Glass fiber filter material and preparation method therefor

A technology of filter material and glass fiber, applied in the field of glass fiber filter material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the present invention will be described in detail below in conjunction with specific embodiments, but are not limited thereto.

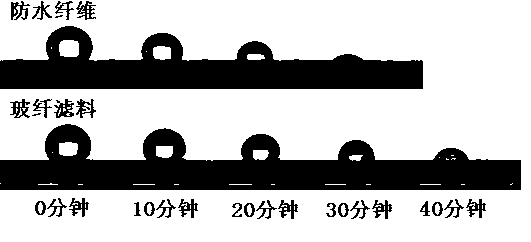

[0018] A glass fiber filter material, with glass fiber cloth as a carrier, a foam coating is arranged inside and outside the glass fiber cloth, there are bubble holes in the foam coating, and the diameter of the bubble holes is 2 ~17 microns. Because the pore size of the bubble hole is very small, more than 1000 times that of gaseous water molecules, and more than 200 times smaller than that of liquid water, water droplets and dust cannot pass through the foam coating, which can achieve effective waterproof and dust removal effects.

[0019] The specific production process is:

[0020] ——Production of glass fiber cloth: the glass fiber is drawn and warped, and then the cloth is woven by a loom, and then dewaxed and thermally cleaned to obtain a glass fiber cloth;

[0021] ——PTFE impregnation: put glass fiber cloth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com