Desilting device

A technology of dredging device and stirring device, which is applied in the direction of filtration and separation, chemical instruments and methods, and filtration circuit, etc. It can solve the problems of low safety, poor adaptability, and poor working conditions, etc., and achieves a simple separation process and satisfies continuous separation , the effect of high automation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments in the drawings:

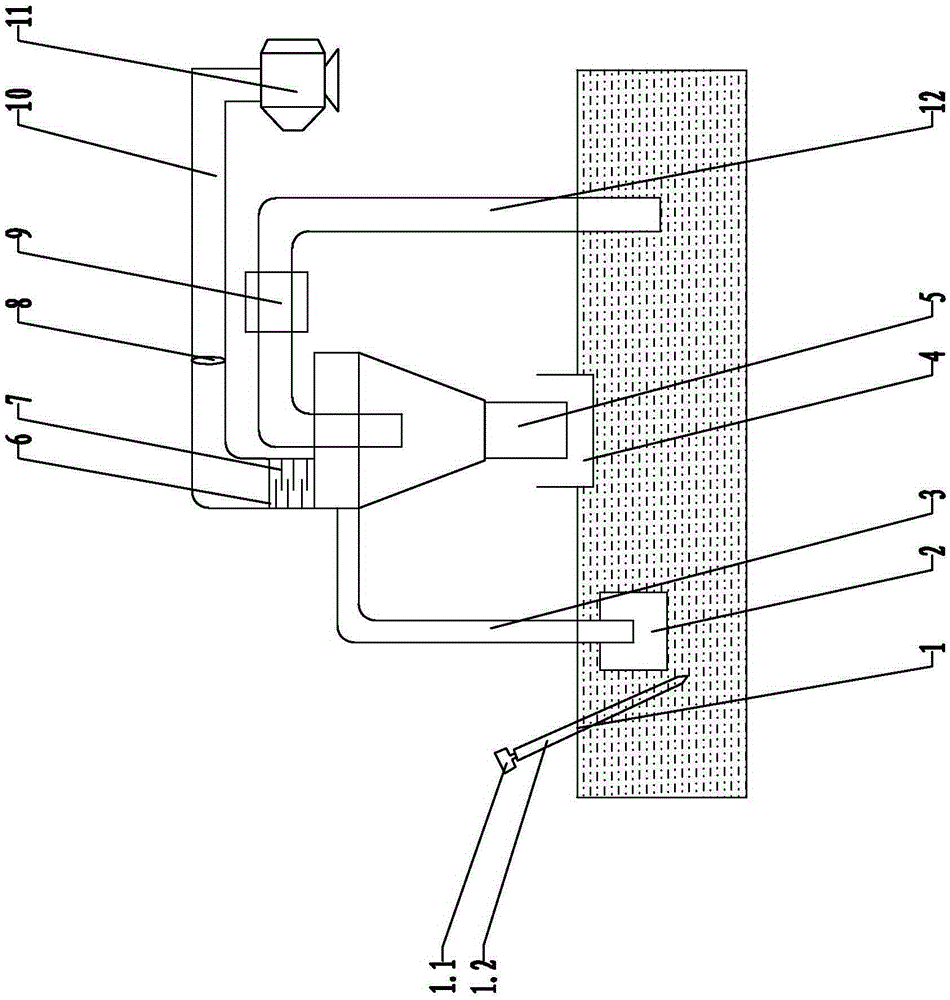

[0015] Such as figure 1 As shown, the present invention mainly includes a cyclone separator 5, the water inlet end of the cyclone separator 5 is connected to a filter 2 through a water suction pipe 3, and a stirring device 1 is provided at the filter 2. The stirring device 1 includes a stirring shaft 1.2 driven by a stirring motor 1.1. In use, it is necessary to use the stirring device 1 to stir from time to time so that the solid-liquid mixture can smoothly pass through the filter 2 and enter the cyclone separator 5.

[0016] A dirt collector 4 is provided directly below the sewage outlet end of the cyclone separator 5, and the dirt collector 4 is used to collect the dirt separated by the cyclone separator 5 to facilitate centralized treatment.

[0017] The water outlet end of the cyclone separator 5 is connected to a drain pipe 12, and a check valve 9 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com