A new type of vegetable cutter and its control method

A vegetable cutting machine, a new type of technology, applied in the direction of metal processing, etc., can solve the problems of limited working capacity, high speed, time-consuming manual cutting of vegetables, etc., and achieve the effect of high production efficiency and fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

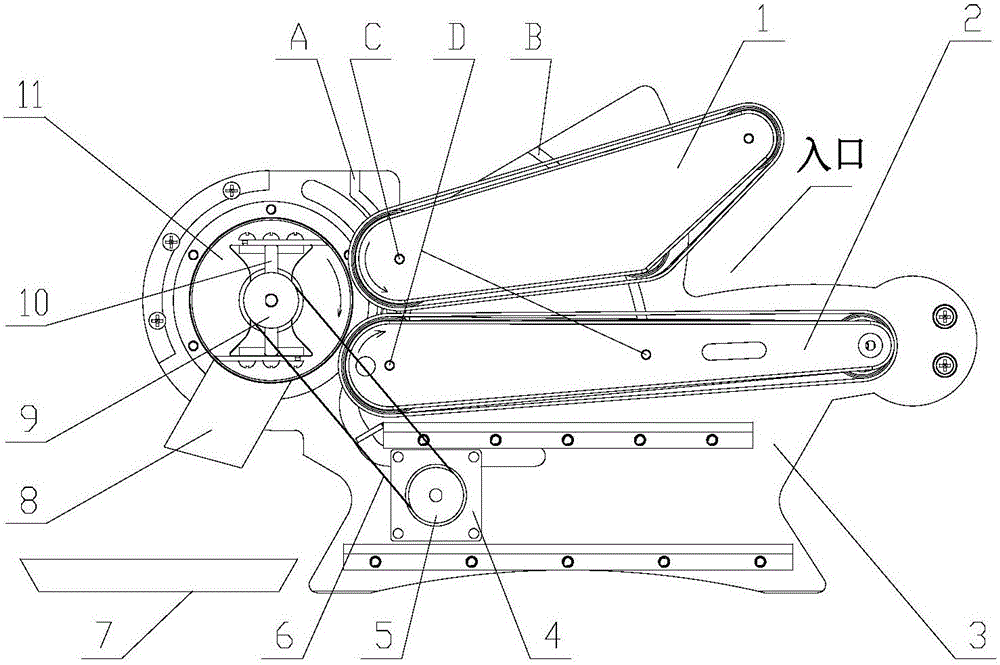

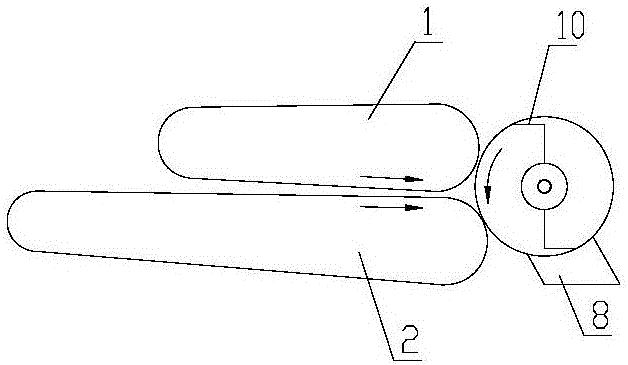

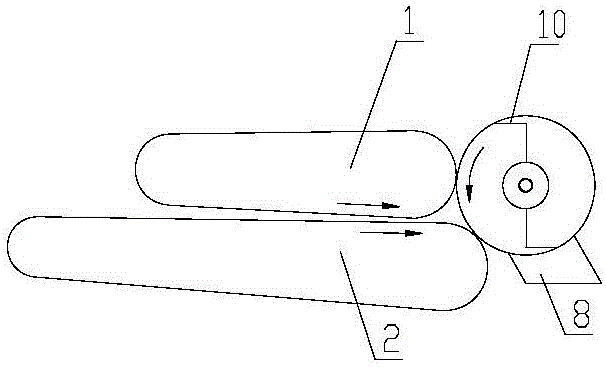

[0045] The structure of the novel vegetable cutting machine of the present invention includes a belt feeding part and a rotating cutter, the material output end of the belt feeding part corresponds to the entrance of the cutting chamber where the rotating cutter is located, and the belt feeding part is composed of one belt conveyor or two or more belt conveyors. When the belt feeding part includes an upper belt conveyor and a lower belt conveyor, the upper belt conveyor and the lower belt conveyor are respectively built with driving motors, and the cutter is driven by the main motor installed on the frame through the timing belt. The upper belt conveyor and the lower belt conveyor are located outside the rotation circle of the tool, and the upper belt conveyor and the lower belt conveyor are installed separately or combined freely according to the needs of use. Both the upper belt conveyor and the lower belt conveyor have projections protruding from the sides on both sides, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com