Security inks and machine readable security features

A technology with safety features and safety, applied in the field of safety ink, can solve the problems of low light resistance and production complexity, limited use, low thermal stability, etc., to achieve the effect of easy machine readability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

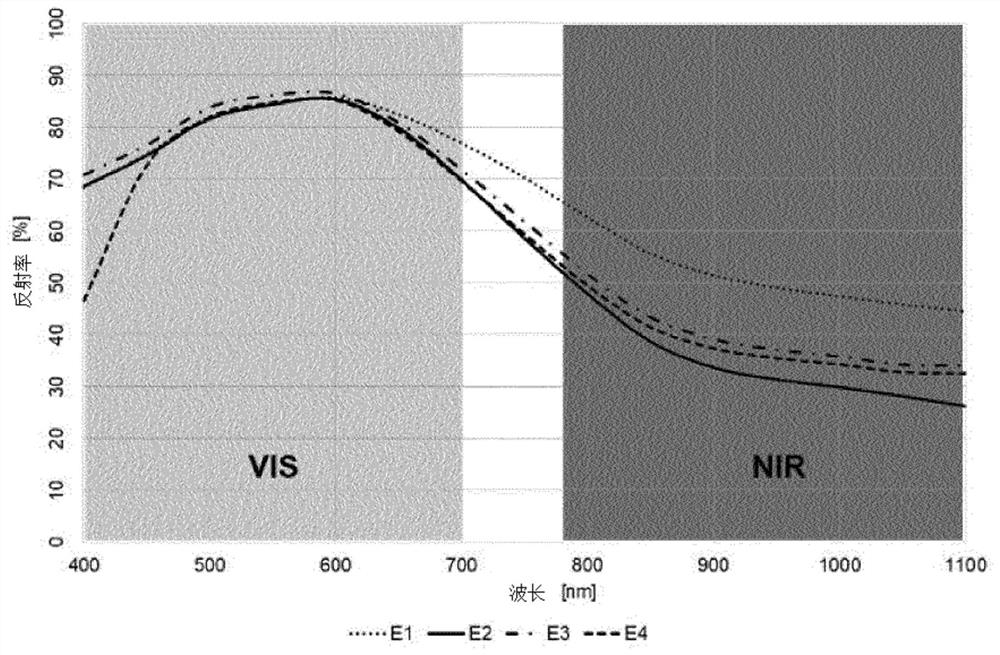

[0127] The invention will now be described in more detail with reference to non-limiting examples. The following examples provide further details of the preparation and use of security inks for printing machine-readable security features, said security inks independently comprising an IR absorbing material composed of a base formula having a phosphorite crystal structure. copper phosphate Cu 2 PO 4 (OH) (CAS-Nr. 12158-74-6) with a particle size d50 of 2.0-2.6 μm and a particle size d98 of 7.5-12.0 μm. Laser diffraction method was used to determine the d50 and d98 values (instrument: (Cilas 1090); sample preparation: IR absorbing material was added to distilled water until the laser photoresistence reached the operating level of 13-15%, and the measurement was carried out according to ISO standard 13320.

[0128] Four security inks have been prepared and applied to substrates:

[0129] a) water-based heat-drying flexographic printing security ink (Example E1),

[0130] b)...

Embodiment E2

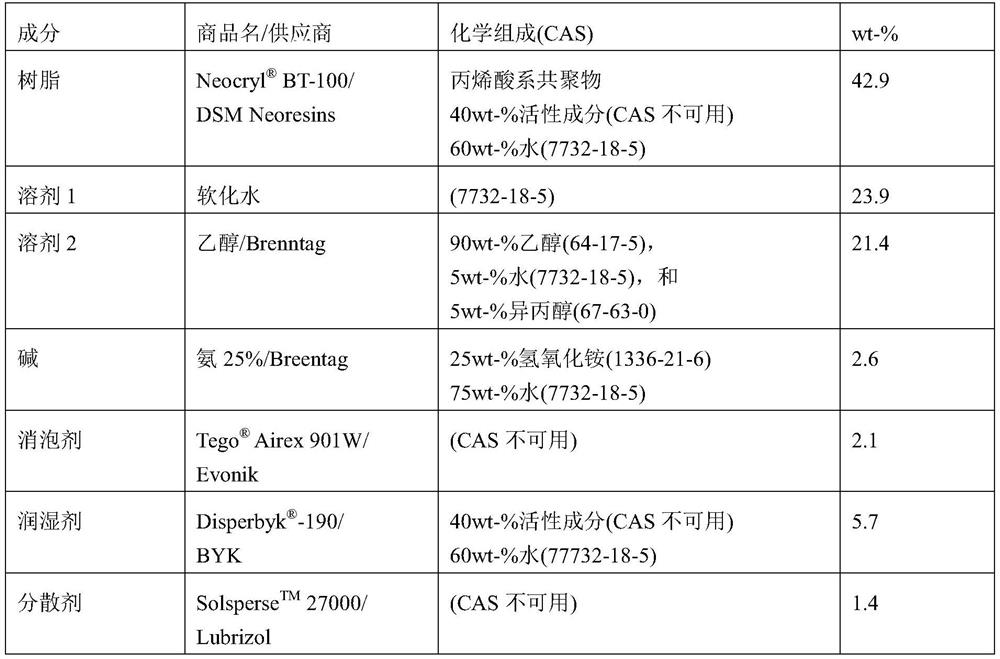

[0146] B.1. Preparation of solvent-based heat-drying rotogravure printing security ink (E2)

[0147] The components of the ink vehicle described in Table 2A were mixed and dispersed at room temperature using a Dispermat (FT) at 2500 rpm for 30 minutes.

[0148] 300 g of the IR absorbing compound basic copper phosphate was added to the ink carrier 700 g described in Table 2A and dispersed at 1500 rpm for 10 minutes to obtain 1 kg of heat-drying rotogravure security ink E2 described in Table 2B.

[0149] The viscosity values provided in Table 2B were measured with a Brookfield viscometer (model "RVDV-I Prime", spindle 21 at 100 rpm) at 25°C on approximately 15 g of safety ink.

[0150] Table 2A

[0151]

[0152] Table 2B

[0153] security ink Ink carrier described in Table 2A IR absorbing compound Viscosity at 25°C and 100rpm E2 70wt-% 30wt-% 114mPa s

[0154] B.2. Preparation of printed machine-readable security features with solvent-ba...

Embodiment E3

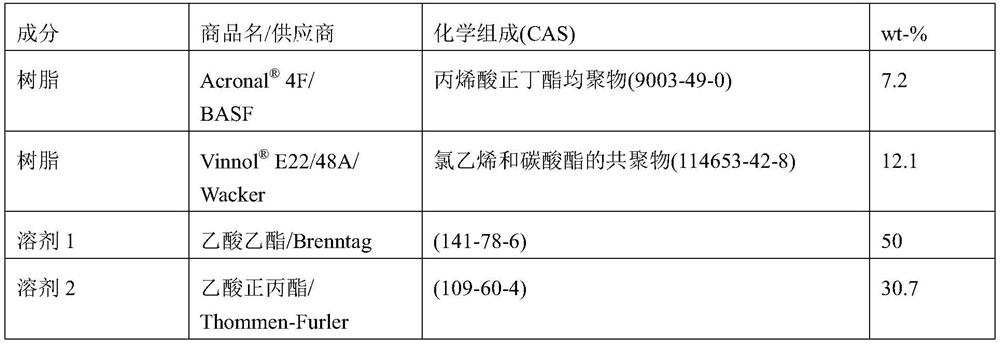

[0157] C.1. Preparation of solvent-based heat-drying screen printing security ink (E3)

[0158] The ingredients of the ink vehicle described in Table 3A were mixed and dispersed at room temperature using a Dispermat (FT) at 1000 rpm for 15 minutes.

[0159] 120 g of an IR absorbing compound basic copper phosphate was added to 880 g of the ink carrier described in Table 3A, and dispersed at 1200 rpm for 10 minutes, thereby obtaining 1 kg of heat-drying screen printing security ink E3 described in Table 3B.

[0160] The viscosity values provided in Table 3B were measured at 25°C with a Brookfield Viscometer (Model "RVDV-I Prime", spindle 27, at 100 rpm) on approximately 15 g of safe ink vehicle.

[0161] Table 3A

[0162]

[0163] Table 3B

[0164] security ink Ink carrier described in Table 3A IR absorbing compound Viscosity at 25°C and 100rpm E3 88wt-% 12wt-% 1350mPa s

[0165] C.2. Preparation of printed machine-readable security feat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com