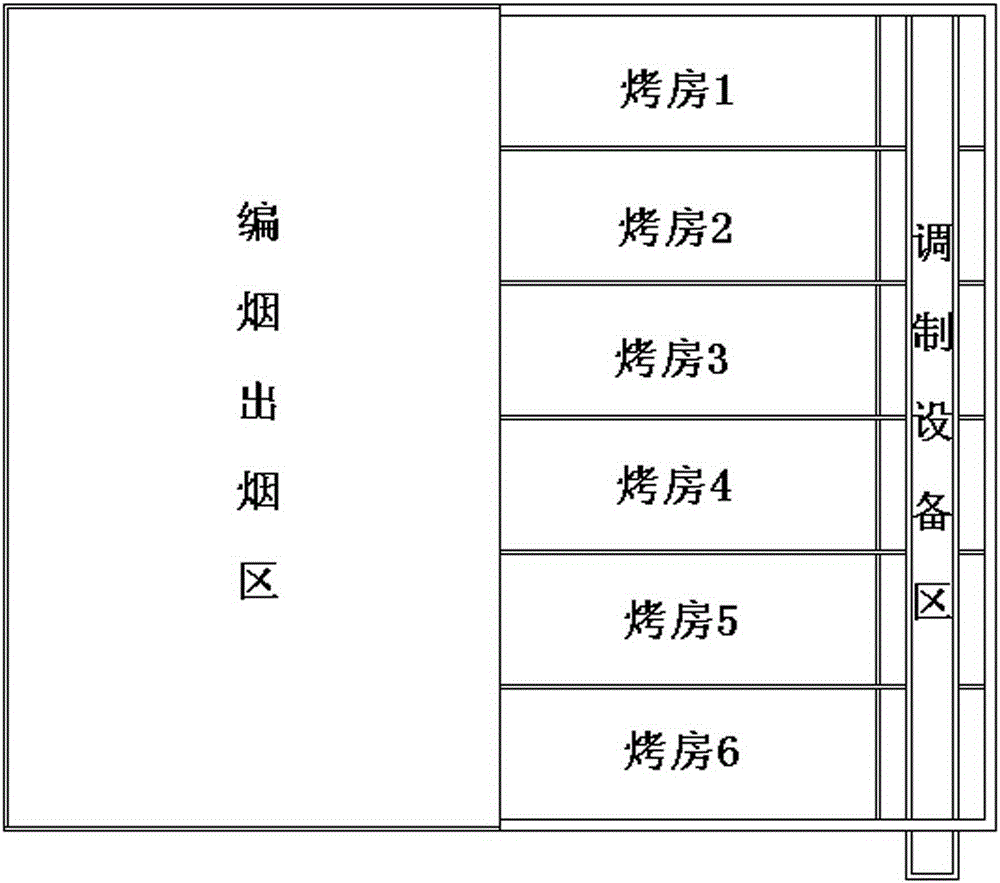

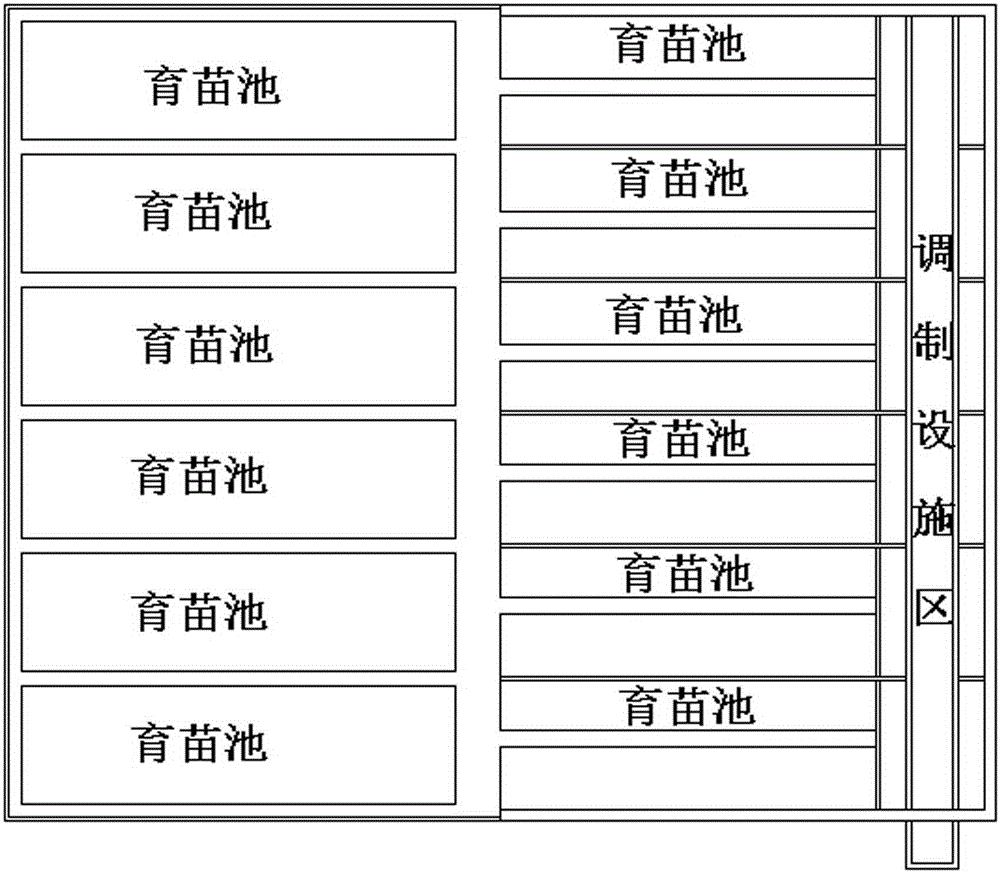

Tobacco leaf curing room modulation equipment and flue-cured tobacco nursery facilities share the greenhouse comprehensive system

A technology of modulation equipment and integrated system, which is applied in the field of greenhouse integrated system, can solve the problems of increasing the production cost of tobacco leaves, and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The embodiments of the present invention are only used for explaining the present invention, and should not be construed as limiting the present invention.

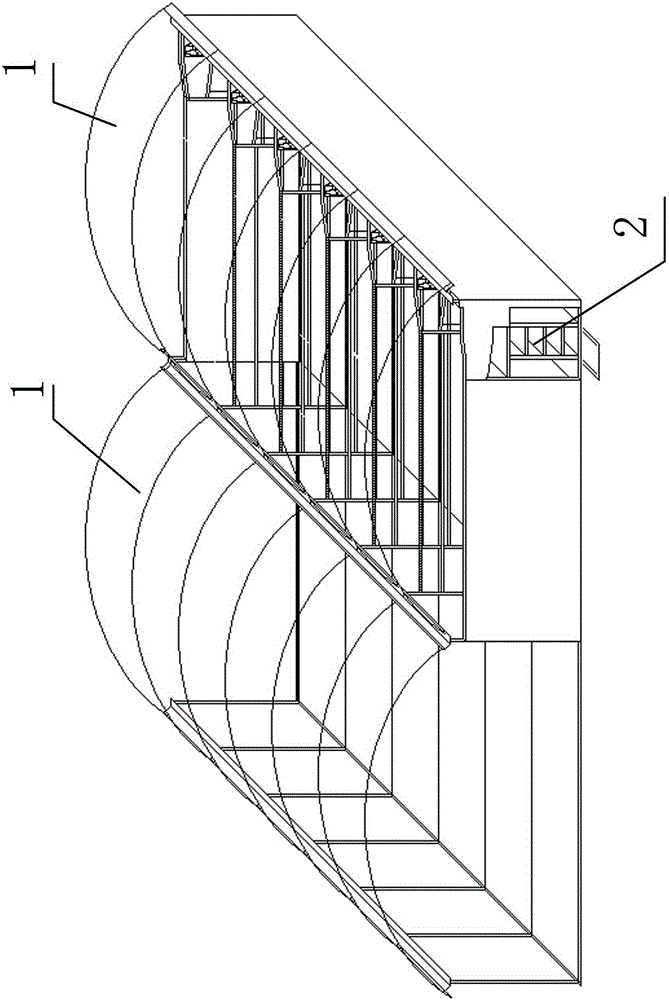

[0047]The shared greenhouse comprehensive system of the present invention consists of a set of centralized heaters, a set of temperature control and humidity control system, a set of power supply system, a spare generator, several pieces of software heat insulation and heat insulation materials, several pipe frames and several pieces It is composed of soft thermal insulation and shading materials, in which the power supply system and the backup generator are connected to the temperature control and humidity control system, and the temperature control and humidity control system controls the heating and ventilation of the central heater.

[0048] The greenhouse frame is composed of several pipe frames connected to each other. The top of the greenhouse frame is covered with soft thermal insulation and light-shielding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com