Forward and reverse differential transmission mechanism and drug bottle delivery device

A differential transmission, forward and reverse technology, applied in the field of transmission devices for packaging machines, can solve the problems of difficulty in adjusting the rotational speed and frequency of the driving roller, uneven stacking of the forward and reverse motors, and increased use costs, so as to achieve easy maintenance and use. , the effect of saving labor, reducing use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

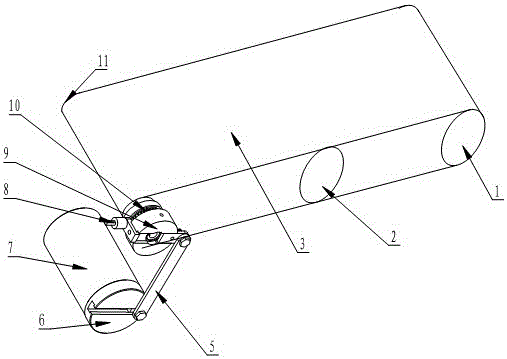

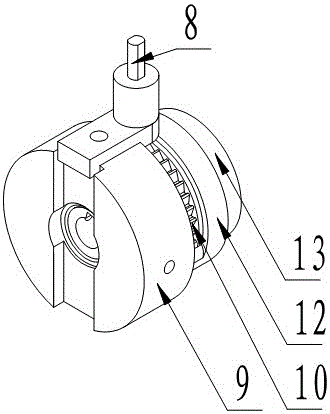

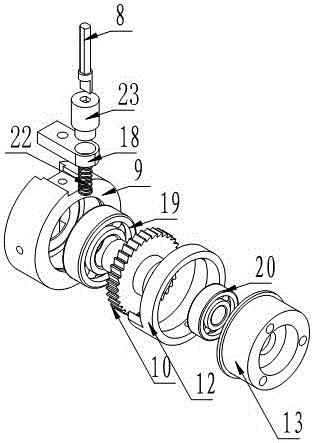

[0042] Embodiment 1 A forward and reverse differential transmission mechanism, see Figure 1 to Figure 10 , figure 2 image 3 and Figure 9 , Figure 10 The main shaft is omitted in the above, a forward and reverse differential transmission mechanism, including a main shaft, a ratchet 10 mounted on the main shaft and a ratchet fixing assembly corresponding to the teeth of the ratchet, an outer bearing installed at the input end of the main shaft and Its matching bearing sleeve 9, the inner bearing and its bearing cover 13 installed on the output end of the main shaft, the outer bearing is an overrunning clutch 19, and the ratchet fixing assembly is fixedly connected to the ratchet fixing rod 18 through the corresponding ratchet fixing rod On the bearing sleeve 9, the direction in which the ratchet fixing assembly drives the ratchet wheel 10 to rotate intermittently is opposite to the direction in which the main shaft is driven to rotate when the overrunning clutch 19 is on...

Embodiment 2

[0056] Embodiment 2 A bottle packaging machine transmission device, the principle of this embodiment is the same as that of Embodiment 1, the difference is that the ratchet 10 is replaced by a matching friction wheel, and the tooth shape of the ratchet 8 is an ellipse corresponding to the friction wheel shaped sector.

[0057] This embodiment is slightly less stable in production, but more convenient for maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com