Immobilized composite unhairing enzyme with leather-making secondary waste as carrier and preparation method thereof

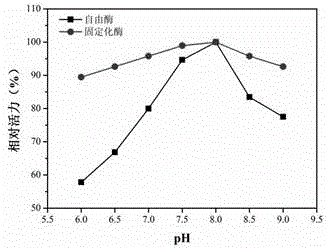

A dehairing enzyme and waste technology, which is applied in the field of preparation of immobilized composite dehairing enzymes, can solve the problems of quality of finished leather, poor process controllability, loose surface strength, etc., so as to improve the use performance, improve the controllability, and reduce the degree of effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

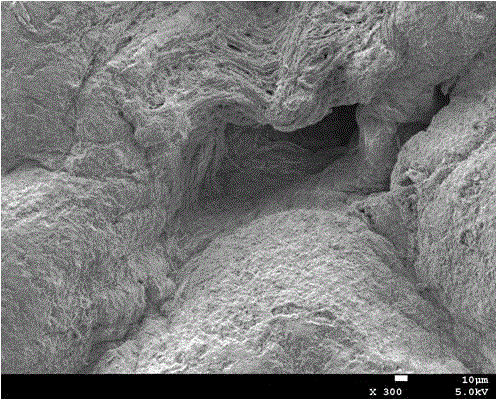

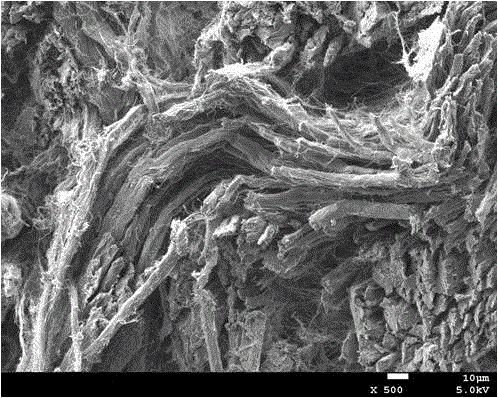

[0030] Soak 100 parts of titanium-containing by-products in deionized water at room temperature for 2 hours, then add 24 parts of glutaraldehyde, shake and react in a water bath at 25°C for 2 hours, filter and wash off the residual glutaraldehyde on the carrier with deionized water; weigh 30 parts of compound depilatory enzymes (21 parts of neutral protease, 6 parts of α-amylase, and 3 parts of trypsin) were dissolved in a buffer solution with a pH value of 6.5 and an ionic strength of 0.1 mol / L to prepare a concentration of 6 % compound depilatory enzyme solution, then centrifuged at 5°C and 8000r / min for 10min, and collected the supernatant clear night; the prepared titanium-containing by-products were added to the composite depilatory enzyme solution, so that the ratio of enzyme to titanium-containing by-products was 0.3, Shake and react in a water bath at 5° C. for 1 hour, filter and wash off the residual composite depilatory enzyme on the carrier with deionized water, that...

Embodiment 2

[0032] Soak 100 parts of zirconium-aluminum by-products in deionized water at room temperature for 2 hours, then add 20 parts of glutaraldehyde, shake and react in a water bath at 35°C for 3 hours, filter and wash off the residual glutaraldehyde on the carrier with deionized water; Take by weighing 40 parts of compound depilatory enzyme (wherein, 30 parts of neutral protease, 6 parts of α-amylase, 4 parts of trypsin) are dissolved in the buffer solution that pH value is 7.0, and ionic strength is 0.05mol / L, is formulated into Concentration is 6% composite depilatory enzyme solution, centrifuge 10min under 5 ℃, 8000r / min then, collect supernatant; Add the prepared zirconium-aluminum by-products into the composite depilatory enzyme solution, make enzyme and zirconium-containing The proportion of aluminum by-products is 0.4, shaken and reacted in a water bath at 15°C for 0.5h, filtered and washed with deionized water to remove the residual composite depilatory enzyme on the carrie...

Embodiment 3

[0034] Soak 100 parts of zirconium-aluminum-titanium by-products in deionized water at room temperature for 4 hours, then add 15 parts of glutaraldehyde, shake and react in a water bath at 15°C for 3 hours, filter and wash off the residual glutaraldehyde on the carrier with deionized water Aldehyde; Take by weighing 20 parts of compound depilatory enzyme (wherein, 16 parts of neutral protease, 2 parts of α-amylase, 2 parts of trypsin) are dissolved in what pH value is 6.5, and ionic strength is in the buffer solution of 0.05mol / L, Prepare a compound hair removal enzyme solution with a concentration of 6%, then centrifuge at 5°C and 8000r / min for 10 minutes, and collect the supernatant; add the prepared zirconium-aluminum-titanium by-products to the compound hair removal enzyme solution to make the enzyme The ratio of zirconium-aluminum-titanium by-products to waste is 0.2, shake and react in a water bath at 25°C for 0.5h, filter and wash off the residual composite depilatory en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com