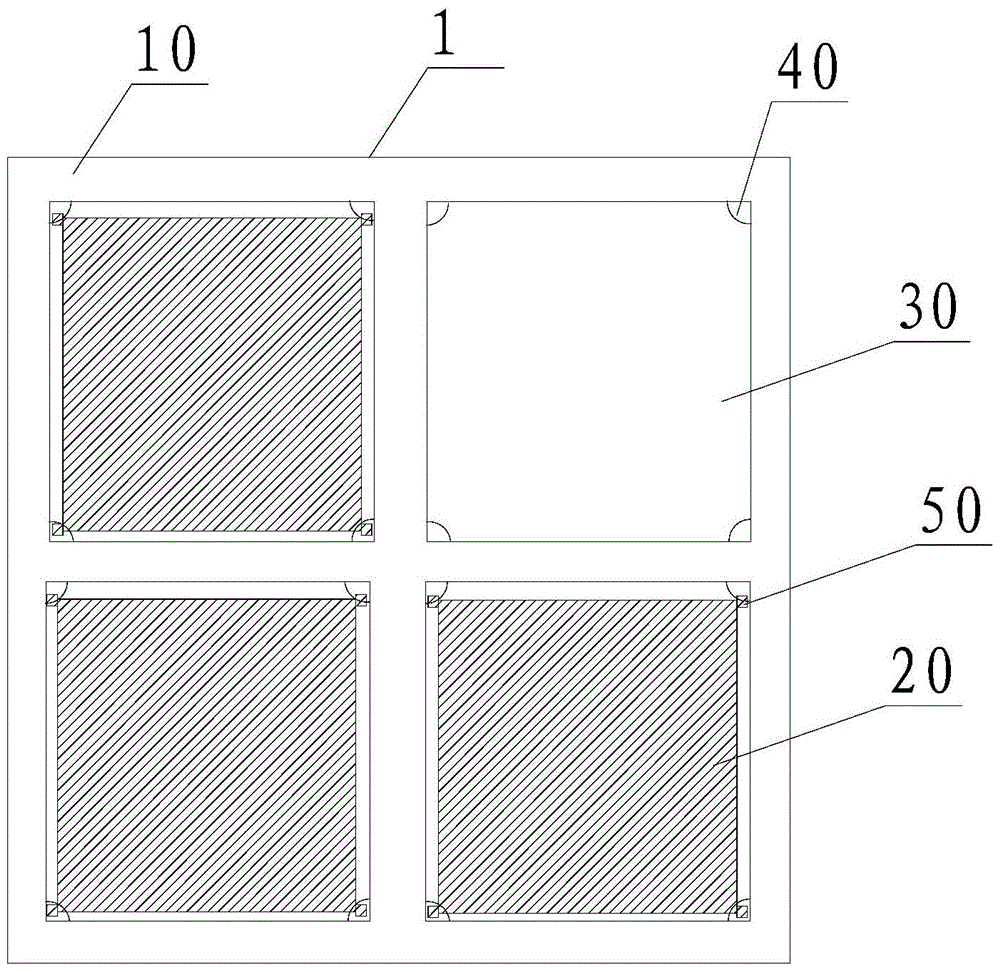

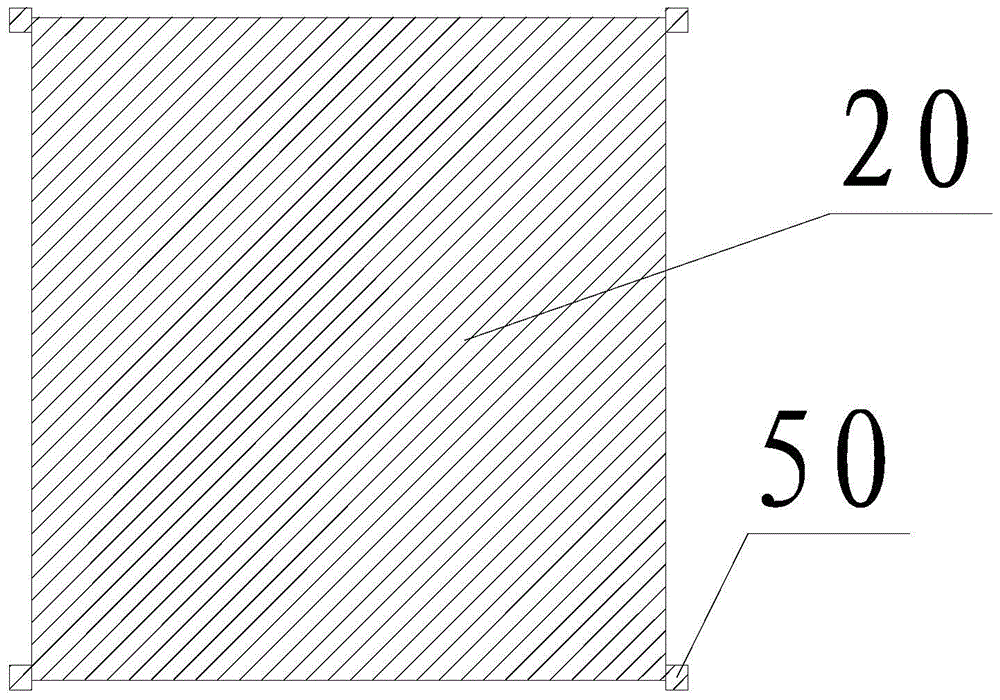

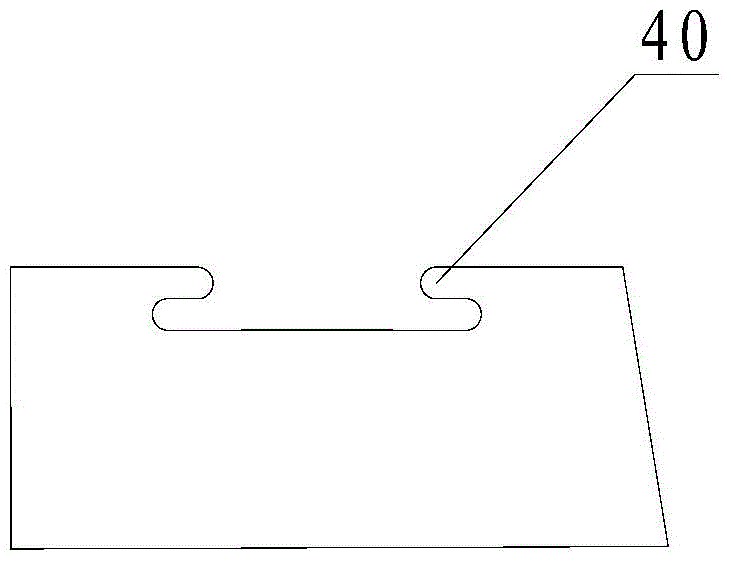

[0024] Such as figure 1 and figure 2 As shown, a contiguous printed circuit board 1 provided in Embodiment 1 of the present invention includes a substrate 10 and at least one single-piece board 20, and the substrate 10 is also provided with a mounting hole 30, and the mounting hole 30 is connected to the The shape of the single-piece plate 20 matches, and the edge of the installation hole 30 is uniformly provided with a plurality of outward flanged limiting parts 40;

[0025] The edge of the monolithic plate 20 is evenly provided with the same number of protruding parts 50 as the limit part, and the limit part 40 is matched with the protruding part 50; the limit part 40 on the substrate 10 is used for The protruding portion 50 on the single board 20 is buckled. The above-mentioned limiting parts with flanging are correspondingly distributed on both sides of the substrate. After being stuck, the protruding part can just be stuck in the cavity formed by the limiting parts on ...

Embodiment 2

[0042] Based on the same inventive concept, Embodiment 2 of the present invention also provides a cutting and transplanting process method for a contiguous printed circuit board. Since the problem-solving principle of this method is based on the structural principle of the aforementioned contiguous printed circuit board, repeated The place will not be repeated.

[0043] Such as Figure 5 As shown, Embodiment 2 of the present invention also provides a cutting and transplanting process for continuous printed circuit boards, including the following steps:

[0044] Step S100, using the second-dimensional optical measurement equipment to determine the offset direction of the optical points of a continuous printed circuit board;

[0045] Step S200, determine the position of the cutting positioning hole of another piece of continuous printed circuit board, perform the cutting operation, separate the cut substrate from the single board, and determine the deviation of the optical poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com