Flexible printed circuit board reinforcement steel piece pasting method

A technology of reinforcing steel sheets and flexible printing, which is applied in the fields of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of workload efficiency, cracking of solder feet of components, etc., and achieve the goal of improving production efficiency and reducing workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

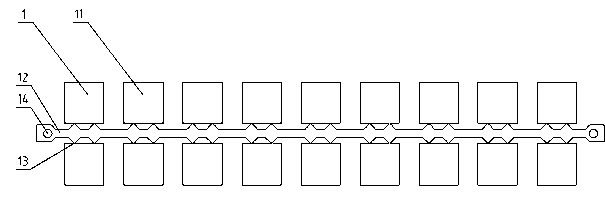

[0022] Such as figure 1 As shown, the reinforcing steel sheet 1 includes a reinforcing steel sheet unit 11 and a connecting strip 12, and the reinforcing steel sheet unit 11 and the connecting strip 12 are connected by two peak angles 13, and the sharp angle of the peak angle 13 is in line with the complementary The strong steel sheet unit 11 is connected on one side, and the two ends of the connecting bar 12 are respectively provided with steel sheet positioning holes 14 .

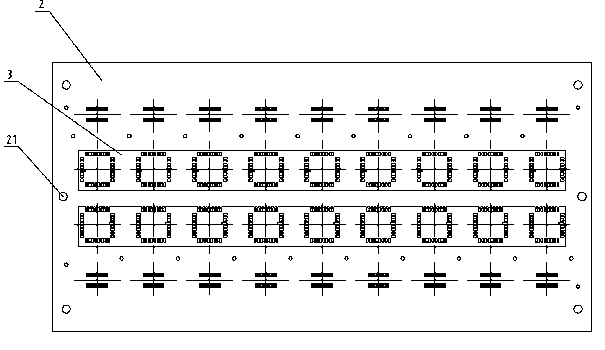

[0023] Such as figure 2 As shown, two ends of the circuit board substrate 2 are respectively provided with substrate positioning holes 21 . On the circuit board substrate 2 where the reinforcing steel sheet 1 needs to be pasted, paste a whole strip of pure rubber 3 with a width greater than the width of the reinforcing steel sheet 1 of 0.5mm

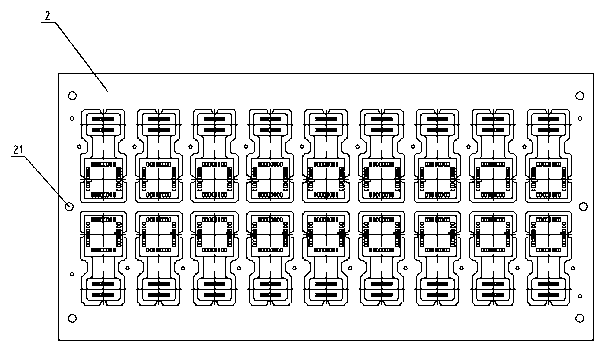

[0024] Such as image 3 As shown, the circuit board su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com