Hot nozzle main body

A technology of hot nozzle and main body, which is applied in the field of hot nozzle main body, can solve the problems of uneven heating of molten materials, slow down the heating speed of hot nozzle, and the number of heating wire turns, so as to improve the unsmooth glue discharge, improve work efficiency, The effect of increasing the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

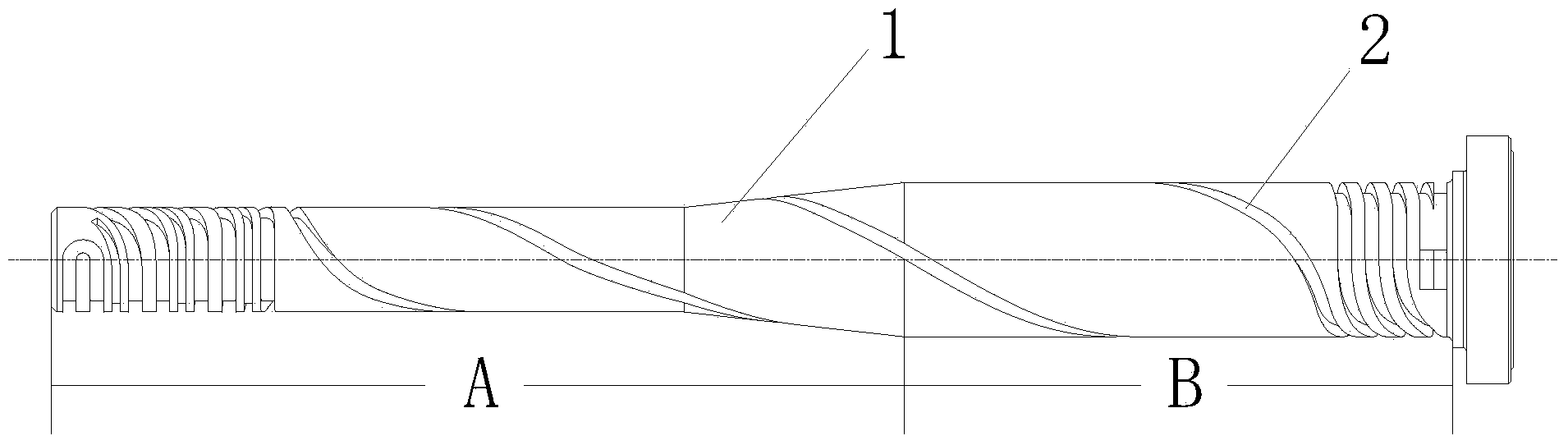

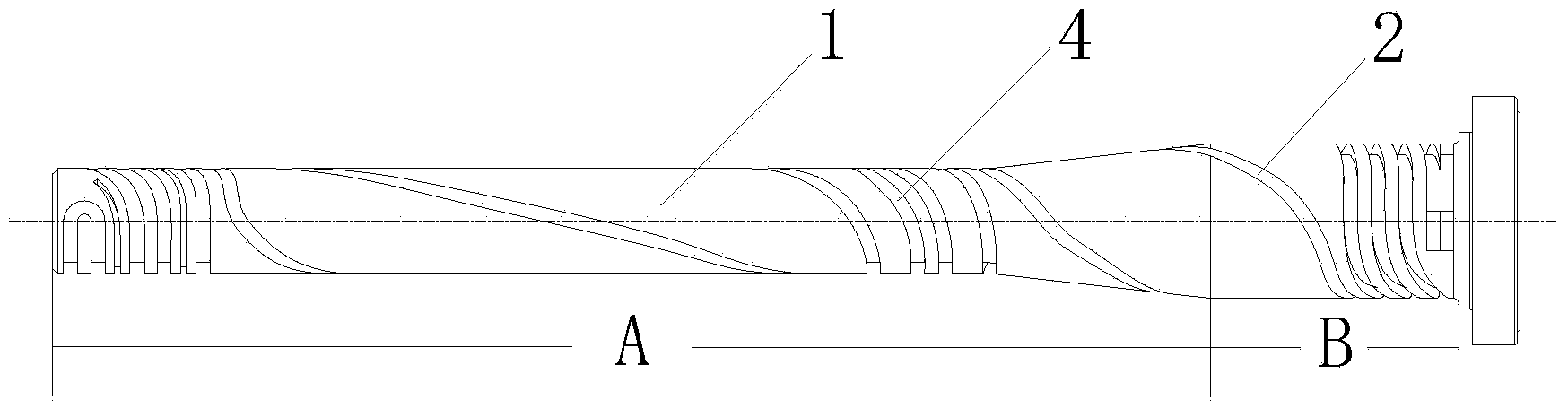

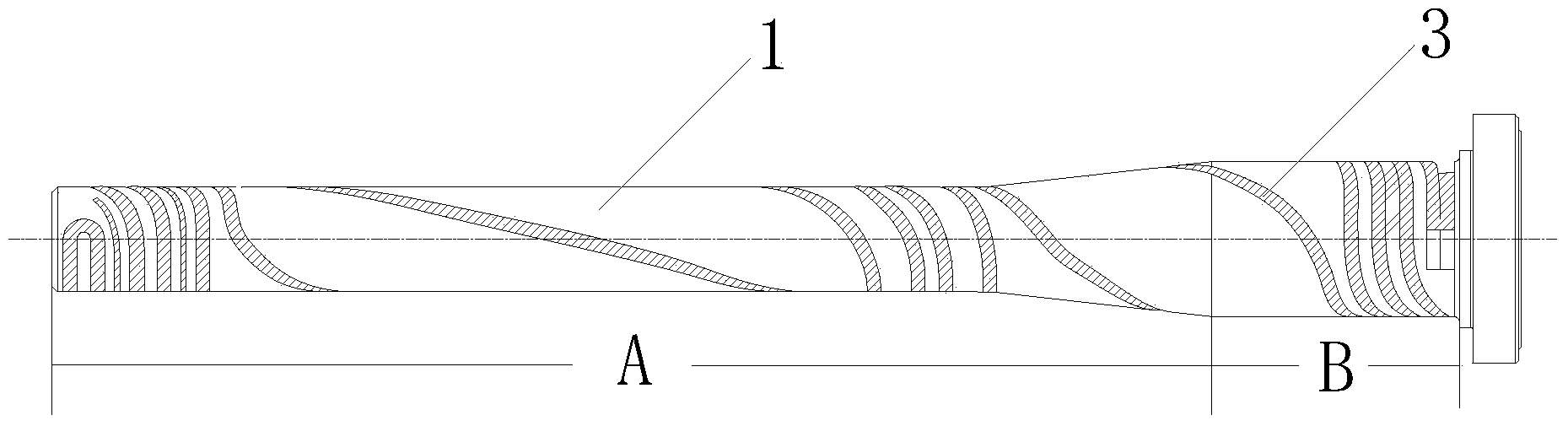

[0013] attached figure 2 , 3 It is a hot nozzle body according to the present invention, including a hot nozzle body 1, a groove 2, and a heating wire 3; the groove 2 is spirally arranged on the outer circumference of the hot nozzle body 1, and the inside of the groove 2 A heating wire 3 is wound; the nozzle body 1 includes a small-diameter section A and a large-diameter section B; the rear end of the small-diameter section A is set at the front end of the large-diameter section B; the small-diameter section The length of the nozzle is at least 4 / 5 of the length of the hot nozzle; an encrypted groove is added on the section A of the small-diameter part near the rear end, the groove density is at least 2.5 turns / cm, and the heating wire is wound in the encrypted groove 4 3.

[0014] Due to the application of the above-mentioned technical solution, the present invention has the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com