A spark spectrum excited electrode repair device and method

A technology of exciting electrodes and repair methods, which is applied in the field of inspection and testing equipment, can solve problems affecting the accuracy of spectrometer analysis results, differences in spectrometer analysis capabilities, and decline in spectrometer analysis capabilities, so as to improve operating efficiency and spectrometer utilization and shorten repair time , The effect of eliminating the influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

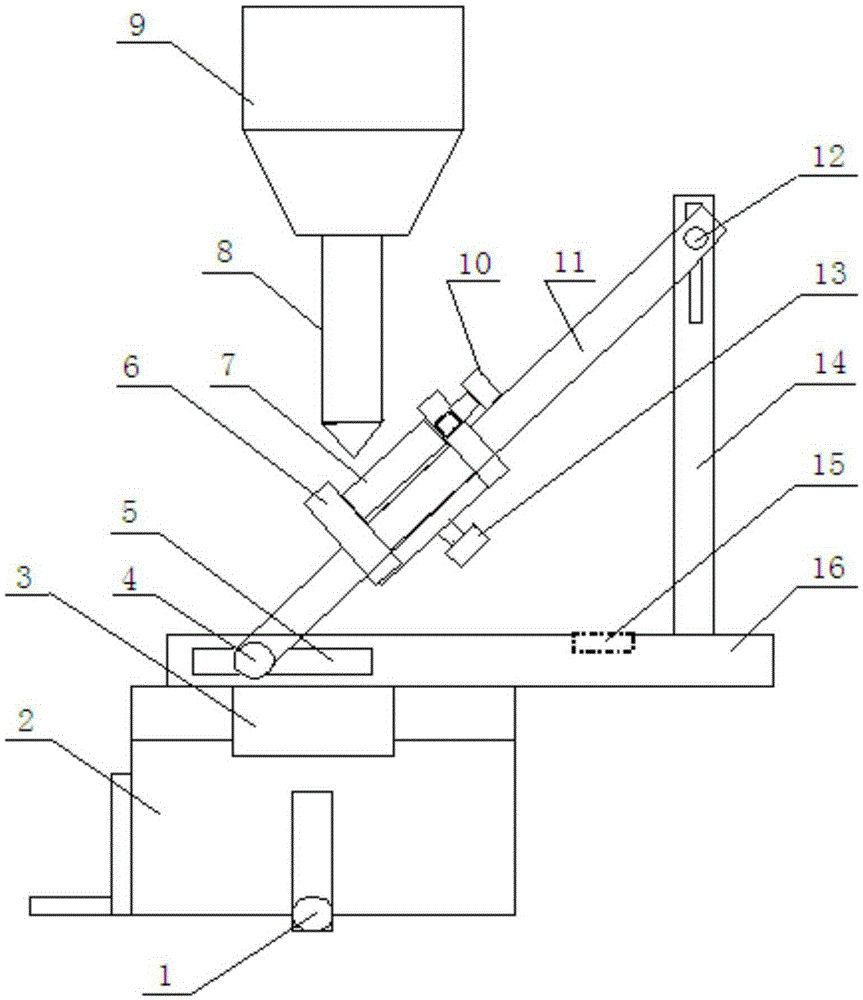

[0020] Depend on figure 1 It can be seen that the spark spectrum excitation electrode repairing device of the present invention is mainly composed of vise 2, drill press holder 9 and repair frame, that is, on the basis of the original vise 2 and drill press holder 9, an additional installation is installed on the vise 2 A set of repair racks.

[0021] The repair frame is triangular as a whole, and is composed of fixed seat 3, adjusting bolt 4, clamp 6, plate file 7, diagonal brace 11, bearing pin 12, column 14, spirit level 15 and base plate 16. The fixture 6 is "U" shaped, and two splints with holes are connected together through the connecting plate, and a fixing screw 13 is threaded on the connecting plate to fix the fixture 6, and a locking screw 10 is threaded on the upper splint , in order to fix the board file 7. The bottom plate 16 is a rectangular flat plate, on the upper surface of the flat plate is processed a section of chute for the movement of the diagonal brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com