Application of Br phi nsted acid ion liquid to preparation of diphenyl oxalate

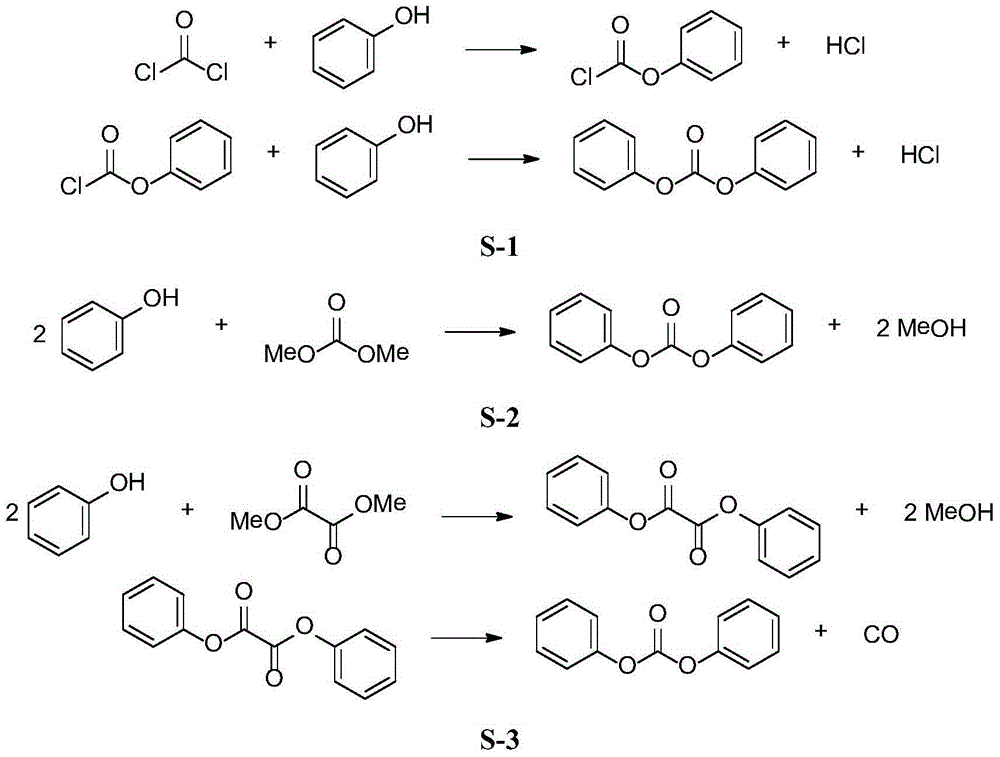

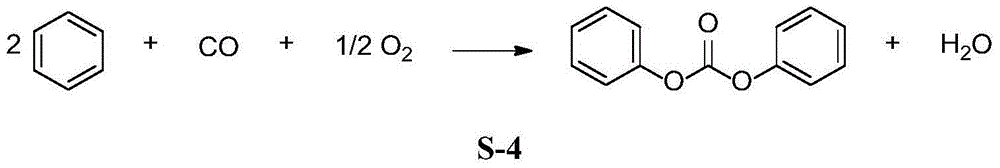

A technology of diphenyl oxalate and dimethyl oxalate is applied in the application field of acid ionic liquid in the preparation of diphenyl oxalate (DPO), and can solve the problem of complex catalyst preparation process, dimethyl carbonate conversion rate of diphenyl carbonate Problems such as low yield and unfavorable industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

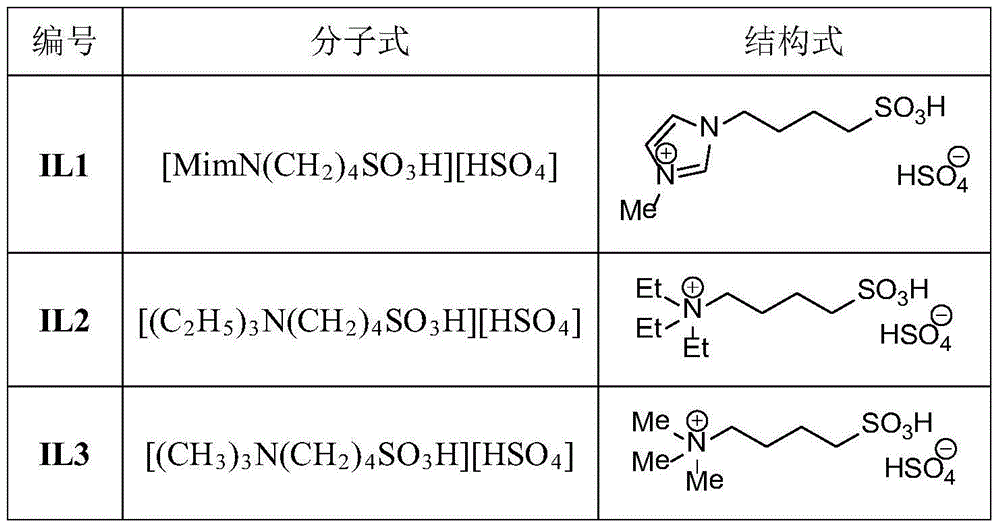

[0044] Embodiment 1, Application of acid ionic liquid in the preparation of diphenyl oxalate (DPO), to Acid ionic liquid [(CH 3 ) 3 N(CH 2 ) 4 SO 3 H][HSO 4 ] as a catalyst (hereinafter referred to as ionic liquid catalyst), the following steps are carried out in sequence:

[0045] In a 250mL three-necked flask equipped with a sealed mechanical stirrer, a thermometer and a reflux condenser, 47.5g (0.5mol) of phenol, 11.8g (0.1mol) of DMO and an ionic liquid catalyst [(CH 3 ) 3 N(CH 2 ) 4 SO 3 H][HSO 4 ] 1.5g (5mmol), stirring and heating up. The 80°C constant temperature circulating water is passed into the reflux condenser tube, and the distillate (mainly the raw material dimethyl oxalate (DMO) with a low boiling point and by-products such as anisole) is collected in the cold trap. The outlet of the cold trap is connected to a three-way valve, and a gas sample is taken at the three-way valve for analysis. The reaction temperature is controlled at 160°C, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com