Unfired carbide slag foamed acoustic panel

A technology of calcium carbide slag and sound-absorbing panels, which is used in sound insulation, ceramic products, other household appliances, etc., can solve the problems of the overall strength and bending resistance of the sound-absorbing panels. and other problems, to achieve the effect of strong foaming ability, fast demoulding speed and uniform hole size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with embodiment the present invention will be further described:

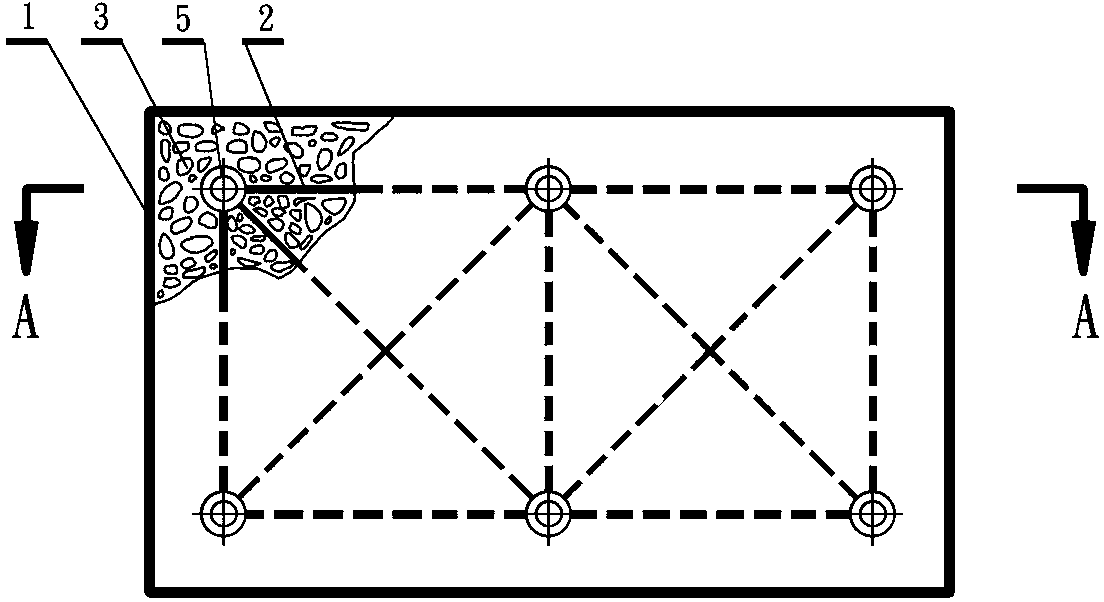

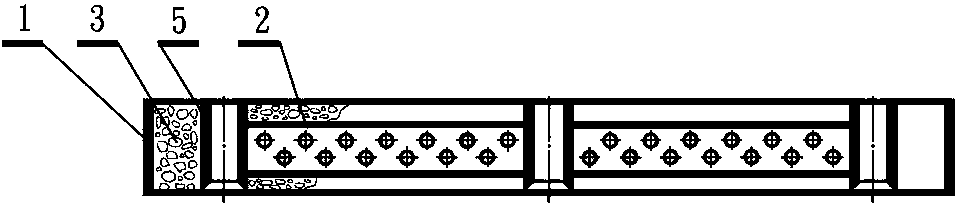

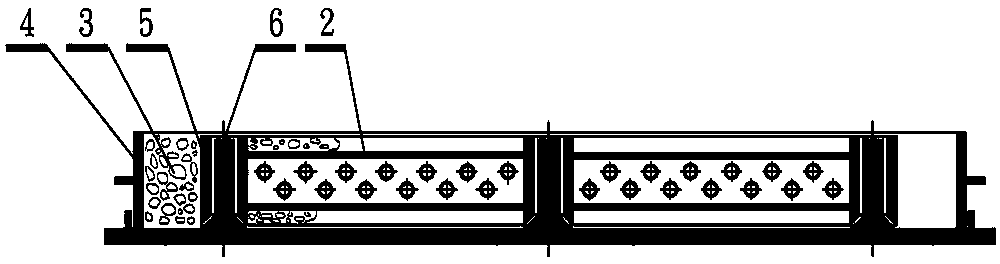

[0040] The non-fired carbide slag foam sound-absorbing panel is a rectangular plate-shaped object 1, which is composed of a built-in frame 2 and a carbide cement foaming agent 3. The built-in frame 2 is designed with 6 short steel pipes 5; the built-in frame 2 is laid flat On the mold 4, after the short steel pipe 5 in the built-in frame 2 is inserted into the column 6, it is poured on the periphery of the built-in frame 2 with a calcium carbide cement foaming agent 3, and after the built-in frame 2 is completely embedded in the interior of the carbide cement foaming agent 3, It is a semi-finished product of non-burning calcium carbide slag foamed sound-absorbing panel; after standing and curing, the semi-finished product of non-burning carbide slag foamed sound-absorbing panel is taken out of the mold, maintained according to the conventional maintenance method of cement products, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com