Circular cutting saw stress end jumping detecting correcting machine

A dicing saw and calibrating machine technology, which is applied in the measurement, measuring device, metal sawing equipment and other directions by measuring the changing force of the optical properties of the material when it is under stress, can solve the problems of unusable measuring device and low efficiency, etc. The effect of smooth pressure, improved measurement accuracy, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

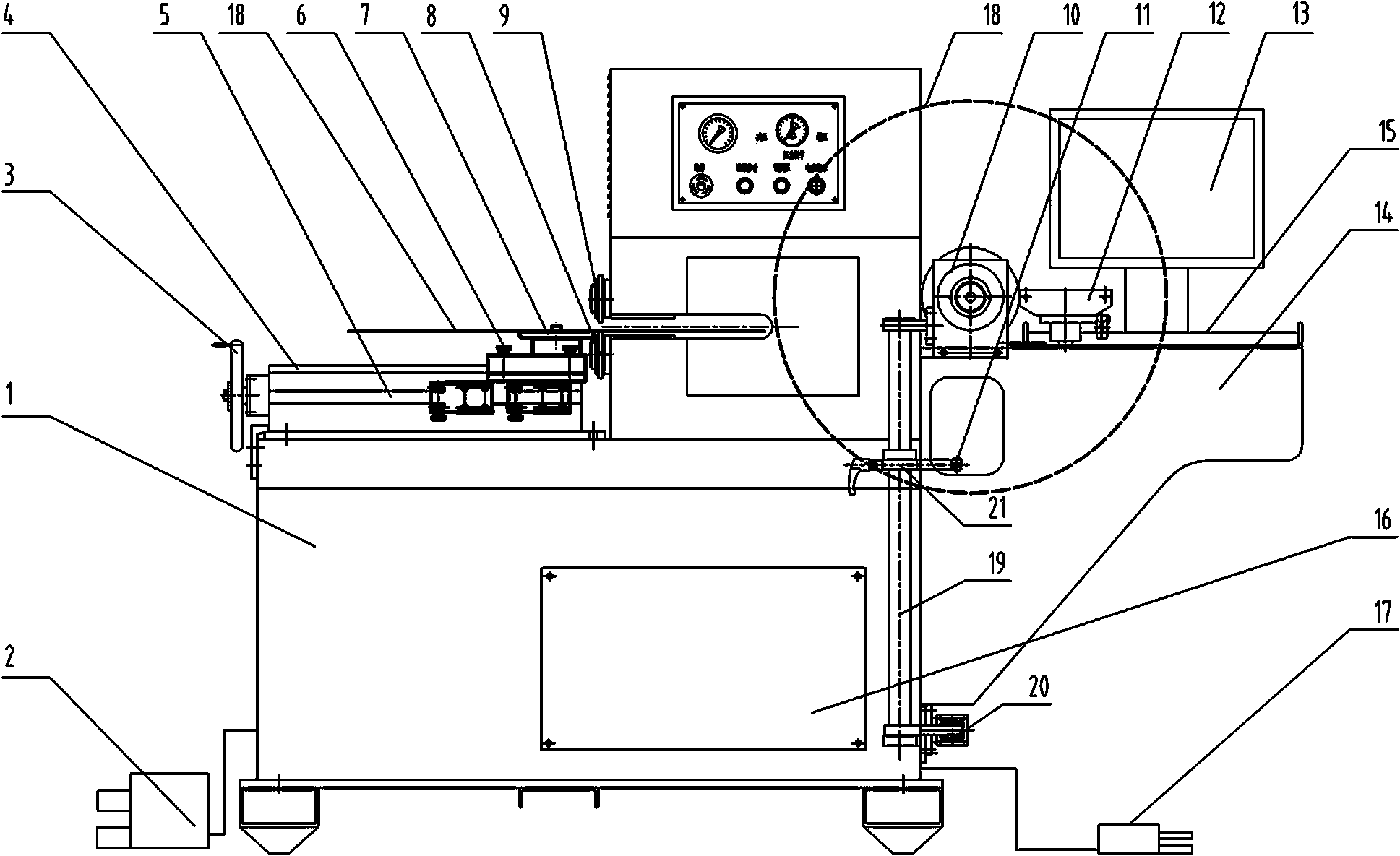

[0020] Such as figure 1 Among them, a circular cutting saw stress end jump detection and correction machine includes a frame 1, a hydraulic station 16 and an air pressure control cabinet 14 are arranged on the frame 1, a main control computer 13 is also provided, and a roller is installed at one end of the frame 1. Pressure device, the other end is equipped with tension measurement, end jump measurement device. Two ends of the frame 1 are provided with a foot-operated rolling switch 2 and a pneumatic switch 17 .

[0021] In the described rolling device, the rolling seat 7 is movably installed on the guide rail 4, the axis of the rolling seat 7 is perpendicular to the horizontal plane, and one side of the rolling seat 7 is provided with a matching rotating rolling wheel 8 and a compacting roller. Pressing wheel 9, rotating rolling wheel 8 is connected with the device that drives it to rotate, and pressing rolling wheel 9 is connected with the oil cylinder that drives it to mov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com