A High Speed and Accurate Automatic Sorting Method

An automatic sorting and accurate technology, applied in sorting and other directions, can solve problems such as human error, a large number of operators, and low efficiency, and achieve the effect of accurate sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

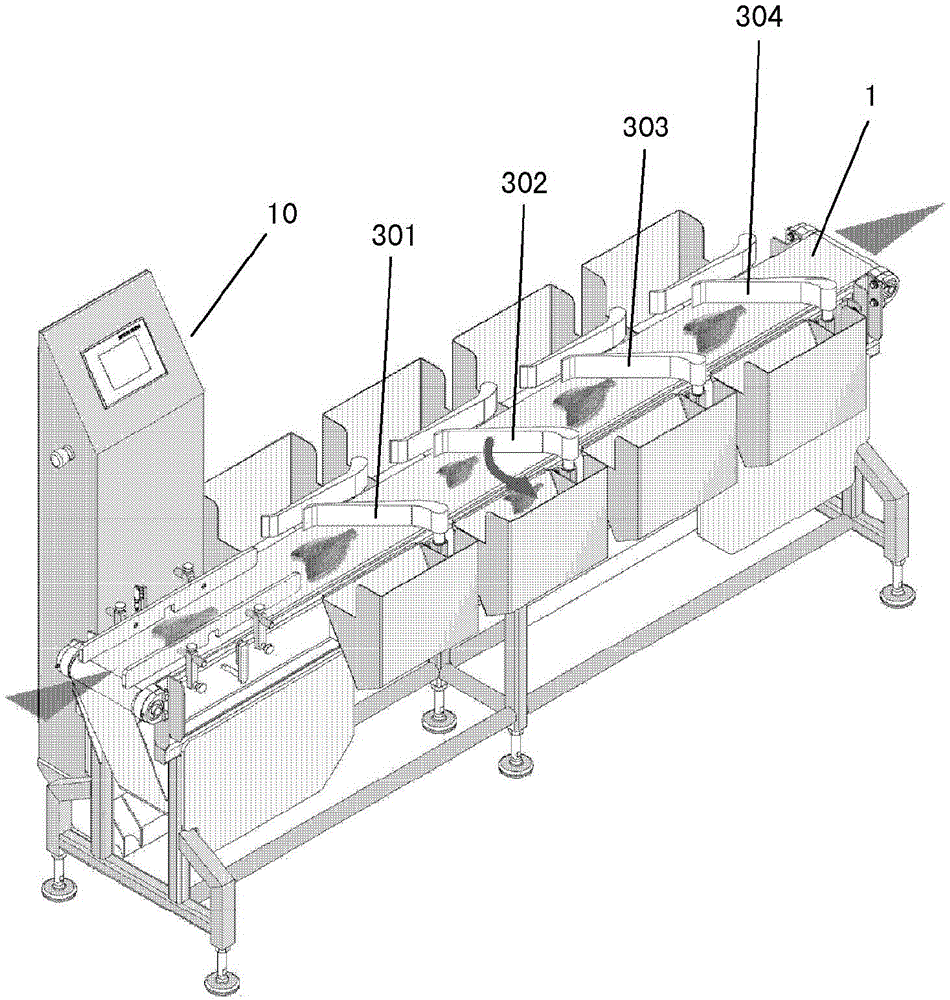

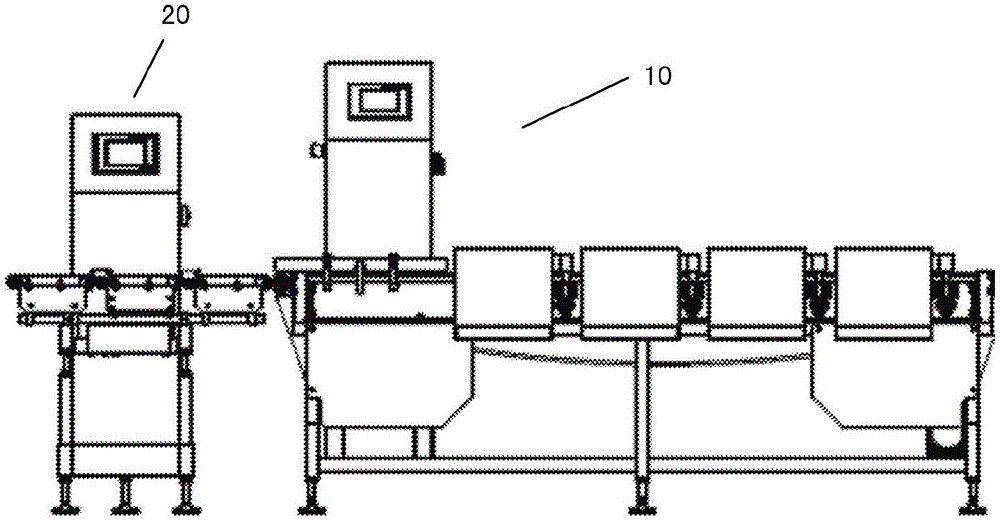

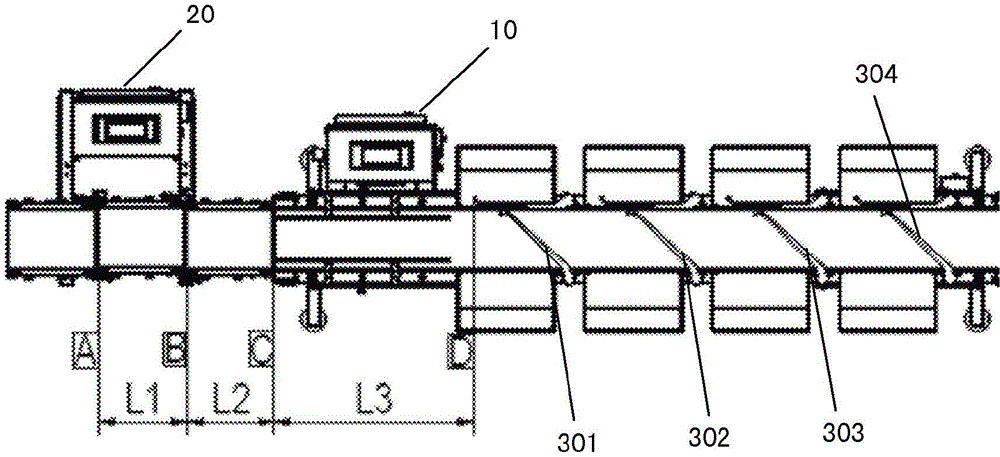

[0025] See figure 1 , shown in 2, this method is applied on the equipment that is spliced by two, namely the checkweigher 20 of front-end and the sorting machine 10 of back-end, and front-end is responsible for weighing, and back-end according to the weight information that is provided by front-end, after calculating, After judging, control the actions of the corresponding rejectors 301-304. Furthermore, the front-end checkweigher 20 is used to detect the weight of the sorted product on the conveyor belt 1 and the information of the photoelectric sensor signal, and sends the weight of the sorted product to the back-end equipment sorter 10 through the communication interface, and the The sorting machine 10 specifically controls which rejecter acts on the sorted products with a weight range, for example, the control rejecter 301 is used to reject the sorted products of 0-10 kg, and the rejecter 302 is aimed at the sorted products of 10-20 kg. The products are rejected, ... In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com