Multi-station automobile aluminum alloy profile bending and punching system

An aluminum alloy profile, multi-station technology, applied in the field of punching systems, can solve problems such as complex dimensions and achieve the effect of accurate hole position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further explained below in conjunction with the drawings and embodiments, but the following content is not intended to limit the protection scope of the present invention.

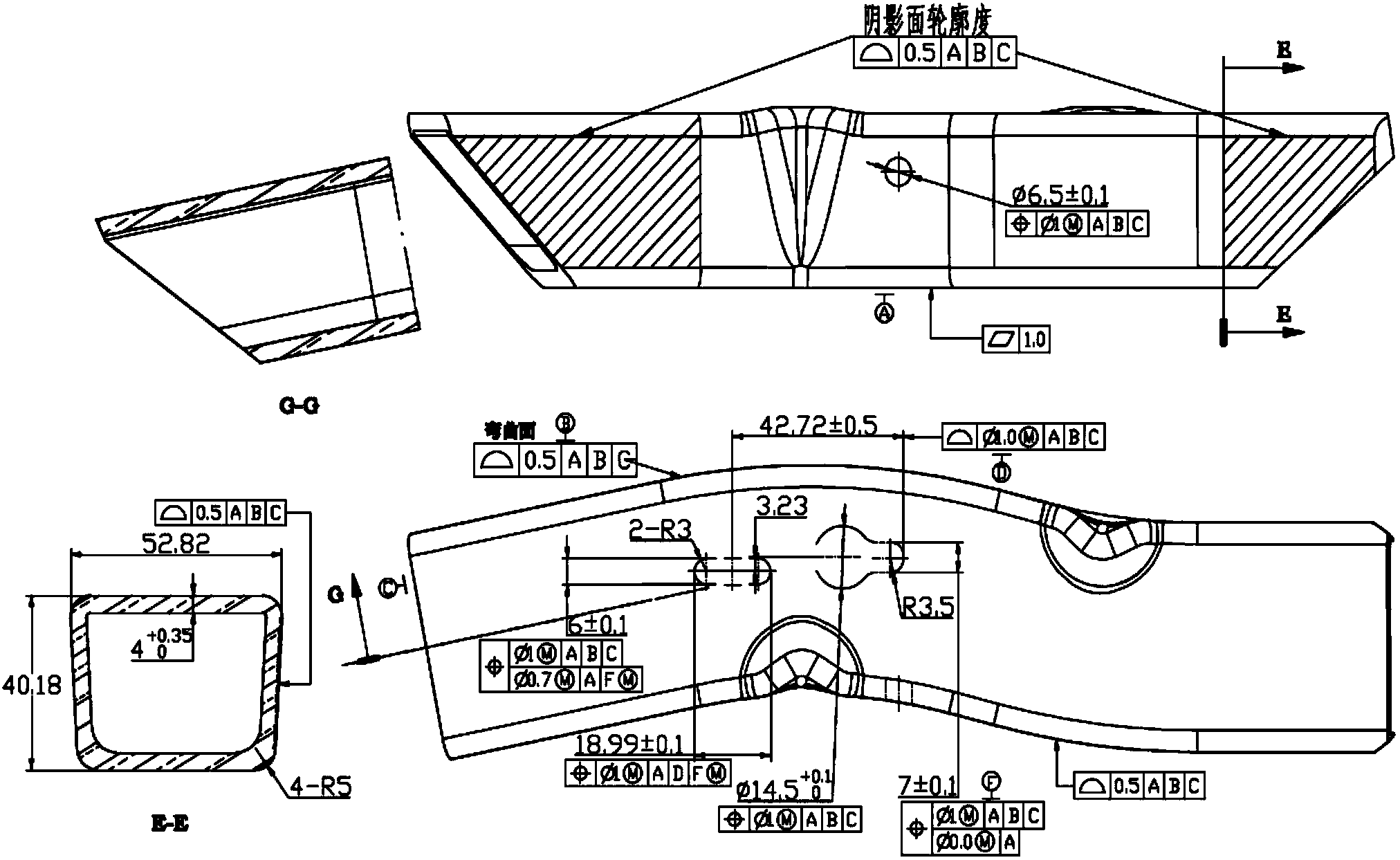

[0033] Such as figure 1 As shown, it is a schematic diagram of the workpiece processed in this embodiment. The material of the blank aluminum profile 6 is 6061T6, the thickness is 4mm, and the length is 245mm. .5 special-shaped hole, there is a ¢6.5 on the upper part, the specific hole tolerance and position are as follows figure 1 shown. Compared with the same type of products, the product profile and position requirements are higher, and the profile of the shadow surface and curved surface is as follows: figure 1 As shown, the product size is more complicated.

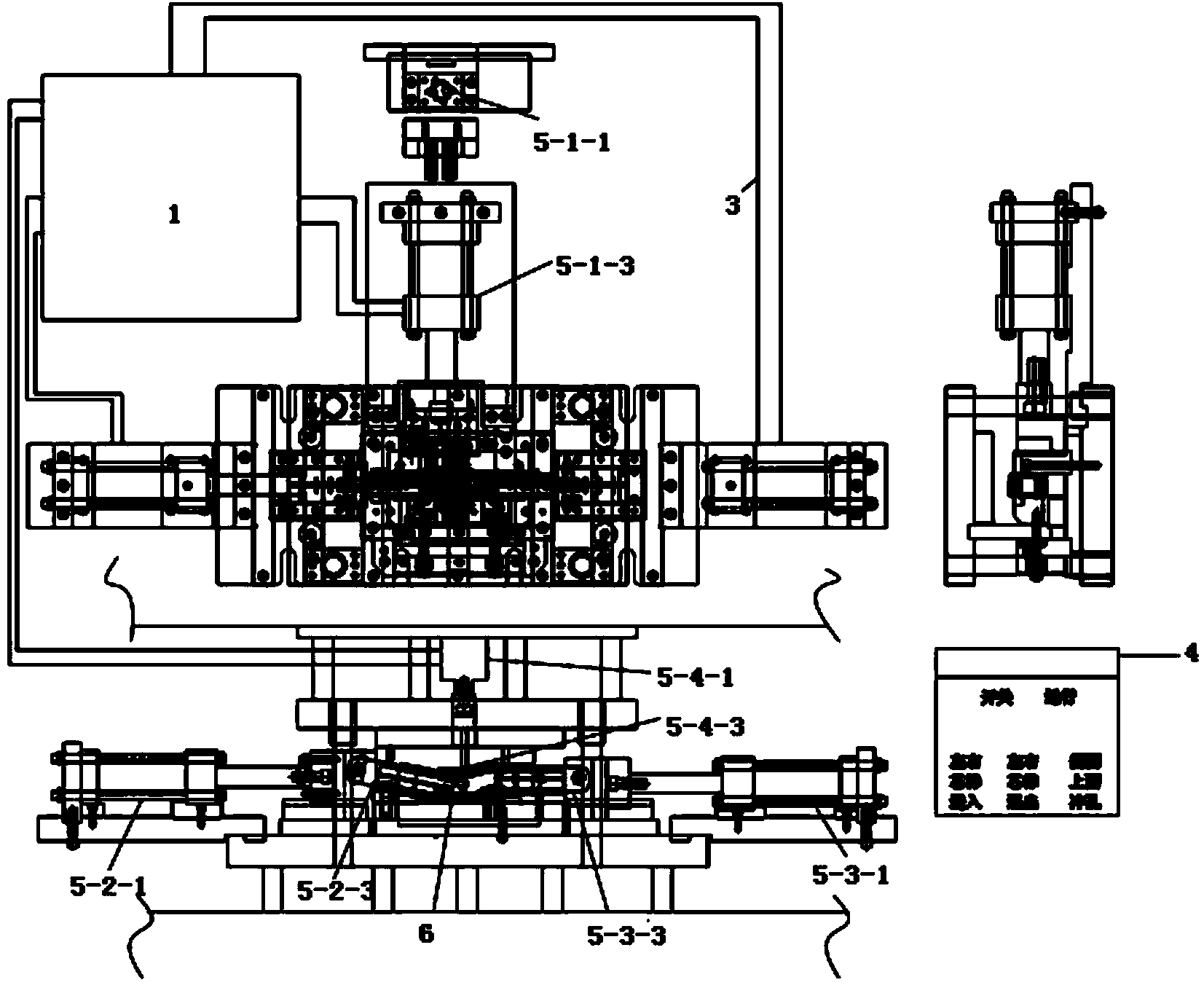

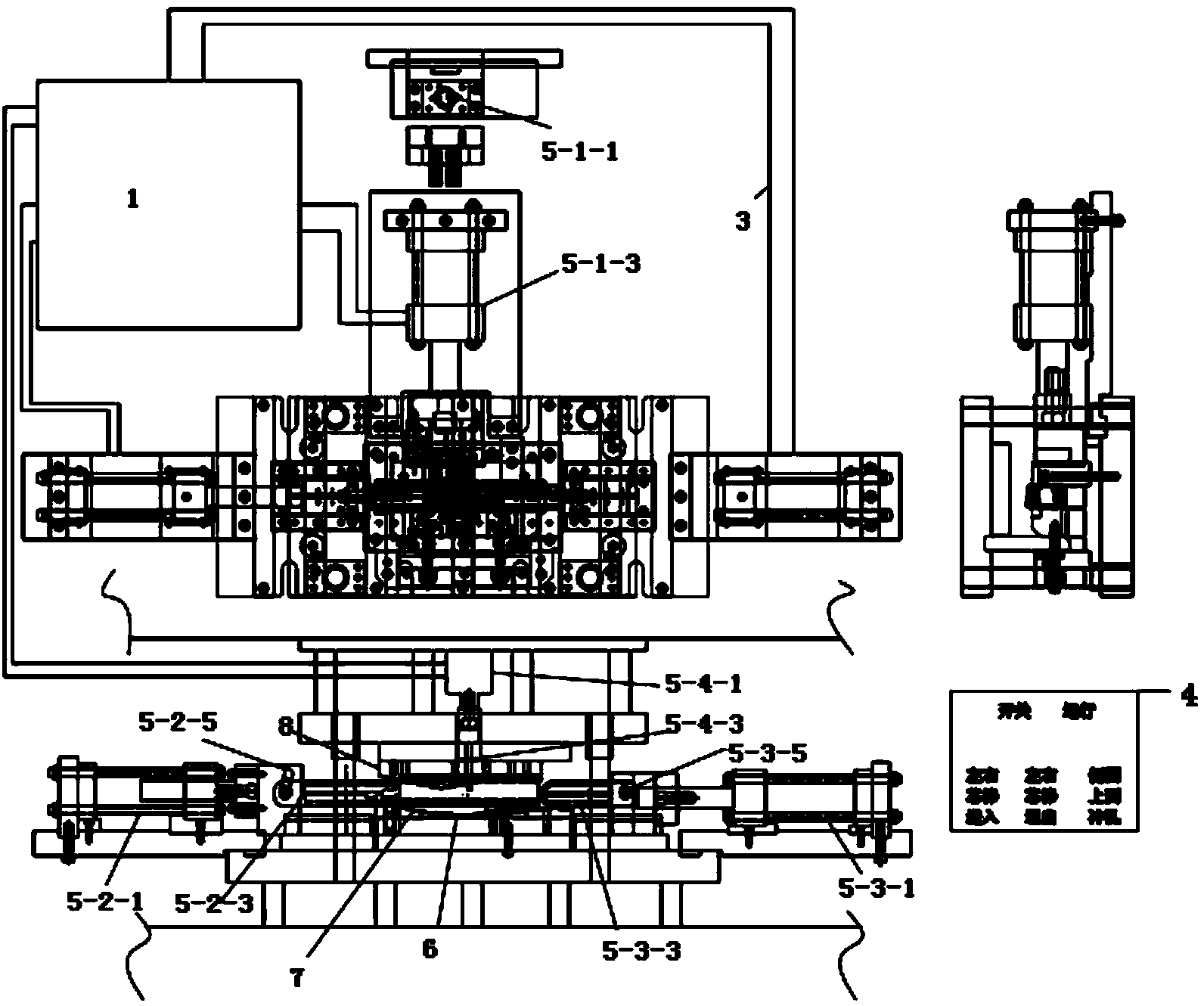

[0034] Such as Figure 2-Figure 8 As shown, this embodiment provides a multi-station automotive aluminum alloy profile bending and punching system, including a hydraulic station ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com