Method for strengthening antiskid performance of antiskid nail core and antiskid nail core

A technology of anti-skid performance and anti-skid studs, which is applied in tire tread/tread pattern, tire parts, transportation and packaging, etc. It can solve the problems of anti-skid stud core slippage, achieve the effect of preventing wheel slipping and improving anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

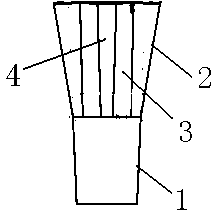

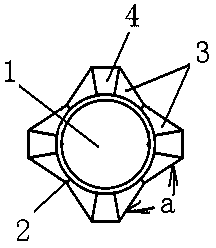

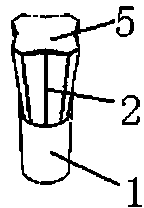

[0036] Such as Figure 1-3 As shown, a two-stage structure anti-skid stud core includes an anti-skid stud core body 1 and an anti-skid stud core cap 5, and the anti-skid stud core body 1 is a cone structure, and its feature is that the anti-skid stud core body is two Segment structure; one section is a cone, the other is a quadrangular cone; and the taper of the cone and the quadrangular cone are two different tapers; wherein, the taper of the cone is 2-3 degrees, and the taper of the quadrangular cone is 4-6 degrees. The quadrangular cone of the anti-skid stud core is connected to the cone, and the taper of the quadrangular cone is larger than that of the cone. The polygonal cone of the anti-skid stud core is a quadrangular cone. The quadrangular shape of the quadrangular cone of the anti-skid stud core is composed of four protruding frustum blocks, and the four protruding frustum blocks are protrusions that incline from top to bottom and gradually shrink inward, forming A...

Embodiment 2

[0039] Such as Figure 4-5 As shown, a two-stage structure anti-skid stud core includes an anti-skid stud core body and an anti-skid stud core cap, and the anti-skid stud core body is a cone structure, and its feature is that the anti-skid stud core body is a two-stage structure; One section is a cone, and the other section is a pentagonal cone; and the taper of the cone and the pentagonal cone are two different tapers; among them, the taper of the cone is 1-1.5 degrees, and the taper of the pentagonal cone is 3-5 Spend. The pentagonal cone of the anti-skid stud core is connected to the cone, and the taper of the pentagonal cone is greater than the taper of the cone. The pentagonal cone of the anti-skid stud core is a pentagonal cone. The pentagonal shape of the pentagonal cone of the anti-skid stud core is composed of five protruding frustum blocks, and the five protruding frustum blocks are all protruding blocks that incline from top to bottom and gradually shrink inward, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com