Diameter reducing bent inner glass tube eccentric heat tube vacuum heat collecting tube

A technology of vacuum heat collecting tubes and inner glass tubes, which is applied in the direction of heating devices, solar thermal devices, solar thermal power generation, etc., can solve problems such as troublesome connection of melting and sealing, insufficient variety of products, etc., to reduce the difficulty of melting and sealing, heat sink Small, heat doubling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

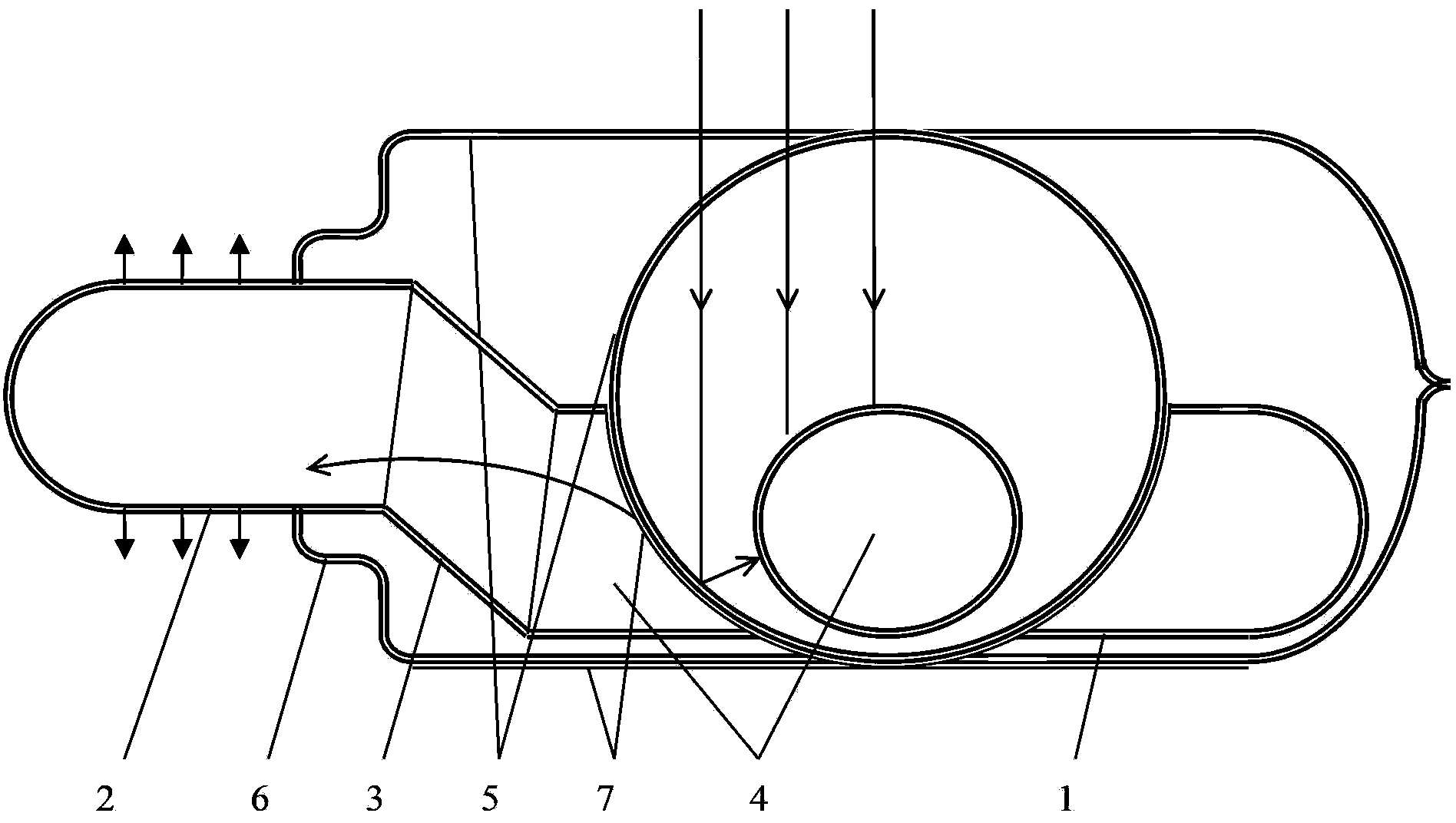

[0014] figure 1 An example of the present invention is given.

[0015] figure 1 In this method, a curved inner glass tube 4 consisting of an eccentric straight section 1, an outer straight section 2, and a curved section 3 connecting the eccentric straight section 1 and the outer straight section 2 is used, and a cover glass tube 5 with one end rounded is embedded. The sleeve arrangement, the waist of the outer straight section 2 and the port of the cover glass tube 5 are melt-sealed and connected to form an eccentric jacket; the cover glass tube 5 contains a reduced diameter section 6 near the sealing; the outer diameter of the reduced diameter section 6 is smaller than the outer straight The diameter of section 2 is 10 mm; the outer straight section 2 protrudes outwards to form a round seal, and the inside of the curved inner glass tube 4 is evacuated and filled with working fluid for sealing; the inside of the eccentric jacket is baked and exhausted and then sealed to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com