Numerical controllable scissor mechanism and its composite scissor mechanism driving system

A technology of scissor mechanism and driving system, which is applied in the direction of hoisting device, lift frame, etc., can solve the problems of small expansion ratio, small load capacity, inaccurate terminal positioning, etc., achieve large expansion ratio, improve load capacity and stability, Accurate effect of telescopic positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

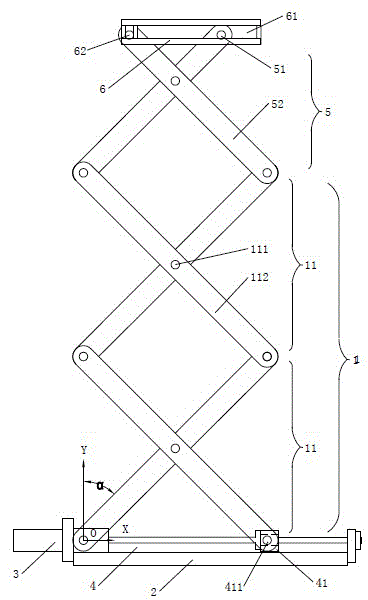

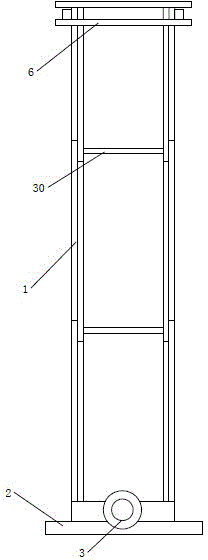

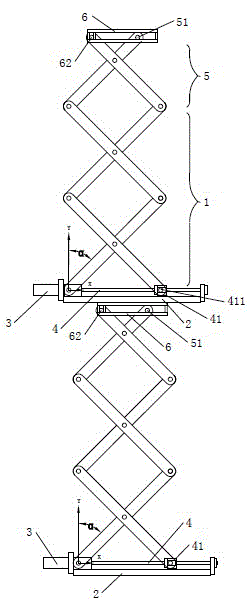

[0018] The present invention is a numerically controllable scissor mechanism, such as figure 1 , 2 As shown, it includes a bracket unit 1, a frame 2, a CNC motor 3 installed on the frame 2, and a ball wire driven by the CNC motor 3, which are hinged at least two pairs of crossed scissor brackets 11 at the ends in turn. Rod 4, one end of the bottom of the pair of scissor brackets 11 at the bottom of the bracket unit 1 is hinged on the base 2 as the origin O, and the other end is hinged on the nut 41 of the ball screw 4; the ball screw 4 and The bracket units 1 are parallel or coincident in a plan view direction. In this embodiment, there are two sets of bracket units, and each of their corresponding hinge points is synchronously connected through the connecting shaft 30, such as figure 1 , 2 As shown, this structure is often applied in the current scissor mechanism. like figure 1 As shown, each support unit 1 has two pairs of scissor supports 11 .

[0019] When the CNC mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com