Radio frequency/microwave blind-mate connector array positioning method

A positioning method and connector technology, which is applied in the direction of connection, assembly/disassembly of circuit/collector components, contact pieces, etc., to achieve the effects of facilitating equipment assembly, improving assembly quality, and shortening assembly adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

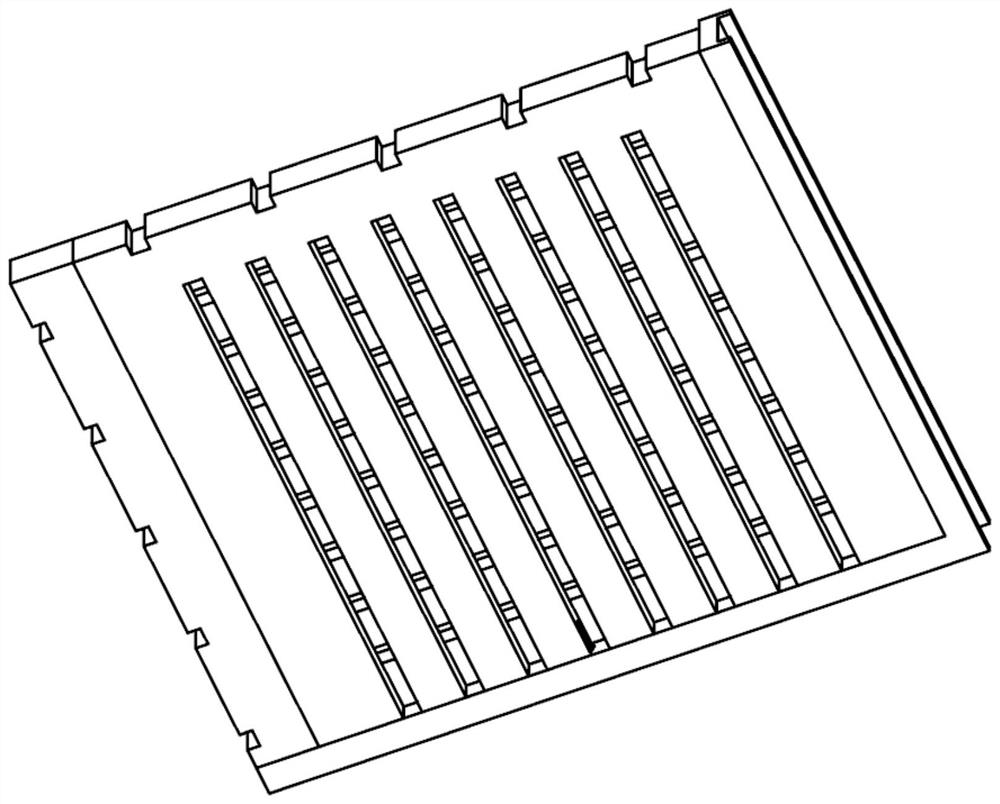

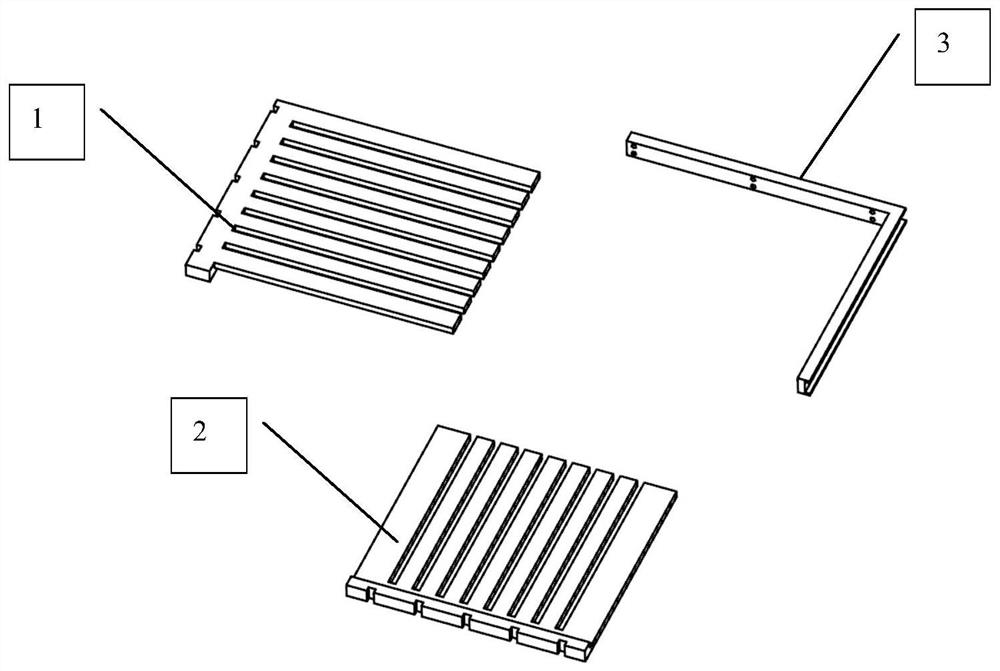

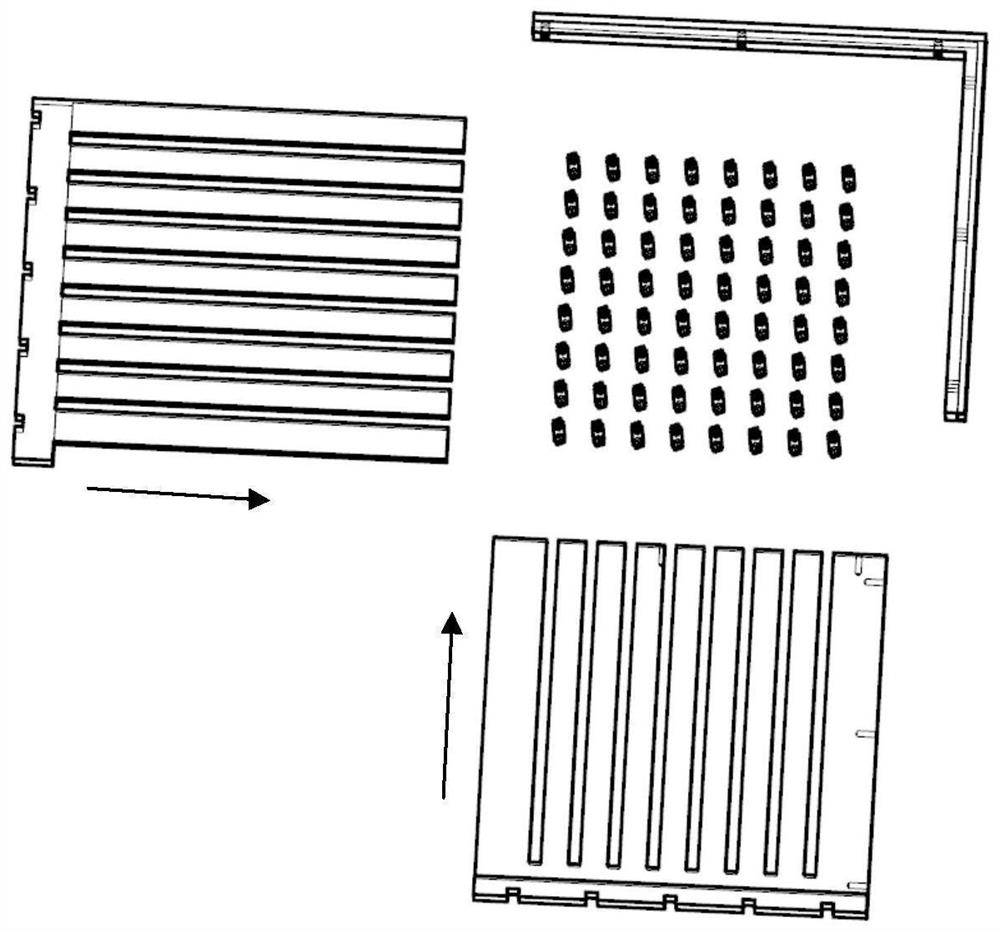

[0020] refer to Figure 1-Figure 5 . According to the present invention, first prepare a finger-shaped fixture that can limit the two-way plugs of all radio frequency blind mating connector arrays in the vertical and horizontal intersecting finger grids of two sets of positioning finger boards; then when assembling, first connect the radio frequency blind mating All array bidirectional plugs of the device are inserted one by one into the socket blind-matching jack of one of the microwave component modules to form a matrix of radio frequency bidirectional plug arrays; Two directions are cross-inserted into the array area of the RF bidirectional plug, and two sets of vertically and horizontally stacked positioning fingers form an intersecting grid between the matrix rows and columns of the RF bidirectional plug; 1 and the horizontal positioning finger board 2 are intersected to form a rectangular right-angled side; each hole in the grid of the two sets of positioning finger b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com